Shandong Leader Machinery Co.,ltd. have engaged in Oil Refinery Equipment and Microwave Equipment since1997 in China,with 20 years` experience and 80 engineers,, scientific research, manufacturing, installation, commissioning.We can provide customers with design and services of 1-2000 tons oil equipment.factory occupied area is over 100,000 square meters,more than 3200 customers all around the world, we greatly hope to have the opportunity to serve you.

Product Description:

According to customers on the type of oil, daily processing volume, oil standards and other conditions of the requirements of processing customization, size, refining the number of cans, product prices are different.

High Efficiency Spices Dryer Machine/Chicken Essence Microwave Drying Machine/Sterilization

Application:

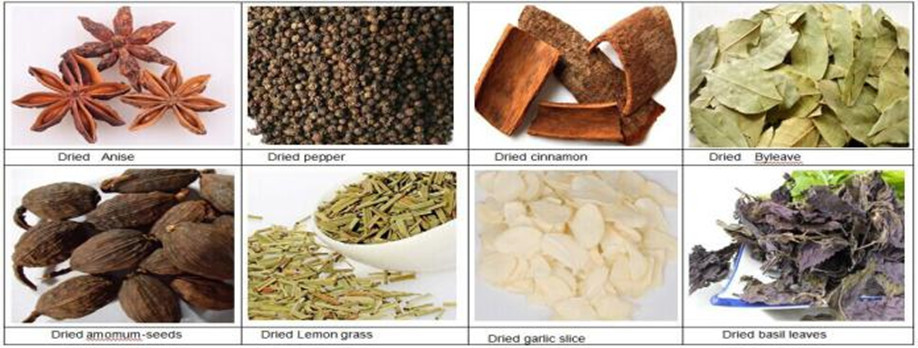

Microwave Dryer sterilization equipment is mainly used for all kinds of spices dry sterilization,

such as powder chili powder curry powder row bone custard powder, garlic powder, chili powder

Five-spice powder etc.

Microwave dryer sterilization equipment features:

1. Microwave drying machine to dry out the chicken is more delicious. Because the drying

efficiency is very high, to ensure the loss of nutrients not chicken essence inside.

2. time is short, fast. The sterilization effect of various materials in commonly 3 to 5 minutes.

3.low temperature sterilization keep nutrients and traditional flavor, general sterilization

temperature from 75 to 80 degrees Celsius

4. save energy and electricity can generally be 30% - 50%.

5.even completely, because the microwave penetration has, in the food whole processing, surface

and internal at the same time by role, so the sterilizing thoroughly.

6. easy to control, convenient operation and microwave power can be adjusted, speed adjustable

from scratch, convenient for operation.

7. simple equipment, advanced technology, microwave devices do not need to boiler, complicated

pipeline system, coal yard and transport vehicles, as long as have the water and electricity basic

conditions.

8.improve working conditions, the save area

Packing & shipping

1. Delivery Term: FOB / CFR / CIF

2. Delivery time: 20 work days after having received payment

3. Package: wooden cases(fully meets with export package requirements)

4. Payment Terms: 50% deposit by T/T,balance 50% paid by T/T before shipment.

5. Transportion : By vessel

Our service

1. Commissioning Service:

The price doesn't include install and test cost(When we delivery machine,we will provide detailed information,includes how to install,you can install by yourself).OR 1~2 technican go to your warehouse for 7~10days and the cost will be at buyer’s account,one person is USD 70/day.

2. Warranty:

While deliverying machine,we will provide 2 sets spare parts freely.For the whole equipment,warranty is 12 months,within 12 months,if have equipment quality problems,we will provide accessories freely. After the expiration of the warranty period,if have spare parts problem,we only receive the cost of required replacement parts.We commit we will provide free technical support of equipment all whole life.

3. Pre-shipment Inspection:

supplier should make trial run for the whole packing assemble at supplier’s factory

before shipment .

4. We reserve the right of technology improvement.

The specification of factory direct sales quality microwave drying machine:

1)Machine material: food-grade SUS304 stainless steel

2)Energy-saving more than 30%

3)High production efficiency

4)Improve product quality: nice color and good taste

5)Safety and easy clear.

6)Improve working conditions: PLC touch screen control, automatically operation

High Efficiency Spices Dryer Machine/Chicken Essence Microwave Drying Machine/Sterilization

High Efficiency Spices Dryer Machine/Chicken Essence Microwave Drying Machine/Sterilization main performance characteristics

When picking fresh leaves without traditional filming for the pre cooling can be directly into the microwave drying equipment.When High Efficiency Spices Dryer Machine/Chicken Essence Microwave Drying Machine/Sterilization and the new technology of tea processing his time than traditional production shorten the above four small, use labor per shift just 2 people, improve labor efficiency is 400%, and greatly reduce the labor intensity of the workers.

Advanced microwave, according to the requirements of the tea leaves at different stages dehydration rate to filming for the level with high efficiency.

AAA1

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: [email protected]