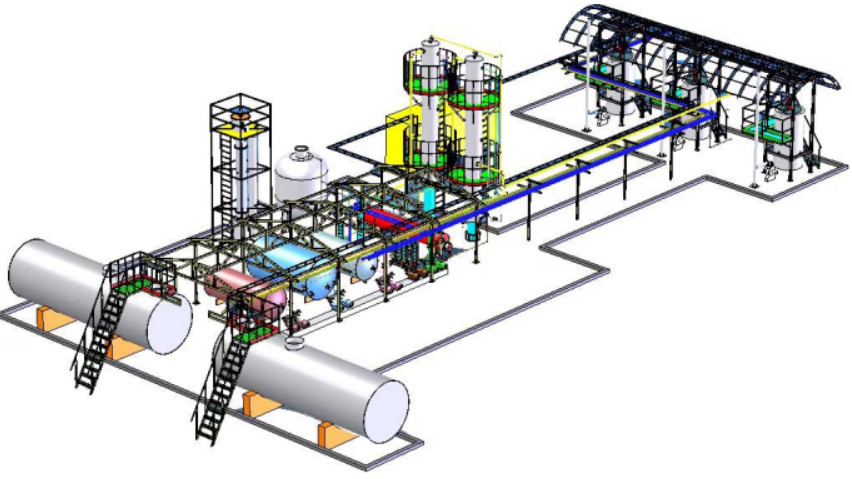

1. Description of Full Continuous Refining Line:

Large scale solvent extraction machine for oil extraction plant is based on the difference of oil and the impurities in the physical and chemical properties, separate the grease and impurity by some technical ways ,in order to improve the oil edible,storage stability and safety process.Large scale solvent extraction machine for oil extraction plant is divided into chemical refining and physical refining.The mini crude oil refinery we adopt suits different kinds of vegetable oil process.According to the raw materials and capacity , we can use batch, continuous, physical and chemical refining design. The product mini crude oil refinery of edible oil equipment can reach first to fourth grade. Guarantee the highest quality in lowest cost.

Capacity of Large scale solvent extraction machine for oil extraction plant:5TPD-1000TPD

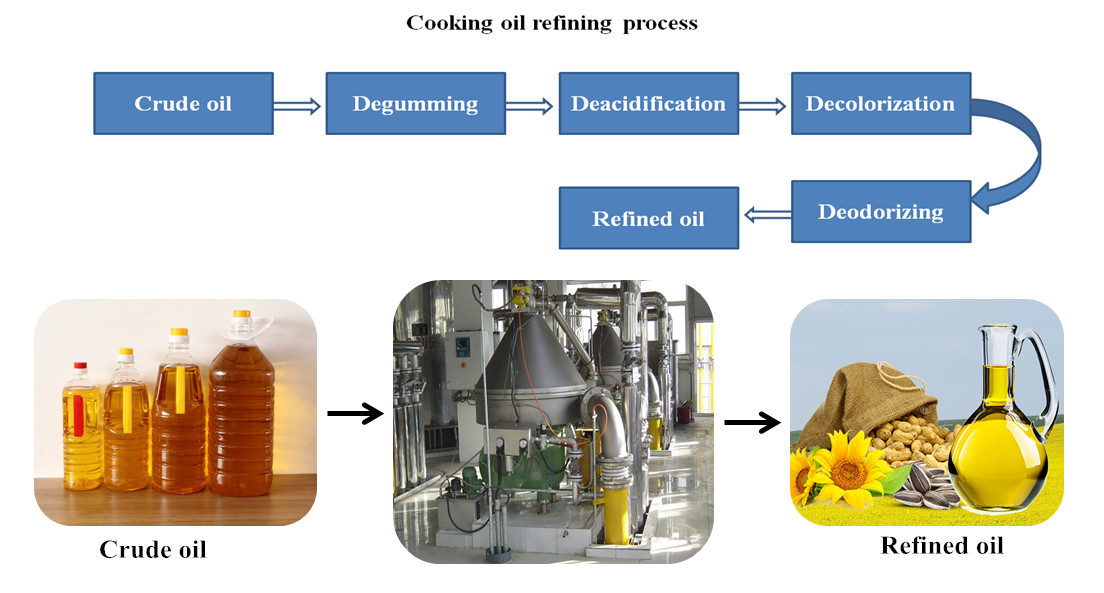

2.Full Continuous Refining Line process:

Main process of Large scale solvent extraction machine for oil extraction plant:

**Hydration Deguming & Alkali Refining Deacidification Process

**Continuous Refining Decoloring Process

**Continuous Refining Deodorizing Process

**Automatic Control System of refined canola oil price equipment and so on

3.Advantages of Full Continuous Refining Line:

**The oil fully contacting with the decolorant can improve the decolorization efficiency and reduce the usage of decolorant.

**The continuous and uniform material flows of crude oil refinery will balance the decoloring time and avoid the recovery of grease oxidation and acid value.

**The special mixing structure of decoloring tower won't cause the material dead area, which can avoid the adsorbent sedimentation and pipe blockage.

**The continuous airtight efficient filtration equipment of crude oil refinery has realized the automation of cake discharge and reduced the labor intensity.

**The advanced drying technology of crude oil refinery can reduce the oil content in filter cake.

Large scale solvent extraction machine for oil extraction plant

What are LD main business scope?

10-500T/H oil material first cleaning,drying and storage section turn-key project;

100-3000 T/D oil pretreatment, shelling and pre-press workshop turnkey project (soybean hot peeling, bean skin crushing; the soybean extrusion, high oil contained pre-press cake extrusion, and high oil contained embryos puffed; of direct puffed). Rice bran production line turn-key project;

100~300TPD Leaching workshop turnkey project (Towline extractor, Rotocel extractor, loop type extractor, DTDC separated machine, the full negative pressure evaporation, paraffin wax recovery, leaching workshop degum, phospholipid concentrate);

30-1000T/D oil continuous grade one or two physical (chemical) refining productionline;

20-3000T/D sunflower oil, rice bran oil, corn germ oil dewaxing turn-key project;

10-200T/D Fatty acid esterification production cooking oil production line.

Brief process of pretreatment of soybean:

Brief process of solvent extraction section:

What is solvent extraction system like?

Rotocel extractor

Drag chain extractor:

Features of rotocel extractor:

1. Stainless steel Grid traies are used to prevent the high density mixed oil from flowing back to the blanking, so it can ensure the extraction effect.

2. The extractor uses special gear racks to deliver the blank, the special designed rotor run in low speed, equipped with low power, it can work steady without noise, also the maintenance is low.

3. The feeder system can adjust the air-locks and the speed of main engine, so there will be some blank in the buffer bin, and itâs helpful to produce negative pressure in the extractor, meanwhile the solvent wonât leak out.

4. The advanced mixed oil circulation theory is good to reduce the input of fresh solvent, and that decreases the residual oil in the dregs, it can also improve the density of the mixed oil. It can save the energy through decreasing the amount of evaporation.

5. The high bed layers are designed to form immersion extraction and decrease the amount of dregs in mixed oil. It can improve the quality of crude oil and reduce the scaling in the evaporation system.

6. Itâs suitable for the extraction of various pre-pressed cake.

Brief process of refining section:

What will be product oil like?

What certificates do LD have?

Still have questions?

What should you do??

Do not worry!

SAM is always here!!

Just knock me!!!

Shandong Leader Machinery Co.,Ltd. is one of the leading Manufacturers and Suppliers of Large scale solvent extraction machine for oil extraction plant.Shandong Leader Machinery Co.,Ltd. manufacture Large scale solvent extraction machine for oil extraction plant making machine using cutting-edge technology, Shandong Leader Machinery Co.,Ltd. have many kinds of Full Continuous Refining Line for you reference,such as Large scale solvent extraction machine for oil extraction plant ,Shandong Leader Machinery Co.,Ltd. can meet your different requirement in Full Continuous Refining Line.Welcome to contact Shandong Leader Machinery Co.,Ltd.,contact name:Ms.Myra for a quotation

(Tel/whatsapp:0086-18363092712, Email:[email protected],Skype:leaderfoodmachine2).Welcome to send us your enquiry about capacity for Large scale solvent extraction machine for oil extraction plant, inform us raw material you want to use for Large scale solvent extraction machine for oil extraction plant,and specific requirements for Large scale solvent extraction machine for oil extraction plant.Shandong Leader Machinery Co.,Ltd. will provide you best solution for your project about Full Continuous Refining Line.