Industrial peanut butter machine/ peanuts butter production line produced and supplied by Shandong Microwave Machinery Co.,Ltd.

Industrial peanut butter machine/ peanuts butter production line ---Roasting:

Peanut Butter Production Line working temperature is 200-210 oC, 20-30minutes.use batch roaster will bake some delicious smells.

Industrial peanut butter machine/ peanuts butter production line ---Cooling: Peanut will be send cooling belt to cool.

Peanut Butter Production Line ---Peeling:

put the roasted peanuts into Industrial peanut butter machine/ peanuts butter production line to take off the red skin, the double rollers will frication the red skin, the simple cyclone system of Peanut Butter Production Line will suck the red skins, most of them will be put in half-piece, then fall to the selecting conveyor, the over-roasted and un-blanched peanut kernel is picked up by manual or mechanical Peanut Butter Production Line. (Industrial peanut butter machine/ peanuts butter production line is matched with manual type conveyor in the quotation)

Industrial peanut butter machine/ peanuts butter production line --Primary grinding: Using steel grinder to make the first grinding;

Peanut Butter Production Line --Second grinding:

Using colloid grinder to make the second grinding, the fineness of grinding is controlled below 7um, temperature of grinding is controlled below 68C.

Industrial peanut butter machine/ peanuts butter production line ---Blending: make the butter more homogeneous

Peanut Butter Production Line ---Cooling:

the butter through second grinding should be cooled immediately. The temperature of Industrial peanut butter machine/ peanuts butter production line should go down 45C.

Industrial peanut butter machine/ peanuts butter production line --Degasser : Take out the air from peanut butter.

Peanut Butter Production Line --Storage tank:

settling down in the storage tank till the temperature drop to air temperature.

Peanut Butter Production Line --packing

by the filling machine, the finished peanut butter is packed into 200g/500g/1000g bottle

Specifications

Industrial peanut butter machine/ peanuts butter production line400kg/hr

High automatic

450kg/hr peanut butter production equipment Peanut butter production line/ peanut butter makin machine (If you want other capacity, pls let me know)

peanut butter making machine ,Peanut butter making machine, peanut butter production line, peanut butter processing line

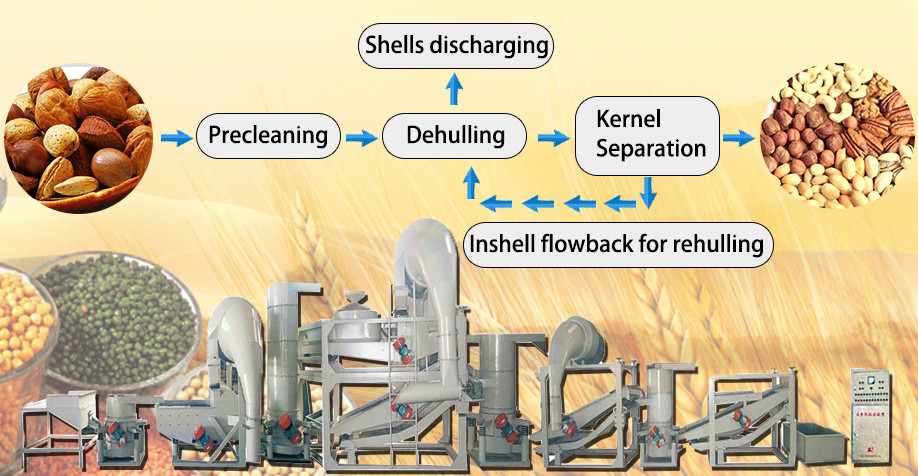

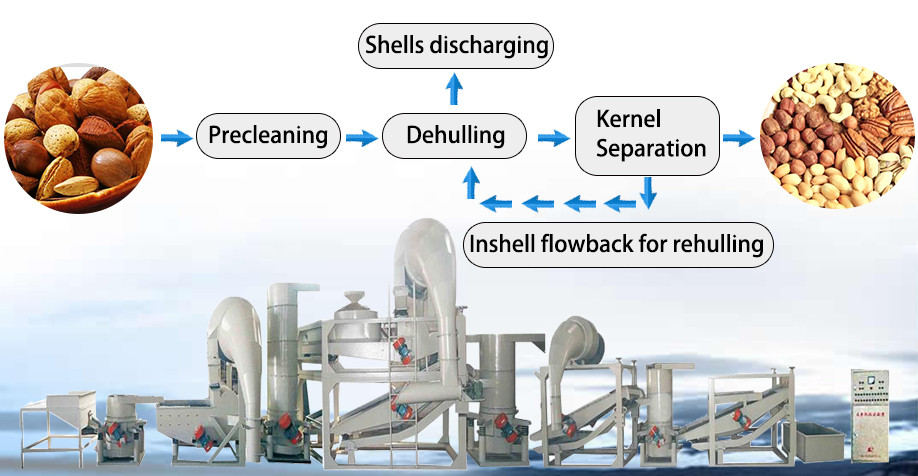

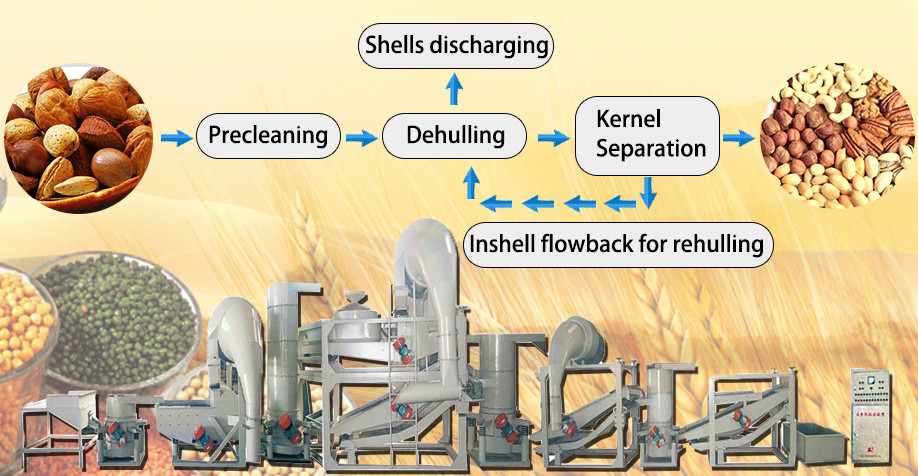

Flow chart of peanut butter production line:

Roasting---Cooling--Peeling--Selecting --Milling--Mixing--Cooling--de-gasing-- filling

peanut butter Production line

Industrial peanut butter machine ---Roasting

batch roaster’s working temperature is 200-210 ºC, 20-30minutes.use batch roaster will bake some delicious smells.

Industrial peanut butter machine ---Cooling: Peanut will be send cooling belt to cool.

Industrial peanut butter machine --Peeling:

put the roasted peanuts into peeler to take off the red skin, the double rollers will frication the red skin, the simple cyclone system will suck the red skins, most of them will be put in half-piece, then fall to the selecting conveyor, the over-roasted and un-blanched peanut kernel is picked up by manual or mechanical. (It is matched with manual type conveyor in the quotation)

Industrial peanut butter machine ---Primary grinding:

Using steel grinder to make the first grinding;

Industrial peanut butter machine ---Second grinding:

Using colloid grinder to make the second grinding, the fineness of grinding is controlled below 7um, temperature of grinding is controlled below 68C.

Industrial peanut butter machine --Mixing: make the butter more homogeneous

Industrial peanut butter machine ---Cooling:

the butter through second grinding should be cooled immediately. The temperature should go down 45C.

Industrial peanut butter machine ---Degasser : Take out the air from peanut butter.

Industrial peanut butter machine --Storage tank:

settling down in the storage tank till the temperature drop to air temperature.

Industrial peanut butter machine ----Packing:

by the filling machine, the finished peanut butter is packed into 200g/500g/1000g bottle

ABOUT US

ShandongLD Food Machinery Manufacturing Co., Ltd., established in 1993 and situated in Jinan City of Shandong Province, Shandong Province with a registered capital of 2,000,000 RMB and an area of 9,800 square meters, is a professional food machinery manufacturing company integrated with R&D, professional manufacturing, direct sales and after sales service. We have taken lead in issuing and passing Shandong Business Product Quality Standard and have been smoothly certified to ISO9001:2008 International Quality Management System, CE safety certification for exporting to European Union, BV certification, the third party certification. Now we have successfully gained trademark.

WELCOME TO VISIST US---- peanut butter production equipment manufacturer

Contact us:

Carrie-Sales manager

Shandong Microwave Machinery Co.,Ltd.

Web: www.epier.com

Email: [email protected]

Skype:leaderfoodmachine10

Moblie:0086-15020017267(also WhatsApp)

Shandong Microwave Machinery Co.,Ltd.is a Peanut Butter Production Line factory specializing in the production of Industrial peanut butter machine/ peanuts butter production line, scientific research,manufacturing,installation, commissioning.Shandong Microwave Machinery Co.,Ltd.can provide Peanut Butter Production Linecustomers with design and services of 1-2000 tons Industrial peanut butter machine/ peanuts butter production line. Shandong Microwave Machinery Co.,Ltd. have finished hundreds of successful projects Peanut Butter Production Lineover the years: peanut oil, soybean oil, rapeseed oil, cottonseed oil, sunflower oil, sesame oil, animal oil,grape seed oil, acer truncatum oil, peony seed oil, walnut oil, hemp seed oil, pine oil, tea seed oil, papaya oil, milk thistle seed, and other special type Peanut Butter Production Lineoil. Shandong Microwave Machinery Co.,Ltd. have independent import and export department. Shandong Microwave Machinery Co.,Ltd. Peanut Butter Production Lineequipment has been successfully exported to more than ten countries: Russia, Australia, India, Afghanistan, Cameroon,and so on.