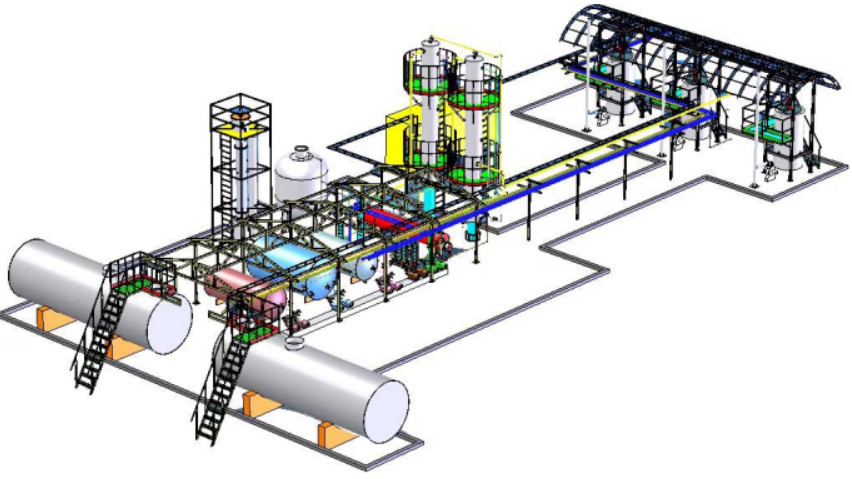

1. Description of Full Continuous Refining Line:

Multi-functional small scale sunflower oil press fabricator is based on the difference of oil and the impurities in the physical and chemical properties, separate the grease and impurity by some technical ways ,in order to improve the oil edible,storage stability and safety process.Multi-functional small scale sunflower oil press fabricator is divided into chemical refining and physical refining.The mini crude oil refinery we adopt suits different kinds of vegetable oil process.According to the raw materials and capacity , we can use batch, continuous, physical and chemical refining design. The product mini crude oil refinery of edible oil equipment can reach first to fourth grade. Guarantee the highest quality in lowest cost.

Capacity of Multi-functional small scale sunflower oil press fabricator:5TPD-1000TPD

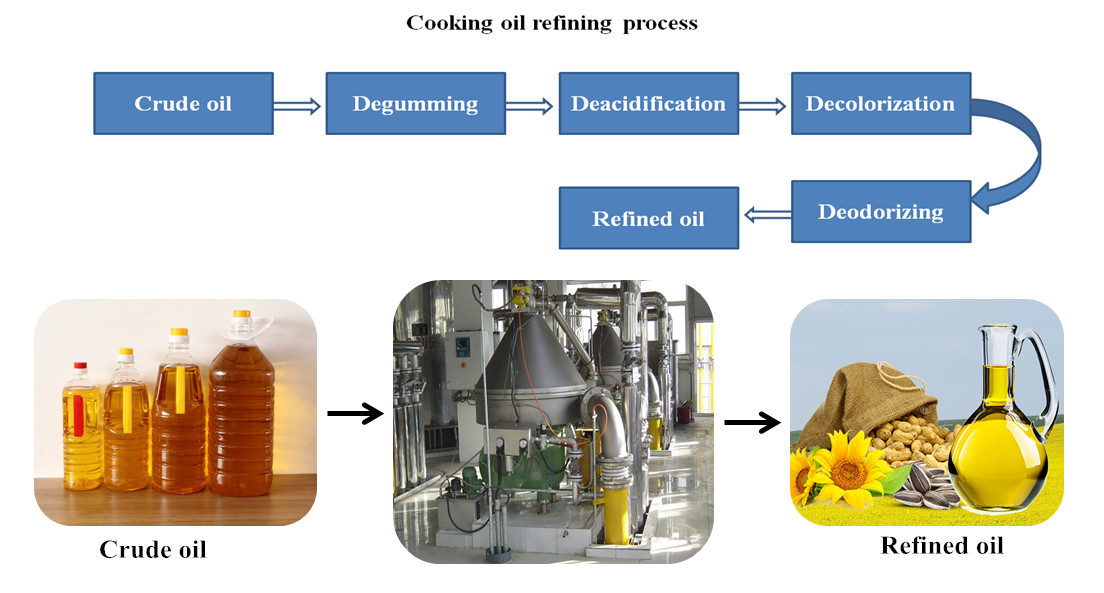

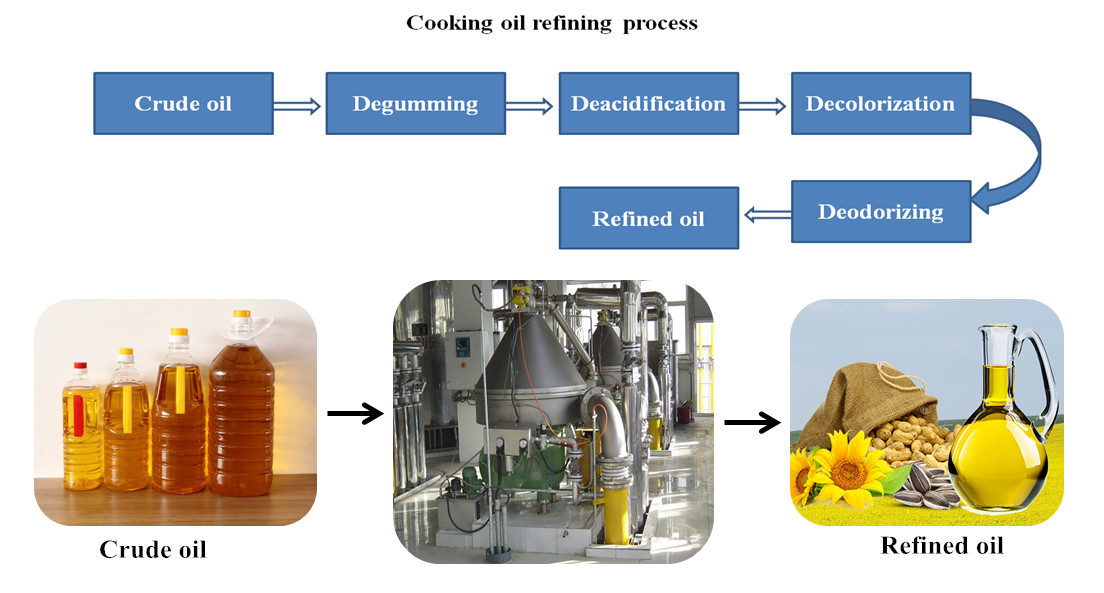

2.Full Continuous Refining Line process:

Main process of Multi-functional small scale sunflower oil press fabricator:

**Hydration Deguming & Alkali Refining Deacidification Process

**Continuous Refining Decoloring Process

**Continuous Refining Deodorizing Process

**Automatic Control System of refined canola oil price equipment and so on

3.Advantages of Full Continuous Refining Line:

**The oil fully contacting with the decolorant can improve the decolorization efficiency and reduce the usage of decolorant.

**The continuous and uniform material flows of crude oil refinery will balance the decoloring time and avoid the recovery of grease oxidation and acid value.

**The special mixing structure of decoloring tower won't cause the material dead area, which can avoid the adsorbent sedimentation and pipe blockage.

**The continuous airtight efficient filtration equipment of crude oil refinery has realized the automation of cake discharge and reduced the labor intensity.

**The advanced drying technology of crude oil refinery can reduce the oil content in filter cake.

Multi-functional small scale sunflower oil press fabricator

FINAL PRODUCT OIL:

INTRODUCTION:

6YL series spiral oil press is mainly composed of 7 major parts of screw axis, press cage, feed mechanism, cake yielding mechanism. transmission system, electric control part and vacuum filter part.

All the parts are assembled on the frame and screwed as a whole.

DISPLAY OF LD PEANUT OIL PRESS MACHINE:

DESCRIPTION OF SCREW OIL PRESS

1. 6YL series screw oil press are advanced oil processing machinery, characterized by their simple design, wide suitablity, convenient operation and also high productivity and high oil outputrate.

2. They can be used for various materials, such as Peanut, Soybean, Grape seeds, Rape seeds, Sunflower seeds, Jatropha seeds, Palm kernel, etc.

3. They are suitable for medium and small sized oil extruding workshops or professional farmers.

4. They can be used for pre-pressing submerging oil workshops.

STRUCTURE OF LD INTEGRATED SCREW PRESS:

LD SCREW PRESS OPERATING PRINCIPLES:

1. When oil press is on, material enters the extruding chamber from the hopper and then moves forwards by the rotating pressing screw and is pressed.

2. Under hightemperature condition in the chamber, there is quite strong friction among press screw, chamber and the oil materials.

3. On the other hand, root diameter of the pressing screw carries larger from one end to the other.

4. Hence when rotating, the thread not only pushes particles moving forwards but also turns them outwards as well.

5. Meanwhile, particles adjacent the screw will rotate along with screwâs rotating, causing every particle inside the chamber to possess different speed.

6. Therefore, relative movement among particles creates neat which is necessary during manufacturing because of helping protein change property, damage colloid, increase plasticity, decrease oilâs elasticity, resulting in high oil.

FEATURES OF OIL PRESS:

1. Energy Saving: The electric power can be reduced by 40% under the same output.

2. Labor Saving: 60% labor can be saved under the same output.

3. Widely Usage: The machine is multi-function. It can process more than 20 kinds of oil crops.

4. Pure Oil: Vaccum filter can filter the residue and ensure the oil quality. The oil can meet the standard of health quarantine.

5. Small Area Covering: 10 ~ 20 m2 can meet the production needs.

LD SHIPPING:

Still have questions?

What should you do??

Do not worry!

SAM is always here!!

Just Contact SAM!!!

Shandong Leader Machinery Co.,Ltd. is one of the leading Manufacturers and Suppliers of Multi-functional small scale sunflower oil press fabricator.Shandong Leader Machinery Co.,Ltd. manufacture Multi-functional small scale sunflower oil press fabricator making machine using cutting-edge technology, Shandong Leader Machinery Co.,Ltd. have many kinds of Full Continuous Refining Line for you reference,such as Multi-functional small scale sunflower oil press fabricator ,Shandong Leader Machinery Co.,Ltd. can meet your different requirement in Full Continuous Refining Line.Welcome to contact Shandong Leader Machinery Co.,Ltd.,contact name:Ms.Myra for a quotation

(Tel/whatsapp:0086-18363092712, Email:[email protected],Skype:leaderfoodmachine2).Welcome to send us your enquiry about capacity for Multi-functional small scale sunflower oil press fabricator, inform us raw material you want to use for Multi-functional small scale sunflower oil press fabricator,and specific requirements for Multi-functional small scale sunflower oil press fabricator.Shandong Leader Machinery Co.,Ltd. will provide you best solution for your project about Full Continuous Refining Line.