Shandong Leader Machinery Co.,ltd. have engaged in Oil Refinery Equipment and Microwave Equipment since1997 in China,with 20 years` experience and 80 engineers,, scientific research, manufacturing, installation, commissioning.We can provide customers with design and services of 1-2000 tons oil equipment.factory occupied area is over 100,000 square meters,more than 3200 customers all around the world, we greatly hope to have the opportunity to serve you.

Product Description:

According to customers on the type of oil, daily processing volume, oil standards and other conditions of the requirements of processing customization, size, refining the number of cans, product prices are different.

Industrial Tunnel Continuous Conveyor Belt Type Microwave Herbs Drying Sterilization Machine/Dryer&Sterilizer Machine/Herb Dryer Features:

1 tunnel conveyor belt herb microwave leaves dryer sterilizer

2 fast drying(4~5minutes)

3 tunnel belt type,work continuously

4 save energy/efficient

5 easy to control

Product Description

1.Application of herb drying machine:

1. chemical material,medicine tablet or pill,such as watered pills,water-honey bolus,honeyed bolus,condensed pill and Tibetan pill,etc.

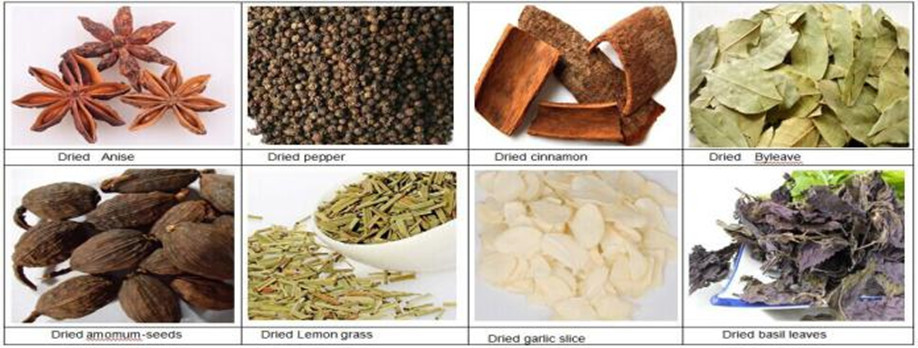

2.all kinds of teas,herbs, flowers, green leaves,etc.

3.various dried meat, like beef, pork, chicken,duck, fish etc

4. powder for various material,such as spices, other food additives

5. agricultural products,such as china date,nuts,s,peanut,etc

6.snakefood, such as melon seeds,photo chips,etc.

2.Instruction of herb dryer:

(1) High efficiency: compared with general drying technologies,it can increase work effciency at least four times above.

(2) Even heating:As micorwave heating heats up the inside and outside of materials at the same time.Temperature difference between the inside and outside of materials is uniform,Thus,there is no question of apperaring heating variance of inside and outside which general heating will happen.Drying quality is greatly improved.

(3) Easy to control:it is convenient for continuous production,and it realizes automatization.Based on its characteristics of quick arrangement of microwave power and no inertia, it is easy to instant control,as well as arrangement and determination of process parameters.

(4) Small size.There is monitour installed in the interior,which can observe all courses of drying.

(5) Besides,microwave equipment owns sterilization and disinfection effects,whcih can make the processed products safe and healthy,as well as long quality guaranteed period.

(6) By processing dehydrated vegetables,the comparative results of different drying equipment’ processing property,economic benefit,product quality etc.

3.Technical parameters of herb drying equipment:

|

SHANDONG Microwave TRADE CO., LTD. Shandong,China. | |||||

| Reference Technical Parameters | |||||

| Model | Rated input power(KVA) | Microwave output power(KW) | Expected dehydration(kg/h) | Expected sherilization capacity(kg/h) | Size L*W*H(mm) |

| JN-12 | 16.8 | 12 | 12~17 | 150~200 | 7200*840*2050 |

| JN-15 | 21 | 15 | 15~21 | 200~280 | 8300*840*2050 |

| JN-20 | 28 | 20 | 20~28 | 280~350 | 9400*840*2050 |

| JN-30 | 42 | 30 | 30~42 | 400~500 | 10500*1440*1750 |

| JN-40 | 56 | 40 | 40~56 | 550~700 | 10500*1440*1750 |

| JN-50 | 70 | 50 | 50~55 | 700~850 | 11600*1440*1750 |

| JN-60 | 84 | 60 | 60~84 | 850~1000 | 12700*1440*1750 |

| JN-70 | 98 | 70 | 70~~98 | 1000~1100 | 13800*1440*1750 |

| JN-80 | 112 | 80 | 80~112 | 1200~1400 | 14900*1665*1750 |

| JN-100 | 140 | 100 | 100~140 | 1400~1600 | 14900*1665*1750 |

| JN-120 | 168 | 120 | 120~168 | 1680~2000 | 17100*1665*1750 |

| JN-150 | 210 | 150 | 150~210 | 2100~2500 | 20400*1750*1750 |

| NOTE:These dates are only for your reference.We can design according to your requirements.We reserve the improvement of technology! | |||||

4.Reference pictures of herb leaves dryer:

Packaging & Shipping

1. Delivery Term: FOB / CFR / CIF

2. Delivery time: 20 work days after having received payment

3. Package: wooden cases(fully meets with export package requirements)

4. Payment Terms: 50% deposit by T/T,balance 50% paid by T/T before shipment.

5. Transportion : By vessel

Our Services

1. Commissioning Service:

The price doesn't include install and test cost(When we delivery machine,we will provide detailed information,includes how to install,you can install by yourself).OR 1~2 technican go to your warehouse for 7~10 days and the cost will be at buyer’s account,one person is USD 70/day.

2. Warranty:

While deliverying machine,we will provide 2 sets spare parts freely.For the whole equipment,warranty is 12 months,within 12 months,if have equipment quality problems,we will provide accessories freely. After the expiration of the warranty period,if have spare parts problem,we only receive the cost of required replacement parts.We commit we will provide free technical support of equipment all whole life.

3. Pre-shipment Inspection:

supplier should make trial run for the whole packing assemble at supplier’s factory

before shipment .

4. We reserve the right of technology improvement.

If you are interested in our microwave equipment,please feel free to contact me!

30KW Tunnel Conveyor Belt Type Industrial Microwave Herb Dryer is suitable for the normal pressure/micropressure/water decoction/warm maceration/hot reflux forced circulation/permeation extraction & concentration,organic solvent recovery concentration and other processes in Chinese traditional medicine, health products, biological, pharmaceutical, cosmetic and food industries.This is the ideal equipment for Shandong Leader Machinery Co.,ltd., research institutes,research and development departments and laboratories of enterprises and institutions,and many varieties,small batch production of pharmaceutical plant.

AAA1

30KW Tunnel Conveyor Belt Type Industrial Microwave Herb Dryer future

1.Fast heating speed: directly heat on the internal and external of material at the same time, do not need to preheat. While there must be a preheating process in the traditional production.

2. Heating evenly: microwave drying is completed through electromagnetic waves produced by magnetron.The internal and external of material will be heated at the same time .

3. Less nutrition loss: material just stay in the microwave heating box for a short time, and do not need air and steam to conduct heat, therefore can maximize keep nutrients in the material.

4. Sterilization and alcoholization:The microwave drying equipment also have sterilizing and alcoholizing function.

5. Reduce the labor intensity, improve work efficiency

AAA2

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: [email protected]