1. Description of Full Continuous Refining Line:

2016 LD company vegetable seed oil re-refining plant is based on the difference of oil and the impurities in the physical and chemical properties, separate the grease and impurity by some technical ways ,in order to improve the oil edible,storage stability and safety process.2016 LD company vegetable seed oil re-refining plant is divided into chemical refining and physical refining.The mini crude oil refinery we adopt suits different kinds of vegetable oil process.According to the raw materials and capacity , we can use batch, continuous, physical and chemical refining design. The product mini crude oil refinery of edible oil equipment can reach first to fourth grade. Guarantee the highest quality in lowest cost.

Capacity of 2016 LD company vegetable seed oil re-refining plant:5TPD-1000TPD

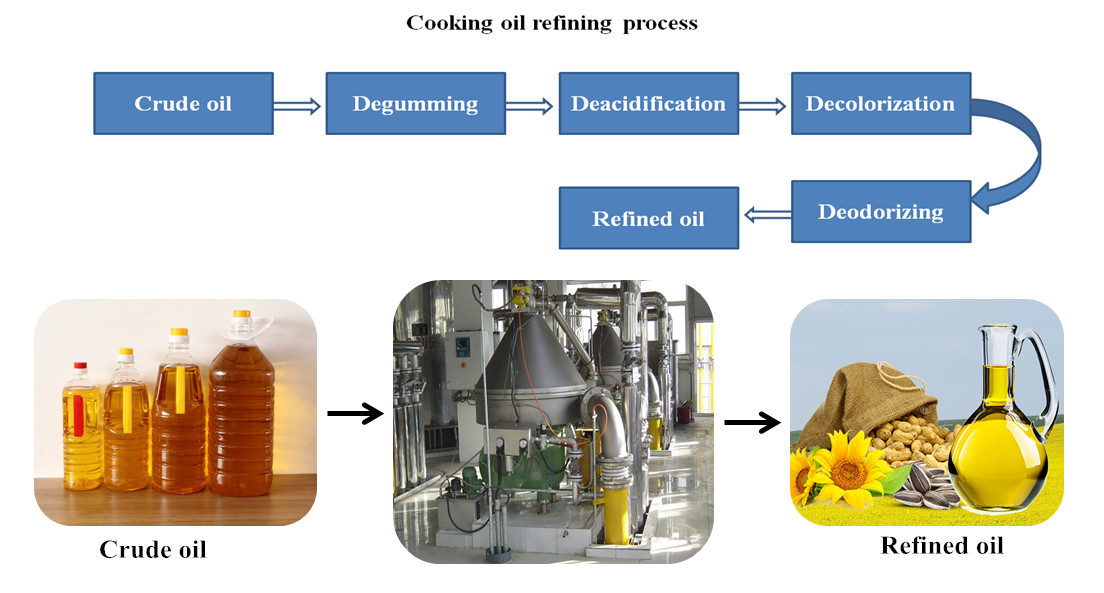

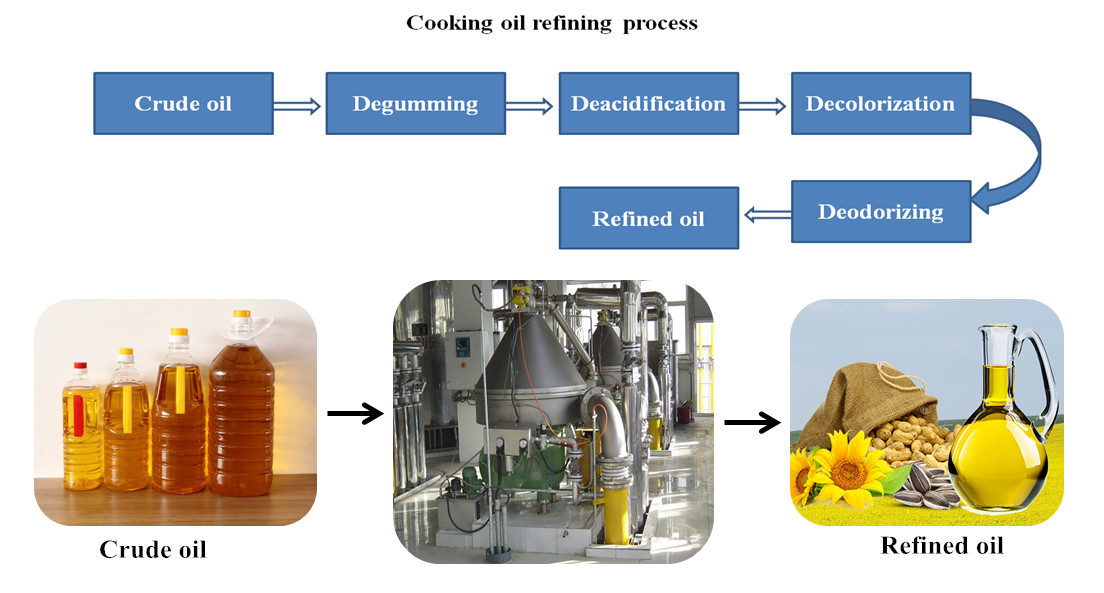

2.Full Continuous Refining Line process:

Main process of 2016 LD company vegetable seed oil re-refining plant:

**Hydration Deguming & Alkali Refining Deacidification Process

**Continuous Refining Decoloring Process

**Continuous Refining Deodorizing Process

**Automatic Control System of refined canola oil price equipment and so on

3.Advantages of Full Continuous Refining Line:

**The oil fully contacting with the decolorant can improve the decolorization efficiency and reduce the usage of decolorant.

**The continuous and uniform material flows of crude oil refinery will balance the decoloring time and avoid the recovery of grease oxidation and acid value.

**The special mixing structure of decoloring tower won't cause the material dead area, which can avoid the adsorbent sedimentation and pipe blockage.

**The continuous airtight efficient filtration equipment of crude oil refinery has realized the automation of cake discharge and reduced the labor intensity.

**The advanced drying technology of crude oil refinery can reduce the oil content in filter cake.

2016 LD company vegetable seed oil re-refining plant

Product Description

Refined edible oil

What is vegetable seed oil re-refining plant ?

The crude oil obtained either from expellers or solvent extraction plant contains impurities, which must be removed to make the oil edible, more palatable and stable against rancidity upon storage. The process of removing these impurities is called refining.

What is vegetable seed oil re-refining plant ?

1)chemical refining 2) physical refining 3)chemical-physical refining

vegetable seed oil re-refining plant detail describle:

(1). Refining pot: used to P-acid de-gumming, alkali refining de-acid and

water rinsing.

(2).De-color pot: used to remove off pigments, bleaching oils and grease de-hydrate.

(3).De-odor pot: used to remove off oils odor, foreign smells (stainless made) Heat transfer oil stove: supply each device production needing heat energy, temperature reach above 280 ° C.

(4).Steam generator: produce the needing steam for de-odoring and distillation.

(5).Vacuum pump: supply needing vacuum for dehydrate, de-color, de-odor. Vacuum degree can

reach above 755mmHg.

(6).Press filter: filter clay, filter out clear oil.

(7).Air compressor: blow dry bleached clay, blow empty the leftover oil in

vegetable seed oil re-refining plant operation process:

Step 1.Degumming with water to remove the easily hydratable phospholipids and metals.

Step 2.Addition of a small amount of phosphoric or citric acid to convert the remaining non-hydralable phospholipids (Ca, Mg salts) into hydratable phospholipids.

Step 3.Neutralising of the free fatty acids with a slight excess of sodium hydroxide solution, followed by the washing out of soaps and hydrated phospholipids.

Step 4.Bleaching with natural or acid-activated clay minerals to adsorb colouring components and to decompose hydroperoxides.

Step 5.Deodorising to remove volatile components, mainly aldehydes and ketones, with low threshold values for detection by taste or smell. Deodorisation is essentially a steam distillation process carried out at low pressures (2-6 mbar) and elevated temperatures (180-220°C).

What is LD vegetable seed oil re-refining plant Advantages ?

Safety:

1) We use auto welding machine to make the reactor,which can quarrantee the quality of welding seam,avoid cracking and has a long life for about 8 years.

2) Professional heating treatment and x-ray detection chamber for welding seam .

3) Vacuum system to prevent oil gas be back to reactor causing accident.

4) With professional thermometer , professiona pressure gauge and safety valve.

Environment friendly:

1) Dedusting system to prevent gas and dust from coal burning

2) The exhaust gas will be recycled for heating reactor ,no gas pollution

3) Well sealing on every junction parts to prevent gas leak,no smelly

Longer service life :Using Q345R special steel plate ,welding seam with auto welding an will get heating treatment and x-ray detection to extend the life of reactor to the most extend, and the life will 8 years.

Energy saving:1) Well sealing for heating system ,no gas leak and saving fuel.

2) The exhaust gas will be recycled for reactor heating.

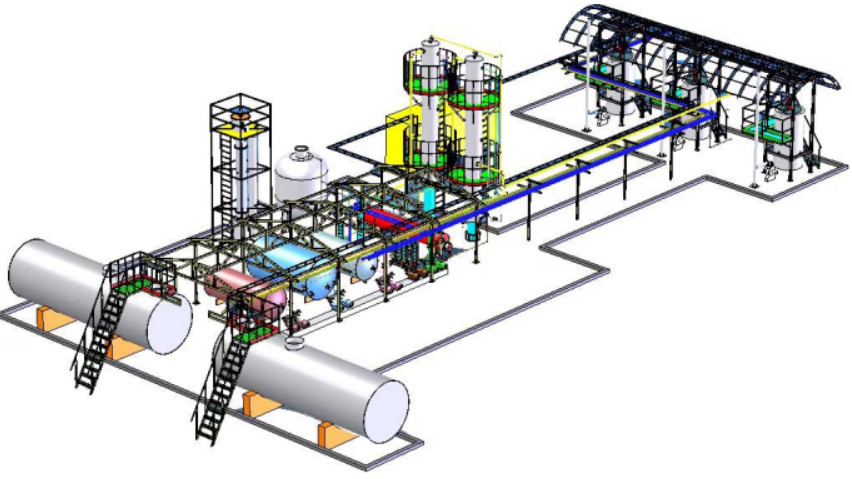

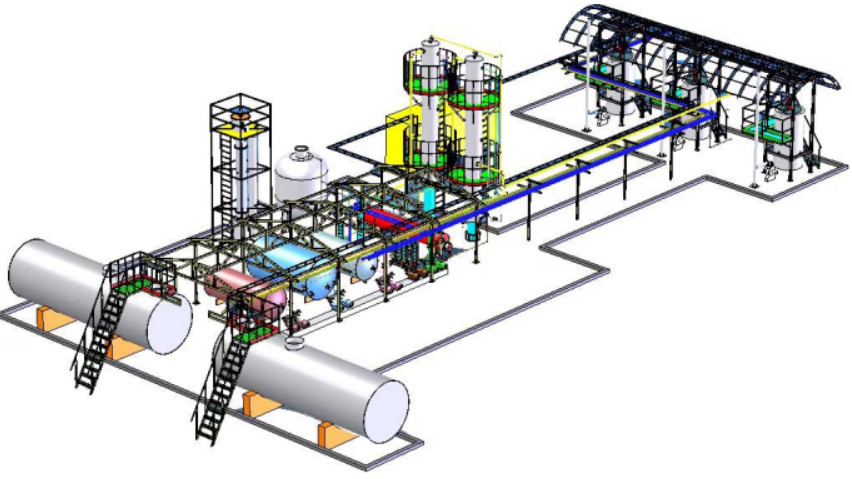

What is LD vegetable seed oil re-refining plant Looks Like?

Deodorization Tower

Refinery Plant

Installation in Bangladesh

vegetable seed oil re-refining plant adapt to many materials:

Packaging & Shipping

1. |

Ensure to timely provide complete sets of equipment and accessories. |

2. |

Ensure that one-time installation debugging acceptance. |

3. |

To provide high quality material with preferential price. palm oil press |

4. |

Priority to provide customer our new craftworks and products. |

5. |

Free training technological operator to ensure the trained staff can operation independently. |

6. |

In the installation process,we will appoint a installation supervision staff on the spot. |

7. |

we will offer an experienced project manager, organize a good installation team for the work of field installation debugging. |

8. |

After the equipment field assembly and installation, we will be also responsible for the single equipment debugging, online debugging and Feeding trial operation,to ensure that equipments can normal operate in full load conditions. We will provide all kinds of information and records according to the requirements of the bid. The qualified completion files will be provided to customers according to their requirements withinone month after acceptance. |

9. |

In the warranty period, all because of the quality of products has caused the damage or failure of equipment,suppliers will take the responsibility for the free repair and replacing spare part. Due to the damage caused by the customer,we only charge material costs for repair and replacement. After the receipt of customers notice,we will suggests the method to solve problem within six hours,or send specialist to the site to solve the problem within twenty four hours. |

Company Information

Our main business:

⢠10-500T/H oil material first cleaning,drying and storage section turn-key project.

⢠100-3000 T/D oil pretreatment, shelling and pre-press workshop turnkey project (soybean hot peeling, bean skin crushing; the soybean extrusion, high oil contained pre-press cake extrusion, and high oil contained embryos puffed; of direct puffed). Rice bran production line turn-key project.

⢠Leaching workshop turnkey project (Towline extractor, Rotocel extractor, loop type extractor, DTDC separated machine, the full negative pressure evaporation, paraffin wax recovery, leaching workshop degum, phospholipid concentrate).

⢠30-1000T/D oil continuous grade two or one physical (chemical) refining production line.

⢠10-600T/D sunflower oil, rice bran oil, corn germ oil dewaxing turn-key project

⢠10-200T/D Fatty acid esterification production cooking oil production line.

Workshop production capacity:

Any more questions or needs,please contact with me!!!

Shandong Leader Machinery Co.,Ltd. is one of the leading Manufacturers and Suppliers of 2016 LD company vegetable seed oil re-refining plant.Shandong Leader Machinery Co.,Ltd. manufacture 2016 LD company vegetable seed oil re-refining plant making machine using cutting-edge technology, Shandong Leader Machinery Co.,Ltd. have many kinds of Full Continuous Refining Line for you reference,such as 2016 LD company vegetable seed oil re-refining plant ,Shandong Leader Machinery Co.,Ltd. can meet your different requirement in Full Continuous Refining Line.Welcome to contact Shandong Leader Machinery Co.,Ltd.,contact name:Ms.Myra for a quotation

(Tel/whatsapp:0086-18363092712, Email:[email protected],Skype:leaderfoodmachine2).Welcome to send us your enquiry about capacity for 2016 LD company vegetable seed oil re-refining plant, inform us raw material you want to use for 2016 LD company vegetable seed oil re-refining plant,and specific requirements for 2016 LD company vegetable seed oil re-refining plant.Shandong Leader Machinery Co.,Ltd. will provide you best solution for your project about Full Continuous Refining Line.