Introduction of Automatic weighting and packing machine:

1>. Automatic weighting and packing machine have main ten parts: Reception Station,Sterilizer,Threshing,Press,Clarification, Kernel Recover, power station, boiler station, water treatment plant, oil storage tank.

2>. Shandong Leader Machinery Co.,Ltd. use the Fresh Fruit Bunch, because the palm fruit rancidity is very fast, if the rancidity will be influence the palm crude oil acid value, if the acid value is very high, the refining efficiency will drop.

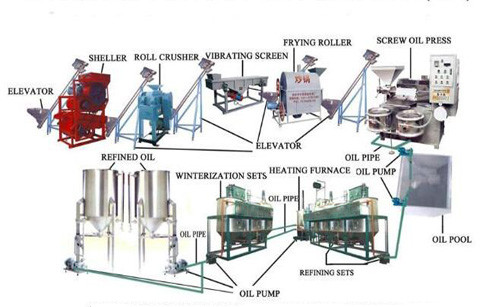

Working principle of Auxiliary Machine For Oil Press:

1. Transferred by the triangle belt, the electromotor drives the spiral shaft.

2. Oil plants being carried toward to the end of the machine by rotating squeeze spirals.

3. With the space between spirals and loops becoming smaller,the pressure in the chest is bigger.

4. During this process, oil plants are smashed and the tissue cells are destroyed, then oil is separated from oil plants.

5. After extracted, oil plants turns to be cakes containing low oil and is discharged in thin slices from the end.

Noodle packing machine automatic weighting and packing machine

Introduction

Automatic weighting and packing machine

The equipment consists of an automatic weighing, an automatic feeding machine, a combination of automatic packaging machines for vermicelli, automatic packaging plastic composite film type.

Features

1.The reasonable design, stable performance.

2.Automatic bag, sealing, printing survival date

3.Automatic weighing.

Specification

| Model | GLSM-450 |

| Packing weight | 200-1000g |

| Capacity | 15-25bags/min |

| Voltage | 220V,50Hz,1phase |

| Weight | 1000kg |

| Dimension | 3*3.5*1.7m |

Detailed technical data

Working Object: Elongated noodles, pasta

Noodle length: (180 ~ 240mm) ñ 5.0mm

Measurement methods: touch screen control two metering

Measurement range: 200 ~ 1000g

Measurement value setting: Digital input

Measurement value display: accurate to 0.1g

Measurement accuracy: 200 ~ 1000g, ñ 3.0g or less 96%;

Measurement speed and accuracy:

Noodle bar quality and varies the amount of packaging and differences.

200-300gâ¤28 beats / min, ñ 1.0g 97% or less;

300-500gâ¤25 beats / min, ñ 2.0g 96% or less;

500-1000gâ¤17 beats / min, ñ 3.0g 96% or less;

Any questions about automatic noodle weighting and packing machine,please contact Nancy freely.