1. Description of Full Continuous Refining Line:

Chinese fabricator of improved vegetable oil extractor machine is based on the difference of oil and the impurities in the physical and chemical properties, separate the grease and impurity by some technical ways ,in order to improve the oil edible,storage stability and safety process.Chinese fabricator of improved vegetable oil extractor machine is divided into chemical refining and physical refining.The mini crude oil refinery we adopt suits different kinds of vegetable oil process.According to the raw materials and capacity , we can use batch, continuous, physical and chemical refining design. The product mini crude oil refinery of edible oil equipment can reach first to fourth grade. Guarantee the highest quality in lowest cost.

Capacity of Chinese fabricator of improved vegetable oil extractor machine:5TPD-1000TPD

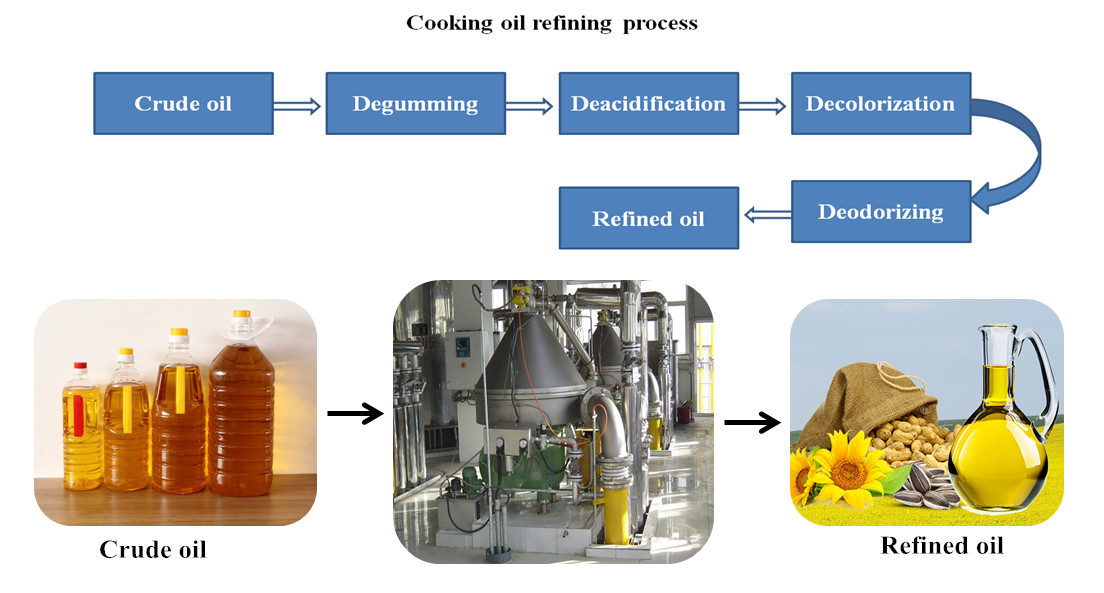

2.Full Continuous Refining Line process:

Main process of Chinese fabricator of improved vegetable oil extractor machine:

**Hydration Deguming & Alkali Refining Deacidification Process

**Continuous Refining Decoloring Process

**Continuous Refining Deodorizing Process

**Automatic Control System of refined canola oil price equipment and so on

3.Advantages of Full Continuous Refining Line:

**The oil fully contacting with the decolorant can improve the decolorization efficiency and reduce the usage of decolorant.

**The continuous and uniform material flows of crude oil refinery will balance the decoloring time and avoid the recovery of grease oxidation and acid value.

**The special mixing structure of decoloring tower won't cause the material dead area, which can avoid the adsorbent sedimentation and pipe blockage.

**The continuous airtight efficient filtration equipment of crude oil refinery has realized the automation of cake discharge and reduced the labor intensity.

**The advanced drying technology of crude oil refinery can reduce the oil content in filter cake.

Chinese fabricator of improved vegetable oil extractor machine

ABOUT LD:

Shandong LD Grain & Oil Machinery Co,. Ltd has set up his own Mechanical design and research institution. It covers 100000 square meters and contains 12 standardized production workshops, more than 100 sets of large scale processing plug welding and assembly equipments.

LD MISSION:

Take quality as the company life, regard user as the god, mutual benefit is what weâre pursuing of all time.

MAIN PROCESS OF SOLVENT EXTRACTION SYSTEM:

ABOUT MAIN SOLVENT EXTRACTION PROCESS:

1. Rotocel extractor: Spray and soak the pre-pressed cake with solvent so that oil fats can be

dissolved in solvent (form miscella). After processing, you can get wet meal and miscella (mixed oil). The pre-pressed cake or flake, firstly enters into the seal auger to avoid the solvent gas escaping. Then material enter into the box-chained loop type extractor and counter-currenting with the solvent, the grease is extracted, and miscella concentration increases from 2% to more than 25%. Then miscella is discharged from extractor, and into miscella filter for filtration. After separating fines, miscella enter into the oil tank, then pump into evaporation system. And the leached meal finally drops in DTDC through buried scraper plate.

2. DTDC toaster: Used to separate the solvent from the wet meal.

Wet meals discharged from the bottom of extractor enter the top of DTDC and land on the predesolventizing trayers where they are heated by the indirect steam, thus, some solvent in meal is evaporated and meal temperature is risen; Predesolventized meals land on predesolventizing trayers where they use the second steam in desolventizing trayers to predesolventize solvent from meal, then, meals enter desolventizing layers in which direct steam is injected.

3. Evaporation process: Pump the miscella ( oil with solvent) into the 1st and 2nd long-tube evaporator, then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.

Using the secondary steam desolventized from DTC desolventizer and produced by steam-jet pump to heat and evaporate micella in the first long-tube evaporator. Export temperature reaches to 58-62â and concentration reaches to more than 65%. Then, micella enters into the second long-tube evaporator in which the temperature is heated to 105-110â by indirect steam and the concentration reaches to more than 95%. Then miscella enters into stripper in which residual solvent in oil will be removed, the export temperature reaches to about 105â and the general volatile of the extracted crude oil is less than 0.30%.

INSTALLATION OF OUR MACHINES IN THAI:

LD CERTIFICATES:

Still have questions?

What should you do??

Do not worry!

SAM is always here!!

Just Contact SAM!!!

Shandong Leader Machinery Co.,Ltd. is one of the leading Manufacturers and Suppliers of Chinese fabricator of improved vegetable oil extractor machine.Shandong Leader Machinery Co.,Ltd. manufacture Chinese fabricator of improved vegetable oil extractor machine making machine using cutting-edge technology, Shandong Leader Machinery Co.,Ltd. have many kinds of Full Continuous Refining Line for you reference,such as Chinese fabricator of improved vegetable oil extractor machine ,Shandong Leader Machinery Co.,Ltd. can meet your different requirement in Full Continuous Refining Line.Welcome to contact Shandong Leader Machinery Co.,Ltd.,contact name:Ms.Myra for a quotation

(Tel/whatsapp:0086-18363092712, Email:[email protected],Skype:leaderfoodmachine2).Welcome to send us your enquiry about capacity for Chinese fabricator of improved vegetable oil extractor machine, inform us raw material you want to use for Chinese fabricator of improved vegetable oil extractor machine,and specific requirements for Chinese fabricator of improved vegetable oil extractor machine.Shandong Leader Machinery Co.,Ltd. will provide you best solution for your project about Full Continuous Refining Line.