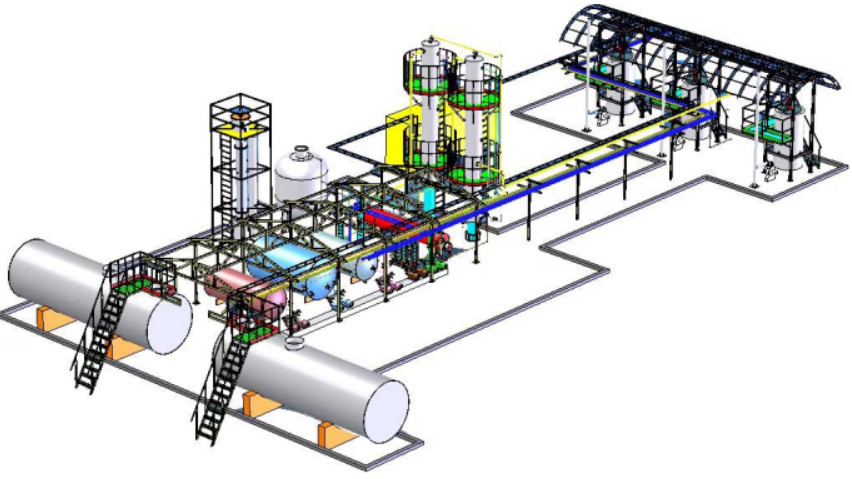

1. Description of Full Continuous Refining Line:

Improved complete rapeseed screw oil press is based on the difference of oil and the impurities in the physical and chemical properties, separate the grease and impurity by some technical ways ,in order to improve the oil edible,storage stability and safety process.Improved complete rapeseed screw oil press is divided into chemical refining and physical refining.The mini crude oil refinery we adopt suits different kinds of vegetable oil process.According to the raw materials and capacity , we can use batch, continuous, physical and chemical refining design. The product mini crude oil refinery of edible oil equipment can reach first to fourth grade. Guarantee the highest quality in lowest cost.

Capacity of Improved complete rapeseed screw oil press:5TPD-1000TPD

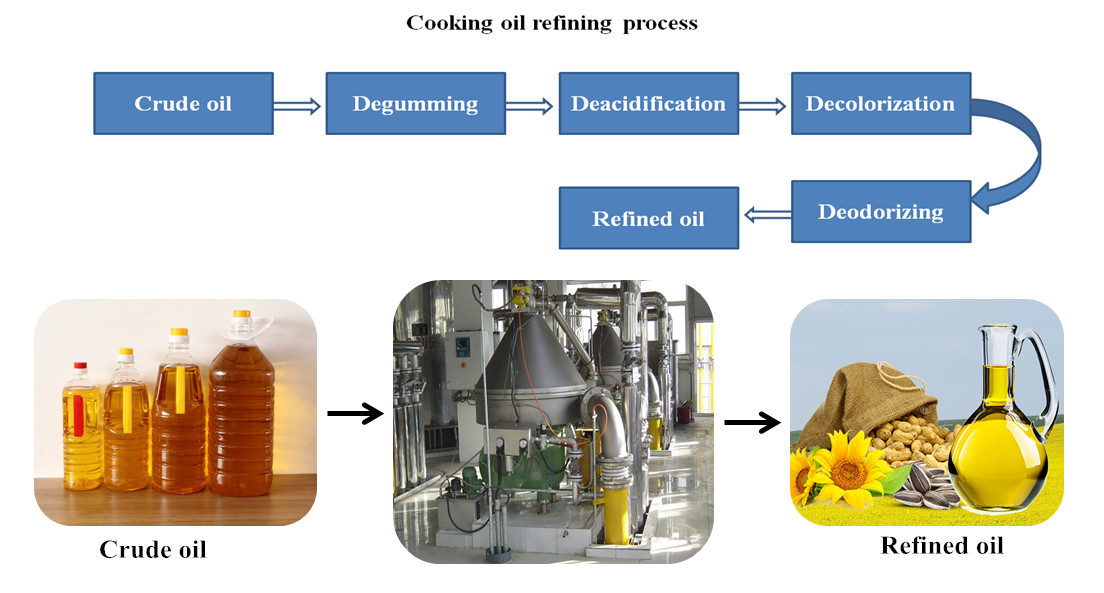

2.Full Continuous Refining Line process:

Main process of Improved complete rapeseed screw oil press:

**Hydration Deguming & Alkali Refining Deacidification Process

**Continuous Refining Decoloring Process

**Continuous Refining Deodorizing Process

**Automatic Control System of refined canola oil price equipment and so on

3.Advantages of Full Continuous Refining Line:

**The oil fully contacting with the decolorant can improve the decolorization efficiency and reduce the usage of decolorant.

**The continuous and uniform material flows of crude oil refinery will balance the decoloring time and avoid the recovery of grease oxidation and acid value.

**The special mixing structure of decoloring tower won't cause the material dead area, which can avoid the adsorbent sedimentation and pipe blockage.

**The continuous airtight efficient filtration equipment of crude oil refinery has realized the automation of cake discharge and reduced the labor intensity.

**The advanced drying technology of crude oil refinery can reduce the oil content in filter cake.

Improved complete rapeseed screw oil press

LD clients' workshop:

Parameters about LD press machine:

| Model | 6YL-80 | 6YL-100 | 6YL-120 | 6YL-130 |

| Screw speed | 30-45r/min | 30-40 r/min | 30-40 r/min | 28-40 r/min |

| gear ratio | 14/42x19/57=1:6.63 | 15/40x15/55=1:9.78 | 15/34x15/55=1:9.59 | 15/38x19/48=1:7.38 |

| Dimension | 1650x1150x1750 | 1950x1300x1900 | 2050x1350x2000 | 2200x1600x2150 |

| Productivity | 80-150kg/h | 150-250kg/h | 200-300kg/h | 250-400kg/h |

| Power | Y160L-6-5.5KW | Y160M-6-7.5KW | Y160L-6-11KW | Y180L-6-15KW |

| Vacuum pump | Y90S-4-0.55KW | Y90S-4-1.1KW | Y100L1-4-1.5KW | Y100L1-4-2.2KW |

| Heater | 2KW | 3KW | 3.3KW | 3.8KW |

Features:

1. Stainless steel used on the surface to reach the standard of food hygiene.

2. cold lower temperature keep in pressing technology.

3. Durable, for 1 year free after-sales service. Include replace the parts costs.

4. A double helix oil press equals two oil press, can obtain double benefit

5. High quality parts, stable oil pressing effect, saving the maintenance cost.

6. Military industrial manufacturing, quality chrome materials, quality trustworthy.

Still have questions?

What should you do??

Do not worry!

SAM is always here!!

Just Contact SAM!!!

Shandong Leader Machinery Co.,Ltd. is one of the leading Manufacturers and Suppliers of Improved complete rapeseed screw oil press.Shandong Leader Machinery Co.,Ltd. manufacture Improved complete rapeseed screw oil press making machine using cutting-edge technology, Shandong Leader Machinery Co.,Ltd. have many kinds of Full Continuous Refining Line for you reference,such as Improved complete rapeseed screw oil press ,Shandong Leader Machinery Co.,Ltd. can meet your different requirement in Full Continuous Refining Line.Welcome to contact Shandong Leader Machinery Co.,Ltd.,contact name:Ms.Myra for a quotation

(Tel/whatsapp:0086-18363092712, Email:[email protected],Skype:leaderfoodmachine2).Welcome to send us your enquiry about capacity for Improved complete rapeseed screw oil press, inform us raw material you want to use for Improved complete rapeseed screw oil press,and specific requirements for Improved complete rapeseed screw oil press.Shandong Leader Machinery Co.,Ltd. will provide you best solution for your project about Full Continuous Refining Line.