Brief introduction of Small Paddy Corn Grain Drying Machine in Shandong Microwave Machinery Co.,Ltd.

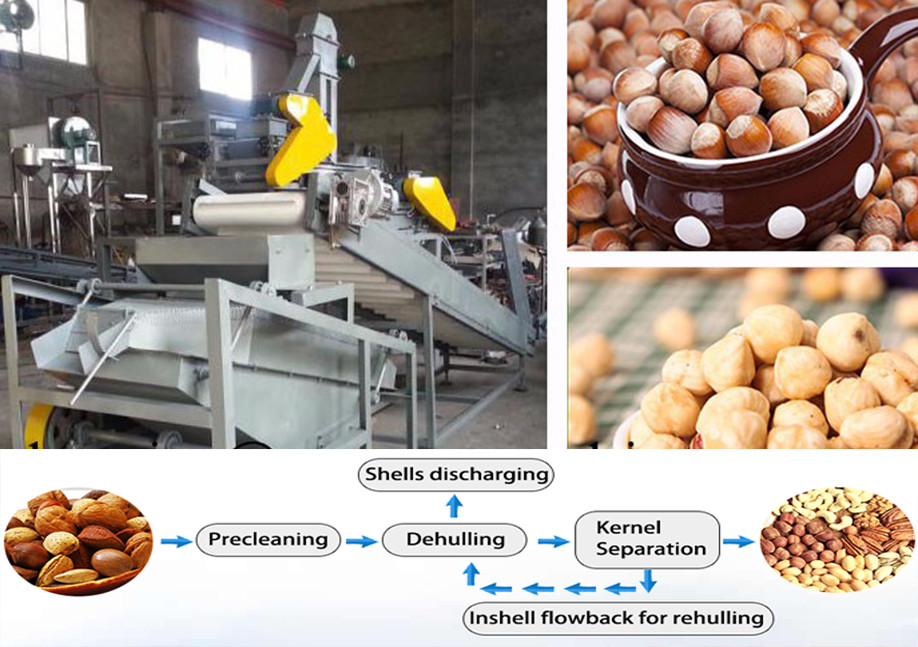

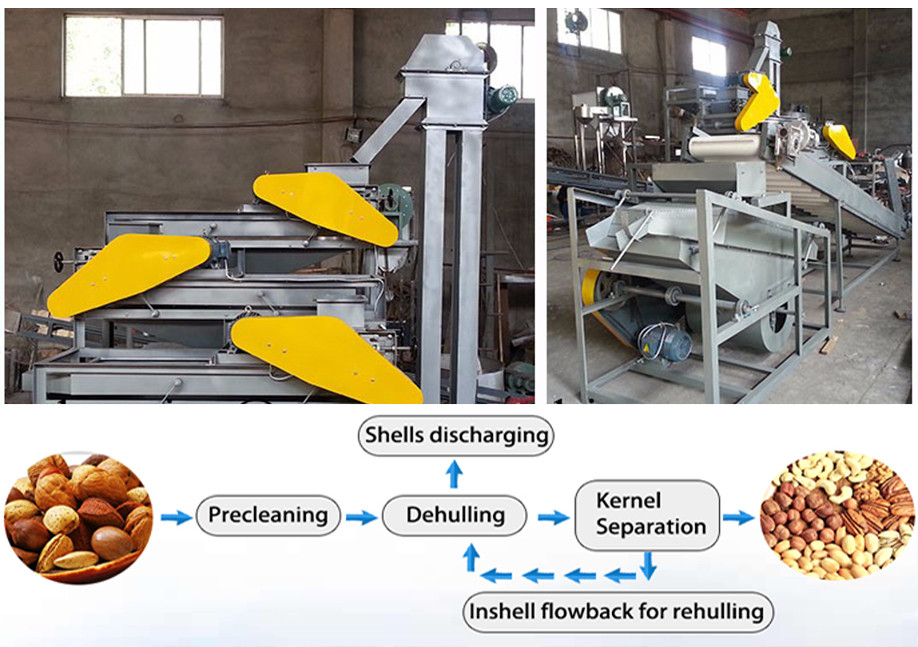

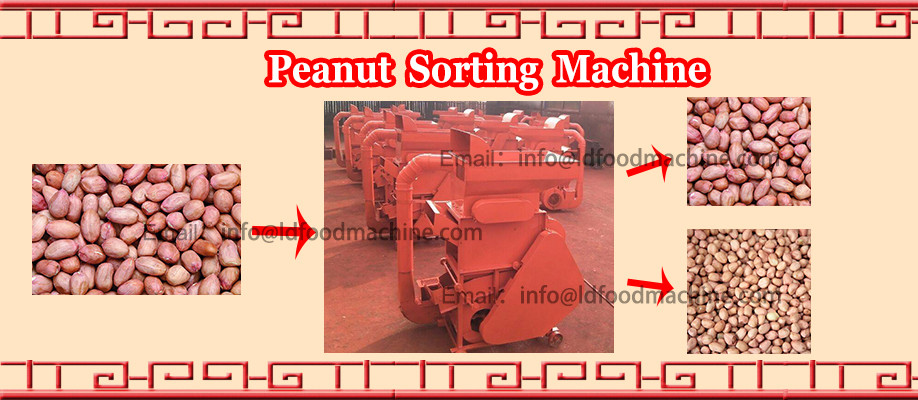

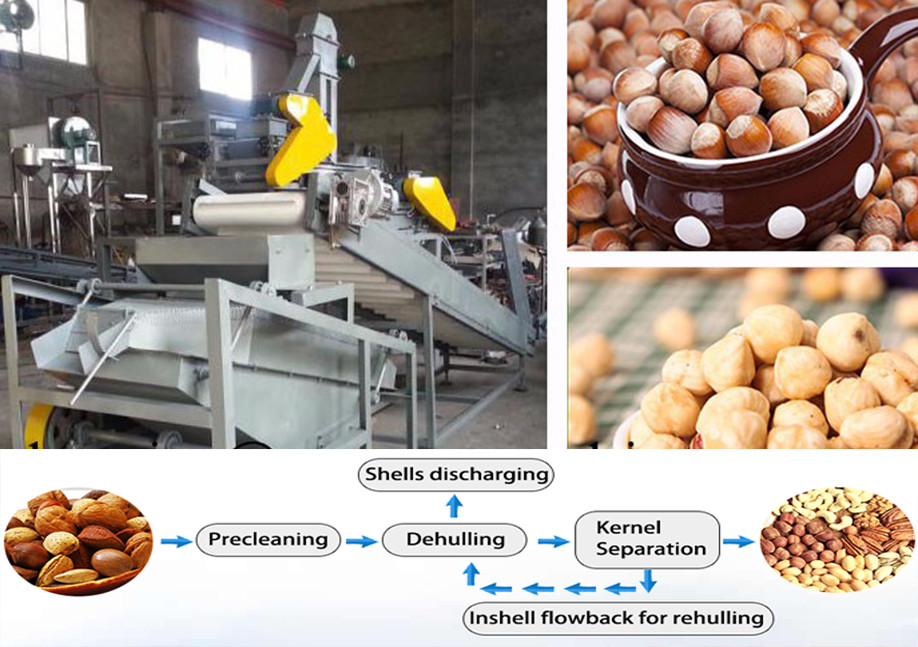

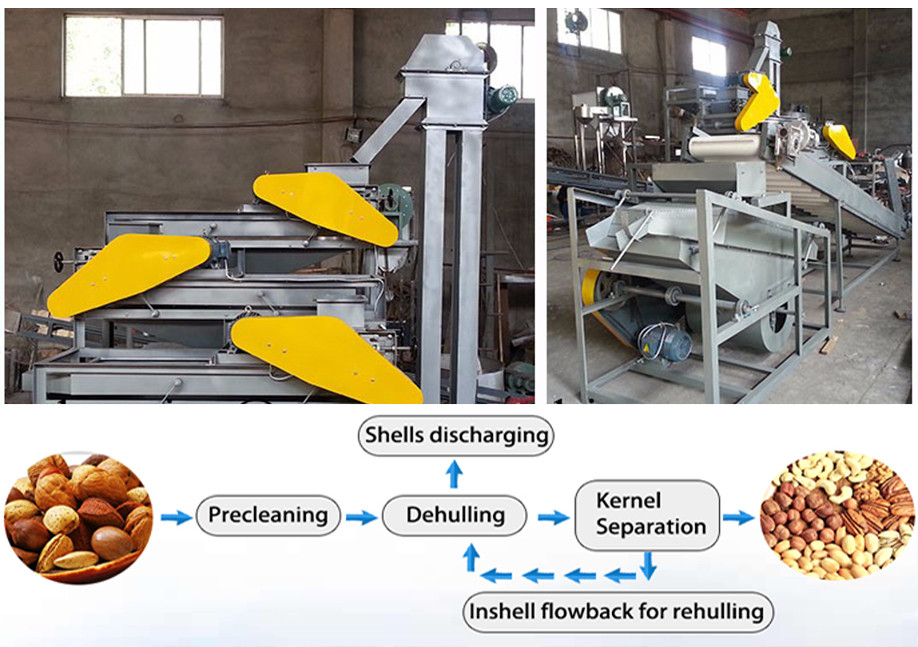

Shandong Microwave Machinery Co.,Ltd.Barley Dehuller and separating equipmentcan cleaning, de-hulling, removing shells, separating, re-separating, etc. Barley Dehuller and separating equipment will be returned to the dehuller for re-hulling again automatically by Barley Dehuller and separating equipmentmaterials-returning system, thus automation degree has been greatly improvedmachine with little percentage broken kernels rate and separate seed from shell in high rate , machine with automatic feeding of seeds, and easy operation and maintenance.

Component of Barley Dehuller and separating equipment

Small Paddy Corn Grain Drying Machine is consisted of the following eight parts: Hopper, Material Hoist, Muti-functional Impurities Remover, Bucket Elevator, Hulling Machines(4 sets), Vibrating Conveying and Separating Machine, Wind-recycling Unshelled Materials System and Controller Cabinet

Small Paddy Corn Grain Drying Machine

Feature:

Grain Drying

Machine is electric heating , through hot air from the pan, then drying the the raw material

product introduction :

1.Small Grain Drying Machine is applicable for drying various grain and plastic particle

2.RFC Series Heated-Air Dryer can thoroughly dry the raw materials and can save labor,improve quality and drop the cost,and assure 100% qualification for plastic products.

3.Adopt fully stainless steel with complete materials cleaning,design with bended hot air pipe for avoiding

product advantage:

When the ordinary Dryer to dry rice, because the raw material is still, the hot-blast air can’t penetrate completely, just heat some parts, so the raw material is easy to the ordinary can’t reach the Comprehensive drying effect.

The design is of two level spiral quick delivery, The first level deliver the materials quickly into the barrel, and the second level continuously rapid lift the raw material to the upper of the barrel and then throw the raw material with deliquescence scattered, while the hot air from the center of the barrel bottom blown out all around. Smoothly move the raw material from bottom to top to conduct a comprehensive heat transfer and dynamic drying process.

burn caused by powder in hot air pipe.

Technical parameters:

Model |

GGHG-500 |

Capacity |

500kg/time |

Hopper Capacity |

500L |

Speed of mainshaft |

330 (r/min) |

Motor power |

3kw |

Heating power |

24kw |

Voltage |

380V/50HZ |

Machine size |

1000*2700mm |

Model |

GGHG-1000 |

Capacity |

1000kg/time |

Hopper Capacity |

1000L |

Speed of mainshaft |

330 (r/min) |

Motor power |

3 kw |

Heating power |

36 kw |

Voltage |

380V/50HZ |

Machine size |

1300*2880mm |

Model |

GGHG-3000 |

Capacity |

3000kg/time |

Hopper Capacity |

4800L |

Speed of mainshaft |

330 (r/min) |

Motor power |

4kw |

Heating power |

48kw |

Voltage |

380V/50HZ |

Machine size |

1800*3500mm |

Packaging & Shipping

Packaging & Shipping1.Packaging Specification:

Outside Package:Wooden Packing as Exportand Standard.

Inner Package:Strech Film

2.Delivery time:

5-10days after received 40% of the whole payment.

3.About Shipping:

We can be responsible for the shipping,of course,we can also accept and cooperate with your agent if you have shipping forwarder in China

Our Services1.Quality Guarantee Terms:

Quality guarantee term is for one year. Malfunctions which are caused by machine-self and quality will be responsible for our manufacturer. Other malfunctions which are caused by operation mistakes, man-made problems, etc will be responsible for clients-self.

But we will provide the life-long after-sale service for the machine!

2.About MOQ(Minimum Order Quantity):

We are specialized in wholesales of food machinery, so the agent in overseas will be highly appreciated !The best quality with best price,to achieve the win-win cooperation!

3.Overseas Service

Our engineer can go to your country for installation and maintain according to customer's requirements

Payment TermsT/T( Telegraphic Transfer ):

40% as deposit, after seen the copy of the B/L sent by fax ,the balance of 60% should be effected .

Western Union:

Fast and convenient ,popular in the international trade!

Trade Assurance(Secure Payment):

---On-time shipment and pre-shipment product quality safeguards

--- Refund up to the covered amount agreed with your supplier

We and Customers

Name Card

Name Card

Shandong Microwave Machinery Co.,Ltd. is a Barley Dehuller and separating equipment factory specializing in the production of Small Paddy Corn Grain Drying Machine, scientific research, manufacturing,installation, commissioning.Shandong Microwave Machinery Co.,Ltd.can provide Barley Dehuller and separating equipmentcustomers with design and services of 1-2000 tons Small Paddy Corn Grain Drying Machine. Shandong Microwave Machinery Co.,Ltd. have finished hundreds of successful projects Barley Dehuller and separating equipmentover the years: peanut oil, soybean oil, rapeseed oil,cottonseed oil, sunflower oil, sesame oil, animal oil,grape seed oil, acer truncatum oil, peony seed oil, walnut oil, hemp seed oil, pine oil, tea seed oil, papaya oil, milk thistle seed, and other special type Barley Dehuller and separating equipmentoil. Shandong Microwave Machinery Co.,Ltd. have independent

import and export department. Shandong Microwave Machinery Co.,Ltd. Barley Dehuller and separating equipmentequipment has been successfully exported to more than ten countries: Russia, Australia, India, Afghanistan, Cameroon,and so on.

Contact us:

Carrie-Sales manager

Small Paddy Corn Grain Drying Machine

Web: www.epier.com

Email: [email protected]

Skype:leaderfoodmachine10

Moblie:0086-15020017267(also WhatsApp)