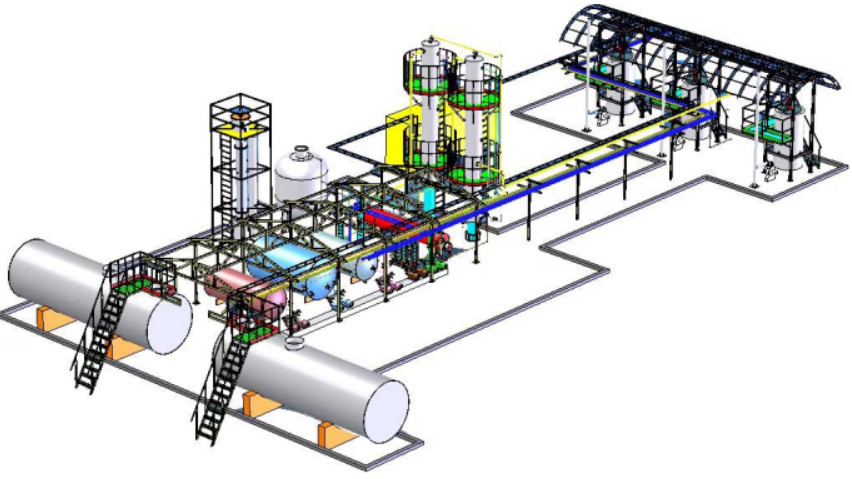

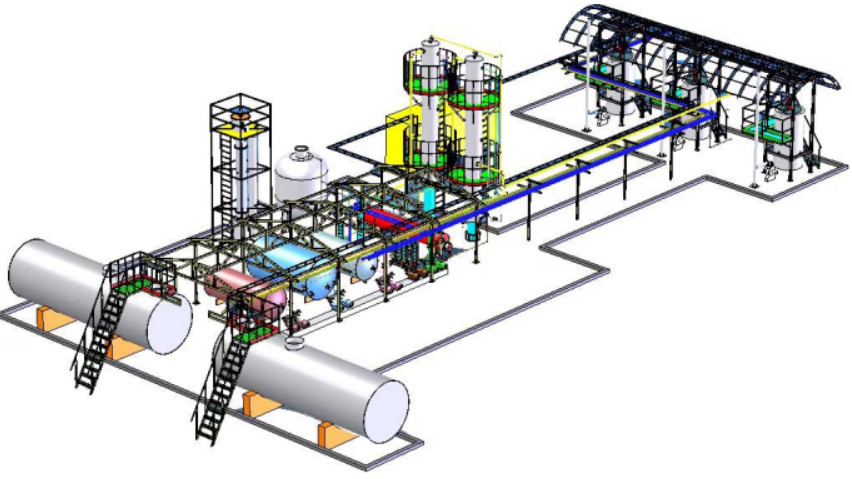

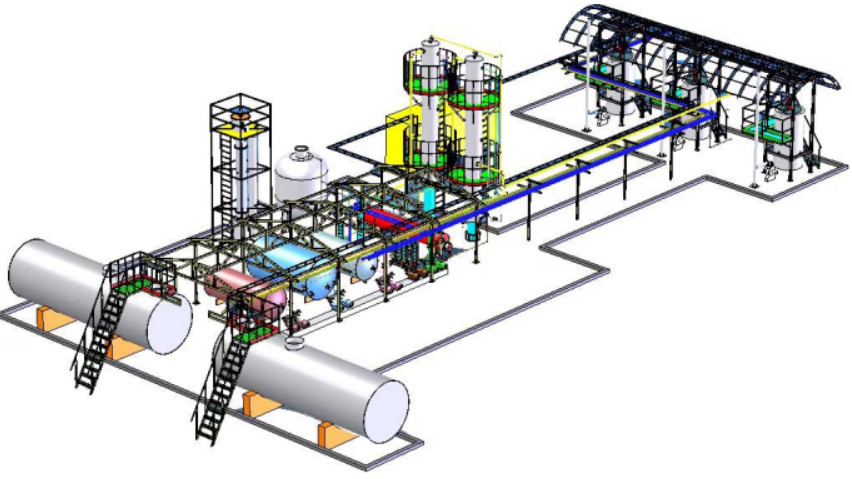

1. Description of Full Continuous Refining Line:

China advanced technology oil seed oil making machine is based on the difference of oil and the impurities in the physical and chemical properties, separate the grease and impurity by some technical ways ,in order to improve the oil edible,storage stability and safety process.China advanced technology oil seed oil making machine is divided into chemical refining and physical refining.The mini crude oil refinery we adopt suits different kinds of vegetable oil process.According to the raw materials and capacity , we can use batch, continuous, physical and chemical refining design. The product mini crude oil refinery of edible oil equipment can reach first to fourth grade. Guarantee the highest quality in lowest cost.

Capacity of China advanced technology oil seed oil making machine:5TPD-1000TPD

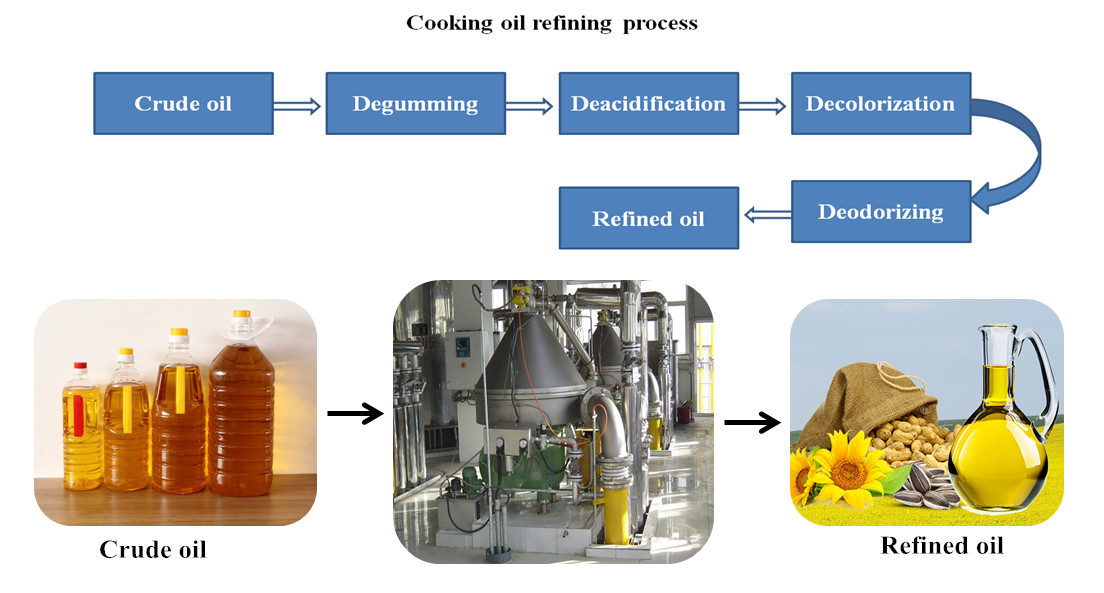

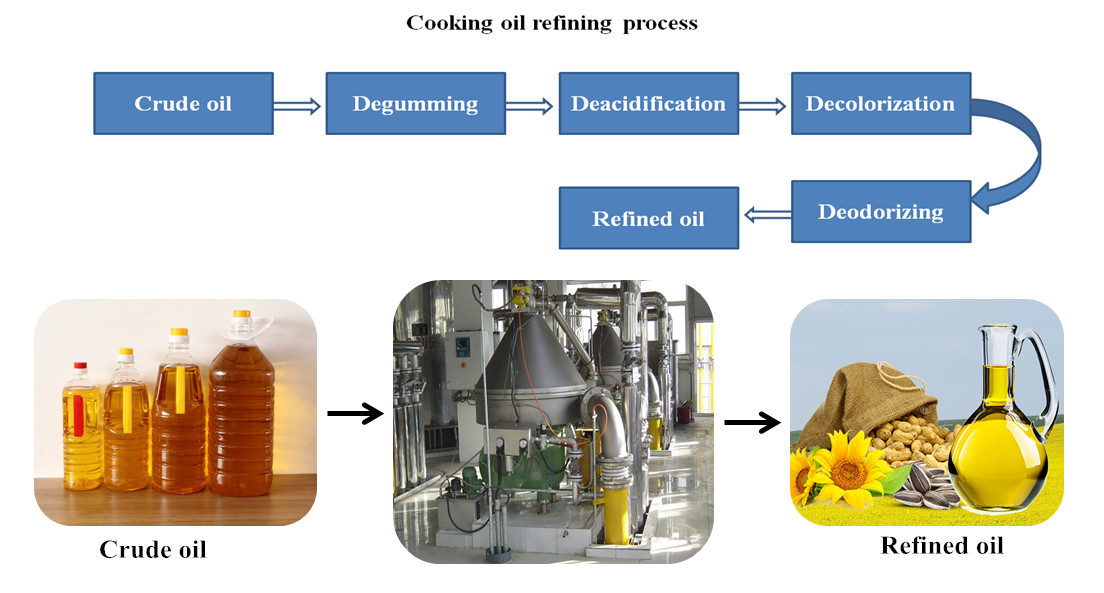

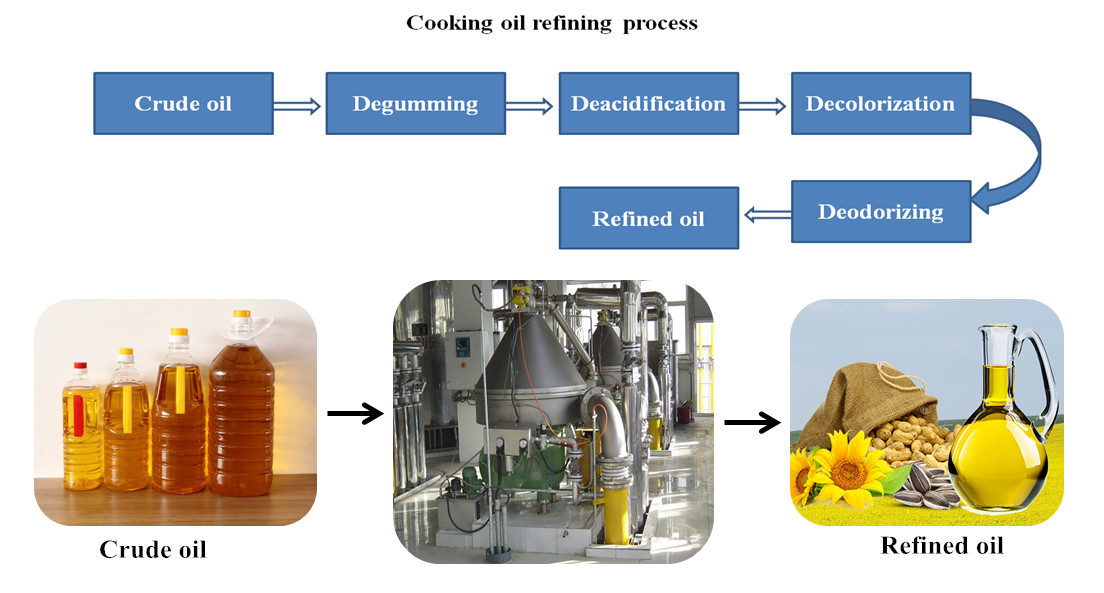

2.Full Continuous Refining Line process:

Main process of China advanced technology oil seed oil making machine:

**Hydration Deguming & Alkali Refining Deacidification Process

**Continuous Refining Decoloring Process

**Continuous Refining Deodorizing Process

**Automatic Control System of refined canola oil price equipment and so on

3.Advantages of Full Continuous Refining Line:

**The oil fully contacting with the decolorant can improve the decolorization efficiency and reduce the usage of decolorant.

**The continuous and uniform material flows of crude oil refinery will balance the decoloring time and avoid the recovery of grease oxidation and acid value.

**The special mixing structure of decoloring tower won't cause the material dead area, which can avoid the adsorbent sedimentation and pipe blockage.

**The continuous airtight efficient filtration equipment of crude oil refinery has realized the automation of cake discharge and reduced the labor intensity.

**The advanced drying technology of crude oil refinery can reduce the oil content in filter cake.

Vegetable seeds

Oil seed oil making machine

1. Widely used to press various kind of oil materials such as sunflower seeds, baobab seeds, neem seeds, sesame, peanut, sunflower seeds,rapeseeds, mustard, castorseeds, copra kernels,palm, coconut, walnuts, soybean, cotton seeds as well as rice bran, etc.

2.It is easy to operate. When operating, you should follow the instructions strictly.

3.The oil residual rate is less than 6.5%. The cake thickness can be adjusted as yourequested.

Detailed Images

Detailed ImagesOil seed oil making machine----Pressing Method

Pressing method was calledâ physical squeeze methodâ, it used external force to extract out the oil from oilseed without any chemical solvent, so that avoid of the residual organic solvent in the oil.Pressing technology retain flaxseed oil effective constituent at the greatest extentââpolyunsaturated acid and protein, dietary fiber, microelement and more other nutritional ingredient which is good for people health, and it special used to supple people health care.And pressing method also divide into âcold pressâ and âhot pressâ.

Oil seed oil making machine ----Cold press

It means that under low temperature, adapt to physical huge presser to extract vegetable oil, without the traditional high temperature frying and cooking process, so the oil was distributed in the underformed protein cell, it contains rich flaxseed inherent ingredient( flaxseed and more nutritional ingredient).

Oil seed oil making machine ----Hot press

Hot press: it means that the oilseed after high temperature frying and cooking, under physical pressing to get oil, it is a traditional pressing technology, with high oil yield. Good taste, high oil yield.To increase oil yield, improve oil taste, and rich flavor.According to the customers' requiremnts.

Oil seed oil making machine ----Cold press technology introduction

Flaxseed harvest/screen ------Flaxseed------Cleaning------Husking-----Crusher------Press with low temperature-----Crude Oil-----Coarse filtration------Fine filtration-----Crystallization and Maturation with low temperature-----Low temperature filtration----Cold flaxseed oil

Cold pressing technological characteristics :

1. To avoid of the dangerous that was brought by oil and carbohydrate matter degradation and protein denaturation, which caused by high temperature.

2. To avoid of the deep color and verbrennen phenomenon, which caused by high temperature.3. Passed multiple filtration, avoid in the process of hot press method of degumming, deacid and decoloring chemicals caused directly contact with a effective components and second pollution.

4. To avoid of high temperature distillation deodorization, Effectively prevent the high temperature of polyunsaturated fatty acids in linseed oil-----α- linolenic acid damage, Effectively retain natural complete nutrients, more for easy absorption by human body and nutritional supplements.

Oil seed oil making machine ----Hot press technology introduction

Flaxseed harvest/screen ------Flaxseed------Cleaning------Husking-----Crusher-----Cooker ------Presser-----Crude Oil-----Coarse filtration------Fine filtration-----Degumming----Washing----Dehydration-----Decoloring------Deodorization------Hot pressed Flaxseed Oil

Hot press technological characteristics:

1. To increase oil yield, improve oil taste, and rich flavor.

2. Lead to high temperature oxidative polymerization easily, decomposed and produced peroxide and other harmfull substance, broken the nutritional ingredients.

3. More impurities, such as FFA, phospholipid and more, affect the oil appearance color and oil interior quality.

Pretreatment Machine-----Destoner

Pretreatment Machine-----Vibration Screen

Pretreatment Machine----Crusher

Pretreatment Machine-----Cooker

Filtraction Machine-----Plate Filter

Filtraction Machine-----Crystallizer And Maturator

Oil Refining Machine-----Leaf Filter

Oil Refining Machine-----Degumming To Deodorization

Oil seed oil making machine adapt to many mateirals,such as peanut,soybean,corn germ,sunflower,sesame, castor, cottonseed, coconut, black seed, rapeseed, and more oilseeds.

Packing & Delivery

Our Company

Our Company

LD Group Introduction:

Shandong LD grain and oil machinery co., LTD is a company specializing in the production of grain and oil machinery and equipment, scientific research, manufacturing, sales for the integration of large-scale private enterprises, the company with the mechanical design and research institute of Jinan province, Jinan university of technology (the former college of food) university-enterprise cooperation, carried out for a long time in oil machinery, preparing protein, lecithin extraction and other aspects of the research and development and application of new technology.

Company has oil machinery design institute, the ministry of oil press, large oil complete sets of equipment, international trade, machinery and equipment production.Business involves the small oil mill series, grain and oil engineering design, equipment manufacture and installation, project contracting, technical services, new product development, oil by-products deep processing, etc.

Company is located in the capital of Jinan province.

LD Main Business:

⢠10-500T/H oil material first cleaning,drying and storage section turn-key project.

⢠100-3000 T/D oil pretreatment, shelling and pre-press workshop turnkey project (soybean hot peeling, bean skin crushing; the soybean extrusion, high oil contained pre-press cake extrusion, and high oil contained embryos puffed; of direct puffed). Rice bran production line turn-key project.

⢠Leaching workshop turnkey project (Towline extractor, Rotocel extractor, loop type extractor, DTDC separated machine, the full negative pressure evaporation, paraffin wax recovery, leaching workshop degum, phospholipid concentrate).

⢠30-1000T/D oil continuous grade two or one physical (chemical) refining production line.

⢠10-600T/D sunflower oil, rice bran oil, corn germ oil dewaxing turn-key project

⢠10-200T/D Fatty acid esterification production cooking oil production line.

⢠1-100T/H Palm Oil Mill Turn-key Plant

Shandong Leader Machinery Co.,Ltd. is one of the leading Manufacturers and Suppliers of China advanced technology oil seed oil making machine.Shandong Leader Machinery Co.,Ltd. manufacture China advanced technology oil seed oil making machine making machine using cutting-edge technology, Shandong Leader Machinery Co.,Ltd. have many kinds of Full Continuous Refining Line for you reference,such as China advanced technology oil seed oil making machine ,Shandong Leader Machinery Co.,Ltd. can meet your different requirement in Full Continuous Refining Line.Welcome to contact Shandong Leader Machinery Co.,Ltd.,contact name:Ms.Myra for a quotation

(Tel/whatsapp:0086-18363092712, Email:[email protected],Skype:leaderfoodmachine2).Welcome to send us your enquiry about capacity for China advanced technology oil seed oil making machine, inform us raw material you want to use for China advanced technology oil seed oil making machine,and specific requirements for China advanced technology oil seed oil making machine.Shandong Leader Machinery Co.,Ltd. will provide you best solution for your project about Full Continuous Refining Line.