Food grade 304 stainless steel corn grinder mill,small grinder mill with CE from Shandong Microwave Machinery Co.,Ltd.

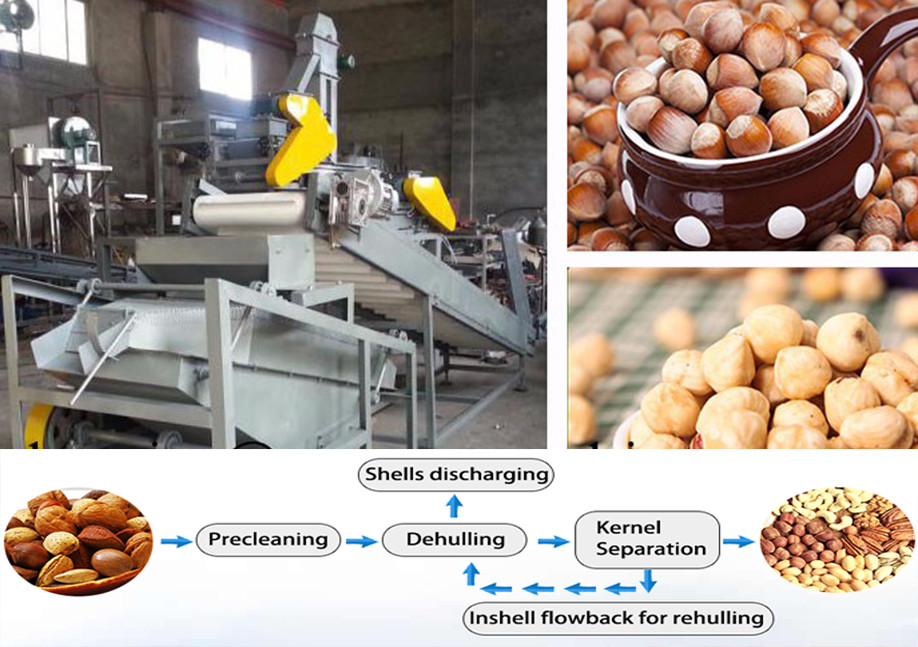

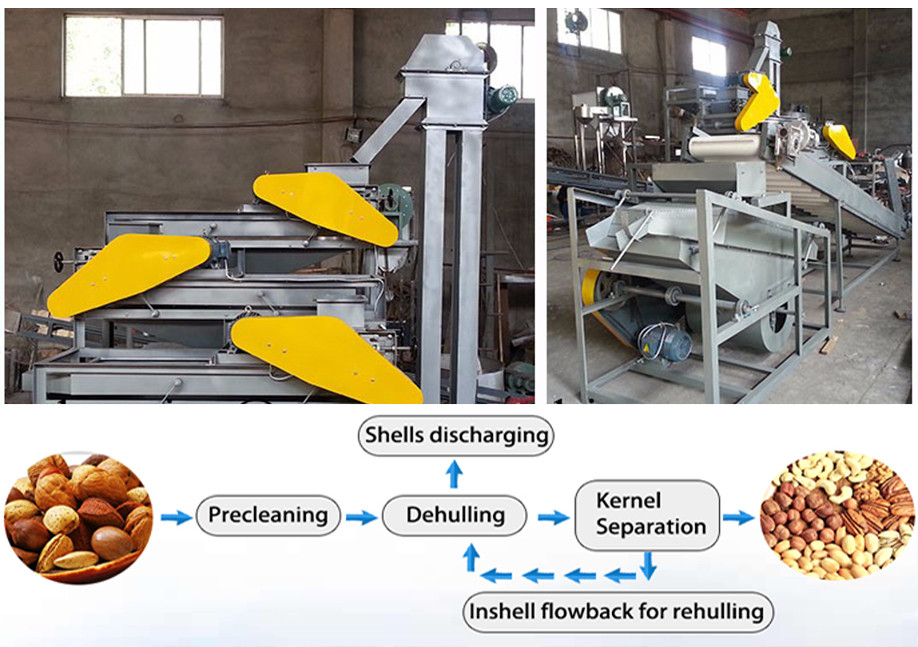

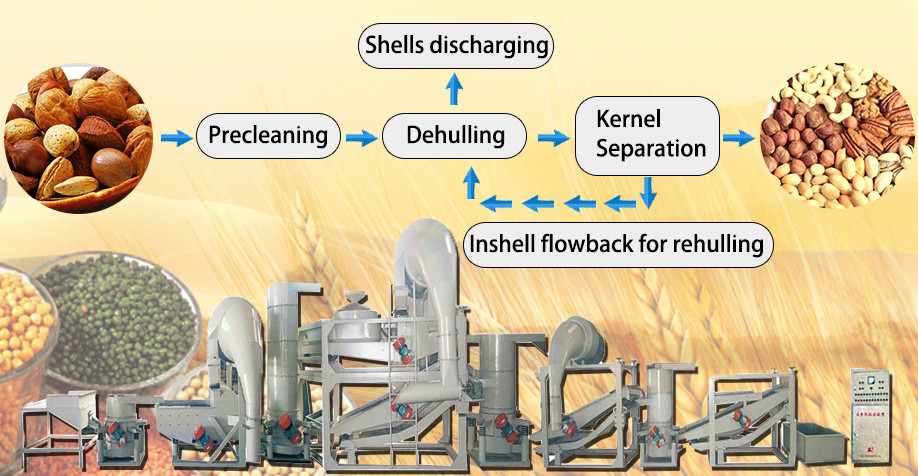

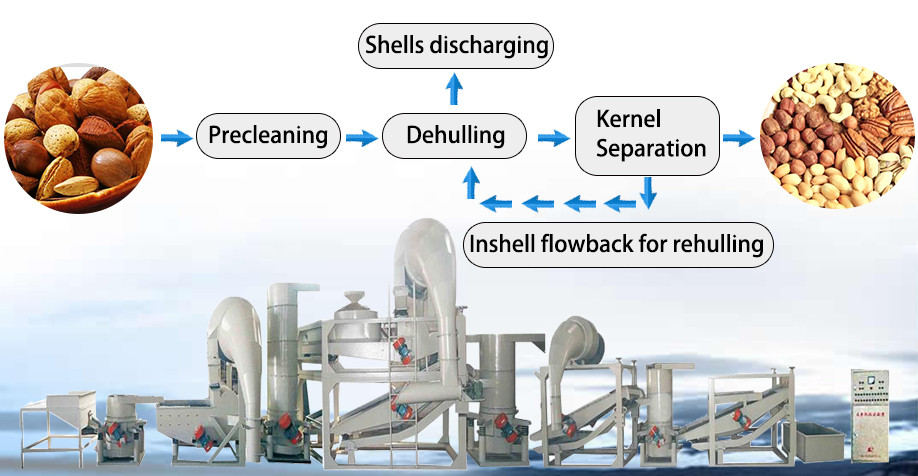

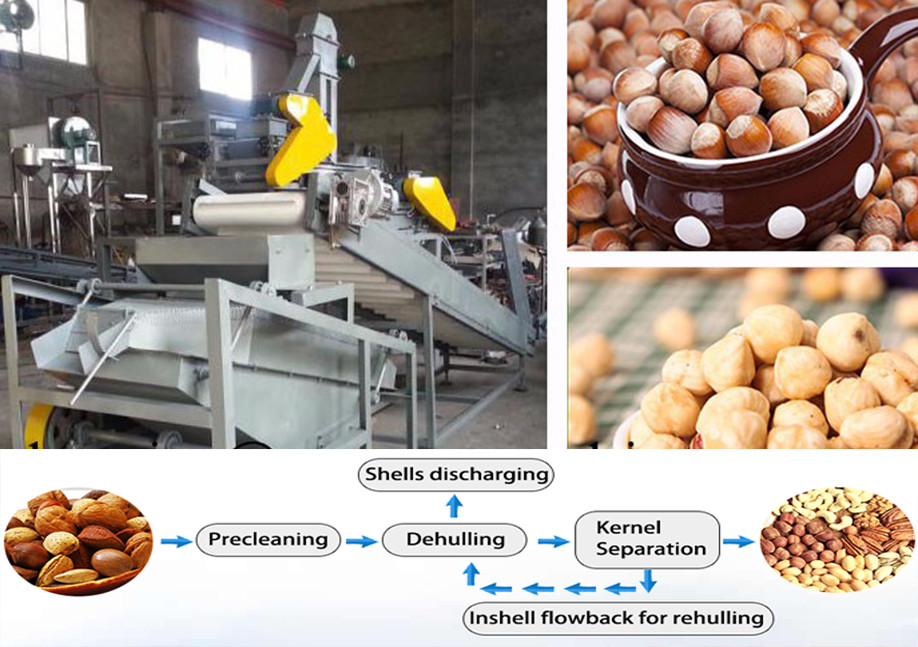

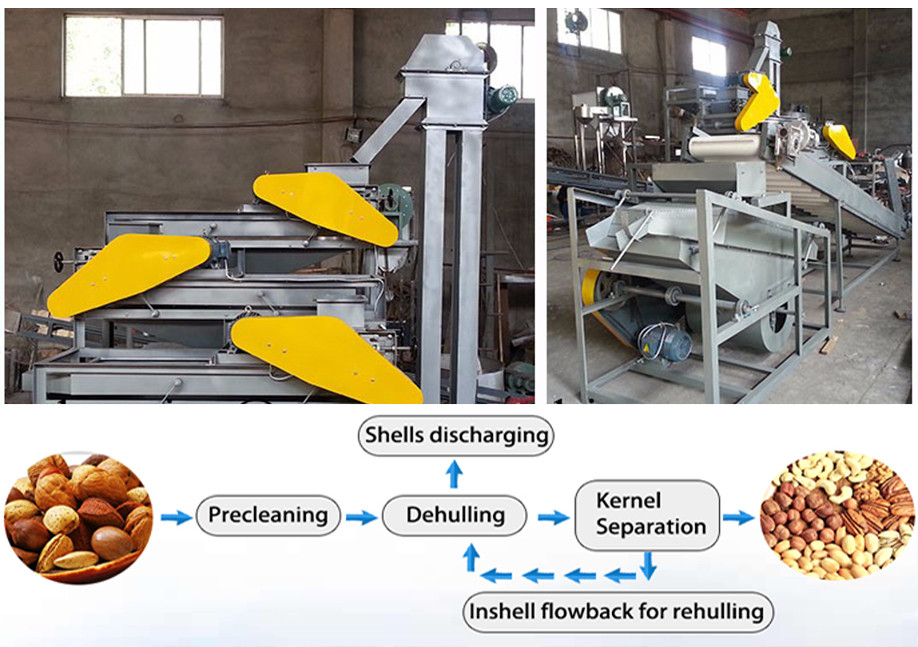

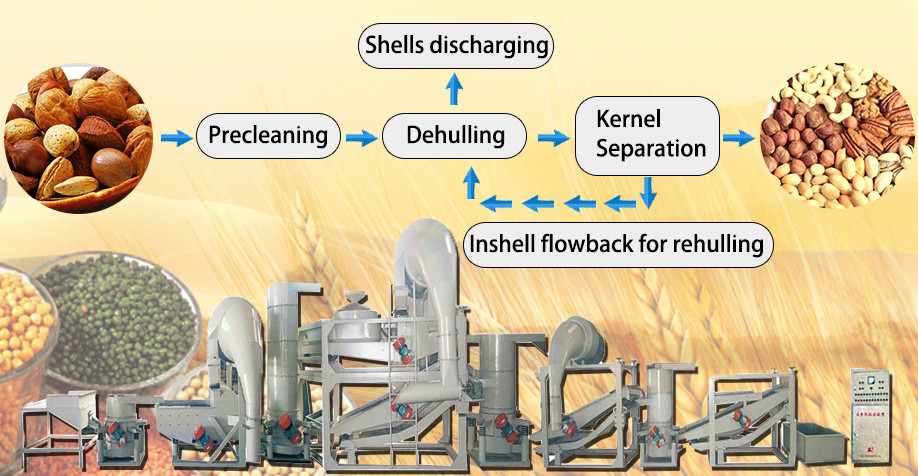

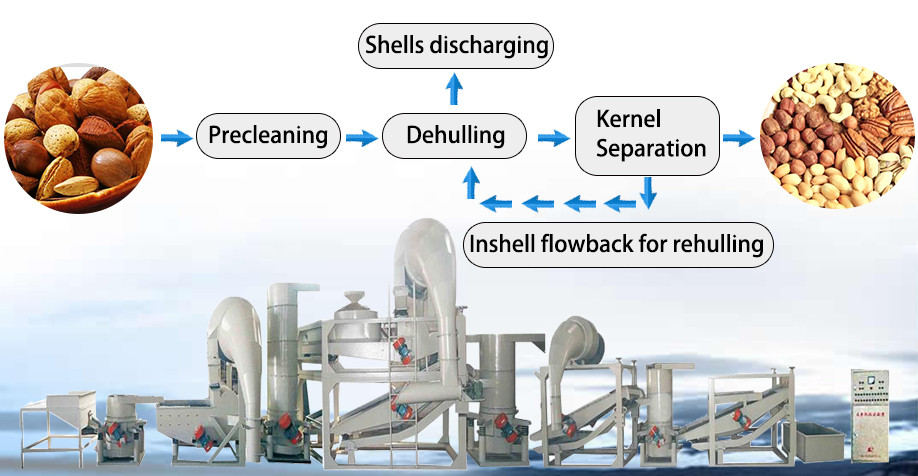

Food grade 304 stainless steel corn grinder mill,small grinder mill with CE is mainly used for shelling all kinds of hard shell nuts,such as almond,hazelnut,pistachio,camellia fruit and so on.

There are two type of Pine Nuts dehulling and separating equipment ,single stage type and three stage type. Take three stage type for example.Food grade 304 stainless steel corn grinder mill,small grinder mill with CE is composed of sheller and hoister.Food grade 304 stainless steel corn grinder mill,small grinder mill with CE is automatic feeding with the hoister.Food grade 304 stainless steel corn grinder mill,small grinder mill with CE can shell hard nuts with three different levels at the same time.By adjusting the clearance of all levels of processing roller without grading the nuts,you can shell Food grade 304 stainless steel corn grinder mill,small grinder mill with CE at one time.

Food grade 304 stainless steel corn grinder mill,small grinder mill with CE has reasonable designment,with low damage rate.Food grade 304 stainless steel corn grinder mill,small grinder mill with CE is the most ideal hard nuts processing equipment currently.Food grade 304 stainless steel corn grinder mill,small grinder mill with CE professional use for broken the hard shell ,like the apricot and filbert to change the distance between the rollers of this machine ,can broken the different size shell of the products .because the size of the shell is different ,so Food grade 304 stainless steel corn grinder mill,small grinder mill with CE is better to broken the big size ,then broken the smaller size.

Shandong Microwave Machinery Co.,Ltd. are committed to every machine before delivery through professional commissioning debugging To ensure that Food grade 304 stainless steel corn grinder mill,small grinder mill with CE is best for you.

Food grade 304 stainless steel corn grinder mill,small grinder mill with CE

Product Description

Instructions:

1. Open the upper cover and put the material inside ;

2. Close the upper cover tightly;

3. Plug in and turn on the timer switch, then turn on the switch for grindomg( Rolling sound will

be heard);

4. Turn off the switch ( when you hear the sound rolling evenly, the material has been grinded into powder. Then you can turn off the switch.

5. Open the upper cover and take the powder out.

Technical Parameters:

model |

Grinding capacity(g) |

Voltage (V) |

Output(W) |

Rotating speed (RPM) |

Weight (kg) |

Dimension (L*W*H mm) |

CHSF-100A |

100 |

220 |

560 |

28000 |

3.2 |

140*140*380 |

CHSF-200A |

200 |

220 |

800 |

28000 |

4.2 |

175*175*390 |

CHSF-300A |

300 |

220 |

1200 |

28000 |

6 |

190*190*330 |

CHSF-400A |

400 |

220 |

1200 |

25000 |

7 |

210*210*345 |

CHSF-500A |

500 |

220 |

1600 |

25000 |

9 |

220*220*400 |

CHSF-800A |

800 |

220 |

1600 |

25000 |

10 |

230*230*410 |

CHSF-1000A |

1000 |

220 |

1800 |

25000 |

10.5 |

240*240*420 |

Brief Introduction:

The Multi-functional high-speed grinder features fine structure, low noise, small size, no

vibration, compact appearance and easy operation.

It can grind all kinds of corns and grains into fine powder at 50-300 mesh.

It is widely used in families, clinic, hospital, pharmacy and institute laboratories.

Important Attentions:

- The materials ready for grinding must be dry. And wet, moisture or oil materials are not suitable to be grinded into powder.

- Each input material shall not exceed the rated weight or half capacity of grinding cylinder so that there is enough space for powder.

- After switch on, if you find the material is wet or excessive in weight, it will jam the blade and stop the motor by giving warning noise. Now you must plug out immediately to prevent motor from being damaged. And remove the jammed object. Then restart grinding.

- The grinding work usually needs 30 seconds to 1 or 2minutes. Over time will cause bearing overheating.

- The machine cannot keep continuous working. If you have much grinding work, we must have several minutes gap to avoid overheating of bearing and damaging motor.

- The machine must be operated on a good work platform safely. And be careful for electric voltage, electrical grounding, and wires to avoid any accidents.

- After the machine is used for a long time, you must check the carbon brush, blades and its fixing screw regularly. If you find it is damaged, replace them with new spare parts.

- If you find that the motor stops rotating, you must cut off power supply and check wire, plug, fuses, and carbon brush. If necessary, replace them with new spare parts. If the motor still does not work, please go to professional technician for repairing.

- If you find the power cord damaged, you must replace with special one.

- If the timer fails to work, you must stop grinding. It is forbidden to change the electrical route to continue. You must replace the 5minute timer designated by the factory by professionals to avoid mechanical or personal accidents.

- Itâs forbidden to use the water to wash the grinder cylinder and itâs also forbidden to open the upper cover after power on.

- When the machine is not in use, it must be kept in dry, clean and ventilated place.

Accessories:

1. Small blade:1 pc;

2. Big blade: 1 pc;

3. Brush: 1 pc;

4. Carbon brush: 1 pc;

5. Fuse: 2 pcs;

Packaging & Shipping

Package and Shipment: With Cartons by LCL

Our Services

Before sales,we can introduce our materials and supply professional suggestion as per our

marketing experience.

After sales, if not satisfy with our quality, we accept to return parcel. timely delivery, quality

guarantee,welcome inquire.

We promise timely delivery and quality guaranteed,

>95% customer satisfaction !

FAQ

1, Q: How about the after service?

A: We have a strong team, special for after service. Machine guarantee for one year. Within warranty period, if there are problems, not caused by human improper operation, we will charge of it. We will send the replace parts for free and technical guidance.

2, Q: How to ensure the transaction security ?

A: We focus in this field more than 10 years. And we are the gold member of alibaba. We run the foreign business on Alibaba for many years and have a very good credit .

3, Q: Where is your factory located? How can I visit there?

A:Our factory is located in Zhengzhou City, Henan province. You can fly to Xinzheng international airport and or by high-speed train directly. Our company will pick

you up .

4, Q:How does your factory do regarding quality control?

A:Quality is priority. We always attach great importance to quality controlling from

the beginning.

5.Q: How to place the order?

A: First we will recommend the suitable machine according to customer's requirements. If everything is ok, we will make the proforma invoice for you . After the invoice confrimed, you can make payment.

After we received the money,we will arrange to delievery the machine.

6. Q: What is the producing time?

A: Usually ,we have the stock,if the order is large or machine need to customize ,we can negociate it.

7.Q: Whatâs the payment method ?

A: Normally, we accept the payment by TT, Western Union. You can also choose

to pay through Alibaba. For it , we can discuss.

Contact information

Welcome your inquiry ! If you are interested in our products and have any questions, pls don't hesitate to contact with me.

Contact us:

Carrie-Sales manager

Shandong Microwave Machinery Co.,Ltd.

Web: www.epier.com

Email: [email protected]

Skype:leaderfoodmachine10

Moblie:0086-15020017267(also WhatsApp)

Shandong Microwave Machinery Co.,Ltd.is a Pine Nuts dehulling and separating equipment factory specializing in the production of Food grade 304 stainless steel corn grinder mill,small grinder mill with CE, scientific research,manufacturing,installation, commissioning.Shandong Microwave Machinery Co.,Ltd.can provide Pine Nuts dehulling and separating equipmentcustomers with design and services of 1-2000 tons Food grade 304 stainless steel corn grinder mill,small grinder mill with CE. Shandong Microwave Machinery Co.,Ltd. have finished hundreds of successful projects Pine Nuts dehulling and separating equipmentover the years: peanut oil, soybean oil, rapeseed oil, cottonseed oil, sunflower oil, sesame oil, animal oil,grape seed oil, acer truncatum oil, peony seed oil, walnut oil, hemp seed oil, pine oil, tea seed oil, papaya oil, milk thistle seed, and other special type Pine Nuts dehulling and separating equipmentoil. Shandong Microwave Machinery Co.,Ltd. have independent import and export department. Shandong Microwave Machinery Co.,Ltd. Pine Nuts dehulling and separating equipmentequipment has been successfully exported to more than ten countries: Russia, Australia, India, Afghanistan, Cameroon,and so on.