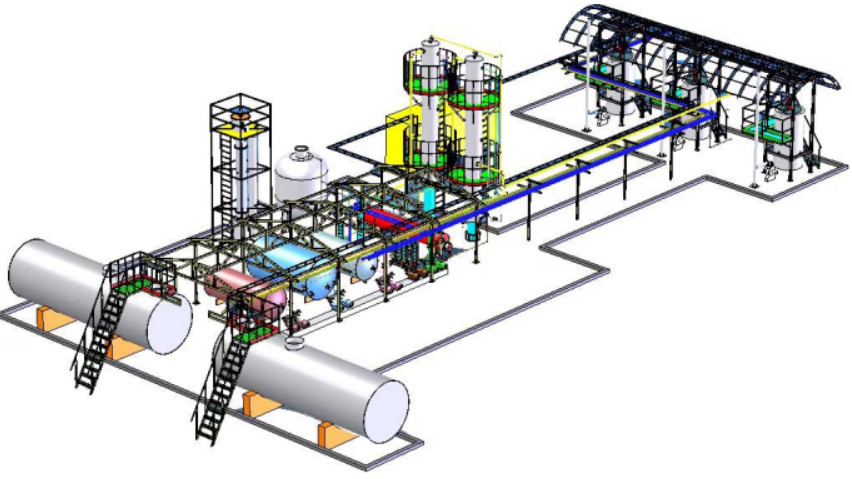

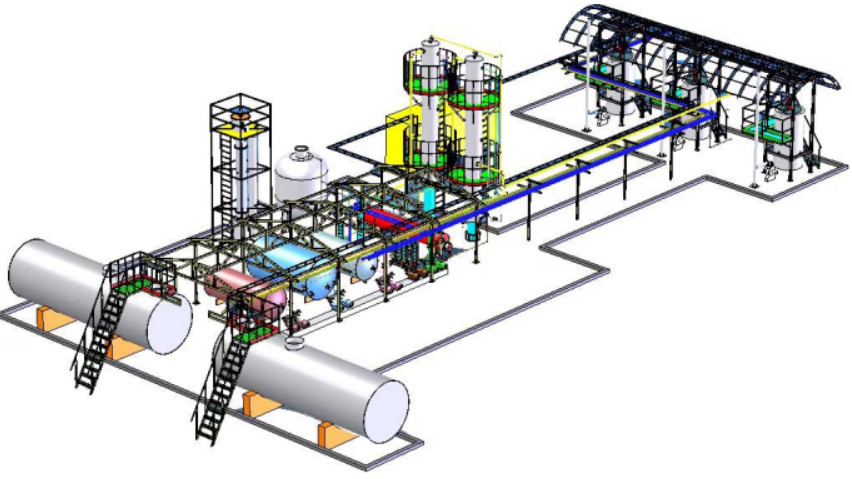

1. Description of Full Continuous Refining Line:

Palm oil machinery 10 tons one day is based on the difference of oil and the impurities in the physical and chemical properties, separate the grease and impurity by some technical ways ,in order to improve the oil edible,storage stability and safety process.Palm oil machinery 10 tons one day is divided into chemical refining and physical refining.The mini crude oil refinery we adopt suits different kinds of vegetable oil process.According to the raw materials and capacity , we can use batch, continuous, physical and chemical refining design. The product mini crude oil refinery of edible oil equipment can reach first to fourth grade. Guarantee the highest quality in lowest cost.

Capacity of Palm oil machinery 10 tons one day:5TPD-1000TPD

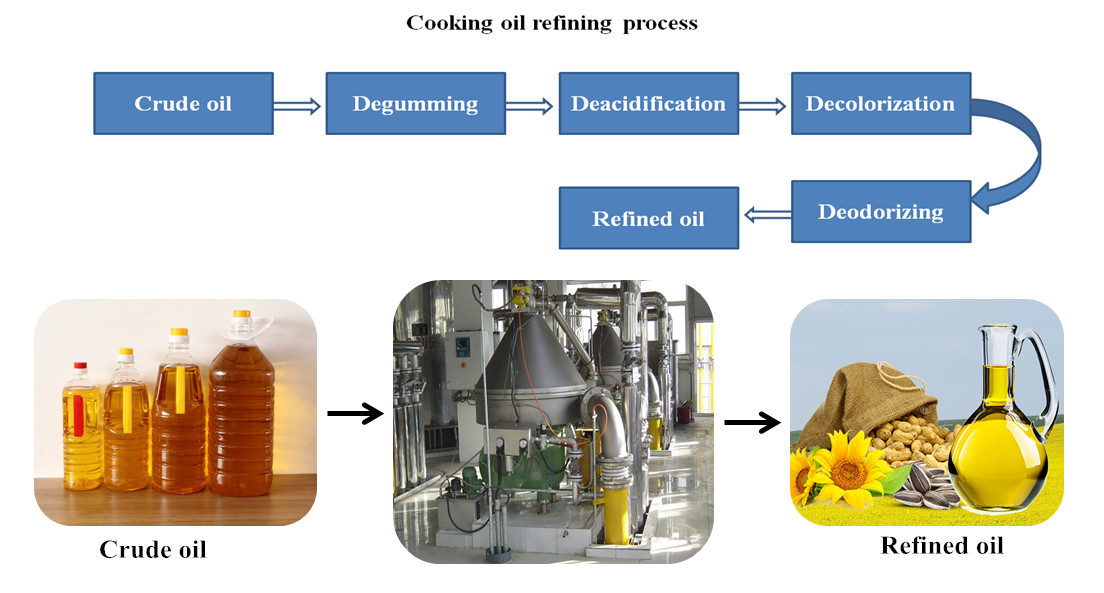

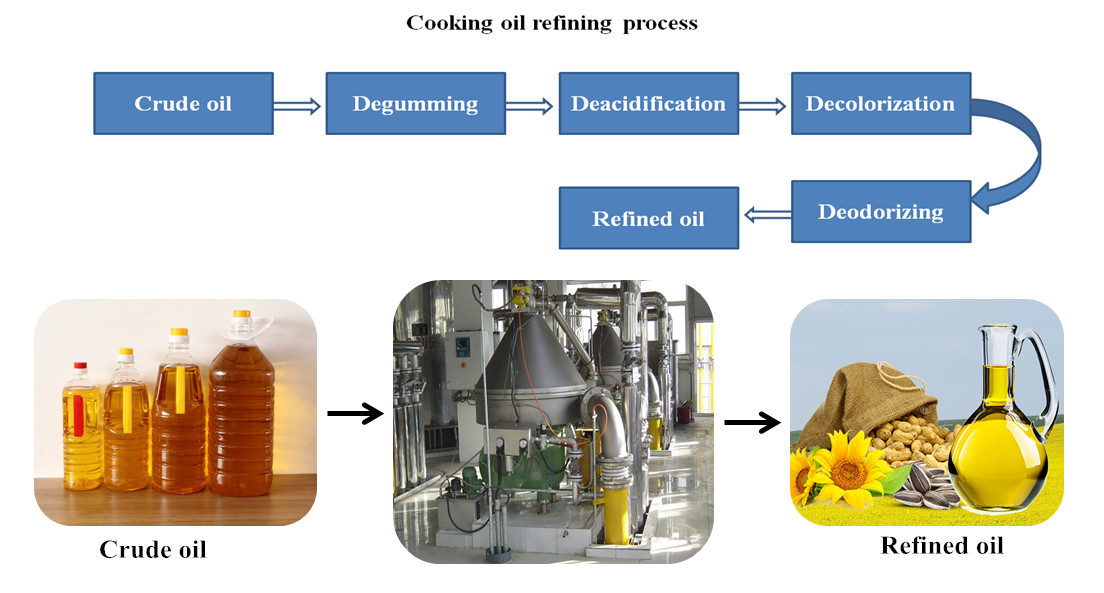

2.Full Continuous Refining Line process:

Main process of Palm oil machinery 10 tons one day:

**Hydration Deguming & Alkali Refining Deacidification Process

**Continuous Refining Decoloring Process

**Continuous Refining Deodorizing Process

**Automatic Control System of refined canola oil price equipment and so on

3.Advantages of Full Continuous Refining Line:

**The oil fully contacting with the decolorant can improve the decolorization efficiency and reduce the usage of decolorant.

**The continuous and uniform material flows of crude oil refinery will balance the decoloring time and avoid the recovery of grease oxidation and acid value.

**The special mixing structure of decoloring tower won't cause the material dead area, which can avoid the adsorbent sedimentation and pipe blockage.

**The continuous airtight efficient filtration equipment of crude oil refinery has realized the automation of cake discharge and reduced the labor intensity.

**The advanced drying technology of crude oil refinery can reduce the oil content in filter cake.

Palm oil machinery 10 tons one day

Palm fruit:

Palm oil processing line

Reception station of Palm oil machinery

Palm fruit oil mill Reception is used for loading the Fresh fruit bunch (FFB) to the palm fruit cage. It adopts hydraulic control system. According to our experience, some palm oil plants use concrete structure, but itâs not good for cleaning. Now we adopt steel material, fence structure. Some impurity will drop down to a conveyor, impurity will conveyed to outside, which is easier for cleaning.

Sterilizing station Palm oil machinery

Boiling and sterilizing fresh palm fruit bunches at high temperature( more than 145â). The bunches are airtight in sterilizer. The purpose of this station is to prevent enzymes from breaking down, so that FFA content of the fruit will not increase further. Besides, that also makes the fruits soft and wet, easy to get off bunches and be crashed.

For big scale palm plant, we suggest horizontal sterilizer, which deals with large quantity of raw material effectively in short time, but expensive and complex. If youâve a small mill, an vertical sterilizer is enough. It is economic and easy to operate.

Our sterilizer is produced according to the national safety requirements for pressure vessel.

Threshing station of Palm oil machinery

Palm fruit thresher in palm oil plant is used for separate empty fruit bunch and palm fruit.

According the palm oil mill capacity we can design the thresher capacity, usually we have a spare one, in case one of them not work.

Empty fruit bunch from thresher will be conveyed to outside, can be used as fertilizer in palm fruit plantation. Sterilized palm fruit will be convey to next station.

Thresher shaft uses once forging technology .The equipment is stronger and has longer life.

In the threshing station, we adopt steel structure, easy clean, easy operate, easy maintain.

Digester of palm oil machinery

There are rolling blades in the digester, which are driven by one motor on the top of the digester. The blades stir and crash palm fruits. Besides, we will fill the digester with indirect hot steam for heating and cooking. As a result, the fruit peel are broken off; fruit pulp become crashed and soft; fruit kernel is separated from pulp; pulp cell structure is destroyed under high temperature, making the oils and fats easier to get out, yielding much oil.

Press station of palm oil machinery

Pressing station in palm oil plant is include digester and oil presser.

Sterilized palm fruit from thresher conveyed to digester. There are blades in digester, blades will be rolling by motor which is on the top of digester. Palm fruit peel can be crushed by blades, besides we will fill the steam in digester for heating. Palm fruit pulp cell can be destroyed under the high temperature condition, after that we can get higher oil yield.

Clarification station of palm oil machinery

Using latest technology, on promise that guarantee oil quality, we try our best to reduce machine investment and oil loss.In actual production, it has been verified that using new technology can reduce oil loss blow 1.3%.

Crude oil tank of palm oil machinery

Our company

Customer visiting

Shipping

30TPD palm oil processing factory for our client

Certificate

Feel freely to contact me

Shandong Leader Machinery Co.,Ltd. is one of the leading Manufacturers and Suppliers of Palm oil machinery 10 tons one day.Shandong Leader Machinery Co.,Ltd. manufacture Palm oil machinery 10 tons one day making machine using cutting-edge technology, Shandong Leader Machinery Co.,Ltd. have many kinds of Full Continuous Refining Line for you reference,such as Palm oil machinery 10 tons one day ,Shandong Leader Machinery Co.,Ltd. can meet your different requirement in Full Continuous Refining Line.Welcome to contact Shandong Leader Machinery Co.,Ltd.,contact name:Ms.Myra for a quotation

(Tel/whatsapp:0086-18363092712, Email:[email protected],Skype:leaderfoodmachine2).Welcome to send us your enquiry about capacity for Palm oil machinery 10 tons one day, inform us raw material you want to use for Palm oil machinery 10 tons one day,and specific requirements for Palm oil machinery 10 tons one day.Shandong Leader Machinery Co.,Ltd. will provide you best solution for your project about Full Continuous Refining Line.