Shandong Leader Machinery Co.,ltd. have engaged in Oil Refinery Equipment and Microwave Equipment since1997 in China,with 20 years` experience and 80 engineers,, scientific research, manufacturing, installation, commissioning.We can provide customers with design and services of 1-2000 tons oil equipment.factory occupied area is over 100,000 square meters,more than 3200 customers all around the world, we greatly hope to have the opportunity to serve you.

Product Description:

According to customers on the type of oil, daily processing volume, oil standards and other conditions of the requirements of processing customization, size, refining the number of cans, product prices are different.

2015 hot sel Microwave dryer/microwave drying sterilization for almond equipment

Brief introduction

1. High energy conversion efficiency, fast heating, low energy loss

2. Advanced craft, easy to control, fast heating, wonderful baking and puffing effect

3. Microwave baking and puffing simultaneously, along with bactericidal effect

4. Low-temperature baking and puffing, less nutrition loss, puffing without oil, better for health.

Application

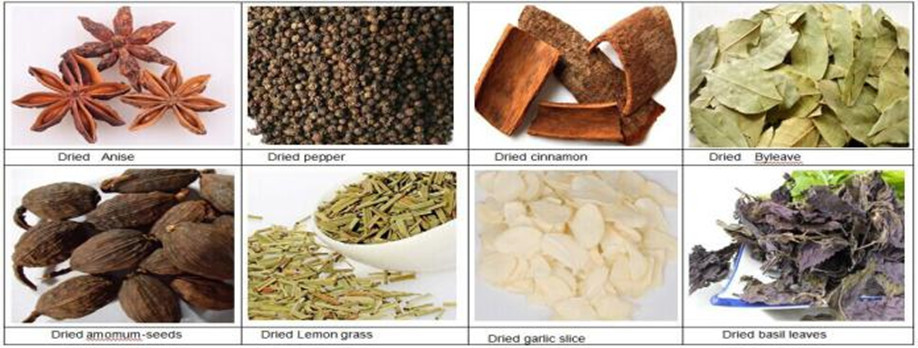

Microwave industrial tunnel baking&puffing equipment are widely used in the peanut, sesame seeds, wheat,

melon seeds, sunflower seeds, peanuts, corn, soybeans, walnuts, almonds, chestnuts, pistachios, cashews,

filbert and dried fruit etc; and for leisure food, pachyrhizus chips, potato chips, dried shrimps, fish maw and so

on. Compared with the traditional production methods, microwave baked foods are crispy and delicious,

products particle puffed full, natural color, beautiful appearance, and has insecticidal sterilization effect.

Features

1. Energy conversion efficiency high, fast heating.

Microwave oven itself, but microwave energy fever, make the material through materials within polarity produced molecular friction between internal heat. Make the liquid inside processed materials instantaneous warming vaporization, boosting inflation; And depend on gas expansion force make component of macromolecule substance, and become a structural degeneration areolar tissue structure characteristics, finalize the design of microporous shape more than substance.

2. when microwave baking ,sterilization effect at the same time.

Microwave sterilization is in the microwave heating and the dual role of non-thermal effect under the temperature sterilization, compared with conventional in lower temperature and very short time get satisfactory antiseptic effect. General sterilizing temperature around in 80 °C, the processing time in 3 ~ 5 minutes, and to the maximum maintain its nutrients.

3.The operation is convenient.

Microwave power and conveyor belt speed can adjust arbitrary

, both thermal inertia, but do not exist, simple, easy to open namely stop control. Improve the production environment. Microwave equipment nirvikalpa radiation, no dust, no noise, no pollution, easy to realize the food hygiene inspection standard.

4. Puffed effect is obvious.

Microwave fast heating effect, make the material internal water molecules, achieve rapid vaporization ,reach to the puffed purpose.

5. Low temperature sterilization, nutrition loss less.

Microwave sterilization is in the microwave heating and the dual role of non-thermal effect under the temperature sterilization, compared with conventional in lower temperature and very short time get satisfactory antiseptic effect. General sterilizing temperature around in 80 °C, the processing time in 3 ~ 5 minutes, and to the maximum maintain its nutrients. The reserves of vitamin C conventional heat treatment fruits and vegetables is 46% ~ 50%, microwave, can reach 60 ~ 90; Keep to vitamin A conventional heat treatment is 58 percent, and microwave treatment is to 84%, and would not affect the original flavor, is the fruit and vegetable food processing, obtain the good means green food.

Microwave heating principle

Microwave is a sort of electromagnetic wave which frequency is 300MHz to 300GHz .The water

molecule in medium materials is polar molecule,under the effect of the rapid change of electro

magnetic field,its polarity orientation will alter with the changes of the external electric field with the

high-speed,causing the movement and friction of molecule.

So that the microwave field energy can be converted to heat energy in medium to rise the temperature

of materials.accomplishing heating ,puffing and a series of physical and chemical processes , and so

microwave heating is achieved.

Technical parameter

Power supply |

380V±10% 50HZ±1% three-phase five-wire |

|

Microwave Output Frequency

|

2450±50MHz |

Microwave input apparent power |

112KVA |

Microwave output power |

80KW |

Microwave power adjustment range |

0-80KW(adjustable) |

Ambient temperature |

-5-40°C |

Relative humidity |

80%, Surrounding environment:no corrosive gas, conductive dust and explosive gas |

Overall dimension(L*W*H) |

15200*1440*1750 mm |

Transmission speed |

0-10m/min(adjustable) |

Height of the inlet and outlet |

60 mm |

Microwave leak |

accord with a country GB10436-89 standards( |

Equipment safety |

accord with GB-5226Electrical safety standard accord with a country GB16798-1997 Food machinery health security index |

2015 hot sel Microwave dryer/microwave drying sterilization for almond equipment

Picture

If you are interested in our microwave drying and sterilization roasting machine, please feel free to contact to me.

Welcome to enquiry!

2015 hot sel Microwave dryer/microwave drying sterilization for almond equipment is suitable for the normal pressure/micropressure/water decoction/warm maceration/hot reflux forced circulation/permeation extraction & concentration,organic solvent recovery concentration and other processes in Chinese traditional medicine, health products, biological, pharmaceutical, cosmetic and food industries.This is the ideal equipment for Shandong Leader Machinery Co.,ltd., research institutes,research and development departments and laboratories of enterprises and institutions,and many varieties,small batch production of pharmaceutical plant.

AAA1

2015 hot sel Microwave dryer/microwave drying sterilization for almond equipment future

1.Fast heating speed: directly heat on the internal and external of material at the same time, do not need to preheat. While there must be a preheating process in the traditional production.

2. Heating evenly: microwave drying is completed through electromagnetic waves produced by magnetron.The internal and external of material will be heated at the same time .

3. Less nutrition loss: material just stay in the microwave heating box for a short time, and do not need air and steam to conduct heat, therefore can maximize keep nutrients in the material.

4. Sterilization and alcoholization:The microwave drying equipment also have sterilizing and alcoholizing function.

5. Reduce the labor intensity, improve work efficiency

AAA2

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: [email protected]