Introduction of waste tire crumb processing line with resonable price:

1>. waste tire crumb processing line with resonable price have main ten parts: Reception Station,Sterilizer,Threshing,Press,Clarification, Kernel Recover, power station, boiler station, water treatment plant, oil storage tank.

2>. Shandong Leader Machinery Co.,Ltd. use the Fresh Fruit Bunch, because the palm fruit rancidity is very fast, if the rancidity will be influence the palm crude oil acid value, if the acid value is very high, the refining efficiency will drop.

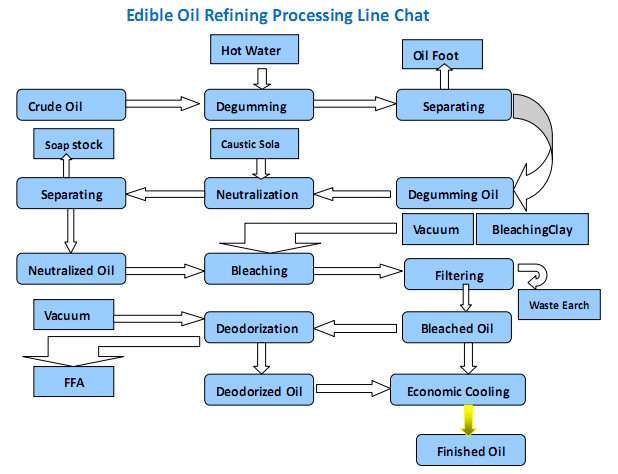

Working principle of Auxiliary Machine For Oil Press:

1. Transferred by the triangle belt, the electromotor drives the spiral shaft.

2. Oil plants being carried toward to the end of the machine by rotating squeeze spirals.

3. With the space between spirals and loops becoming smaller,the pressure in the chest is bigger.

4. During this process, oil plants are smashed and the tissue cells are destroyed, then oil is separated from oil plants.

5. After extracted, oil plants turns to be cakes containing low oil and is discharged in thin slices from the end.

Waste Tire Crumb Processing Line

1. raw material waste tire or rubber

2. output powder 30-40 mesh

3. whole line 4 person

4.simple and easy operation

Waste Tyre Powder Processing Flow Chart

Waste tyreâÂÂring cutter âÂÂstrip cutter âÂÂdice cutterâÂÂcrushing--- filtering--magnetic screeningâÂÂrubber powder.

Detailed Product Description

Waste tyre shreddering and recycling machine is mainly used for crushing waste tires into rubber powder for reuse.

Processing method:

Physic mechanical crushing method at normal temperature of waste tyre:nochemical raw material is required,no waste gas,washte water and soot are discharged, and the cooling water of the equipment is reused,no emission,equipment noise is within the range specified by the country,fineness of rubber powder produced by it is adjustable(10 meshes to 30 meshes),take waste tyre as example,the process is as follows:breaking down,crushing,filtering,magnetic separating,grin-ding,then the finished products are produced.

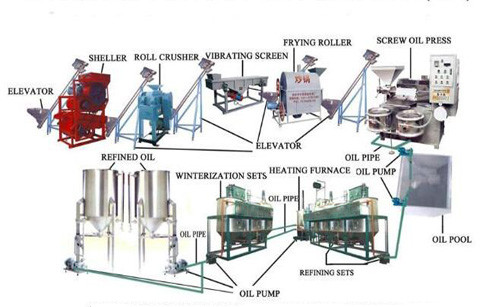

Pictures of the Machine

More information, feel free to contact me