Commercial automatic corn/maize flour mill,flavoring grinder machine from Shandong Microwave Machinery Co.,Ltd.

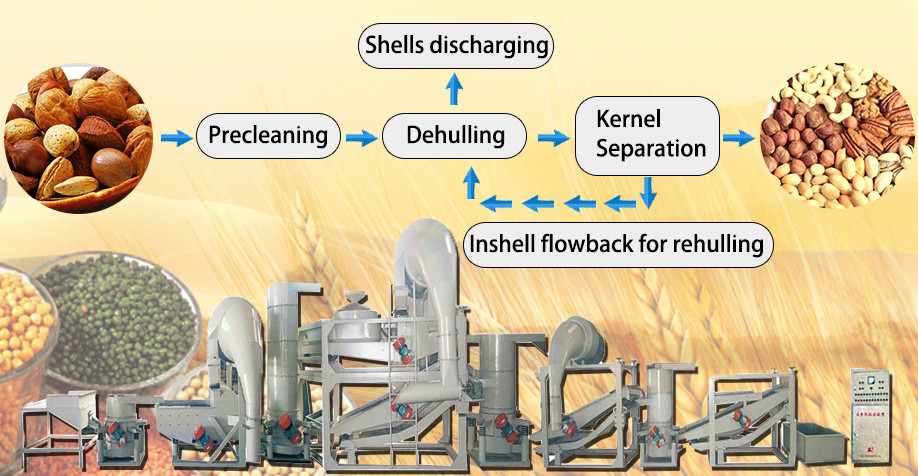

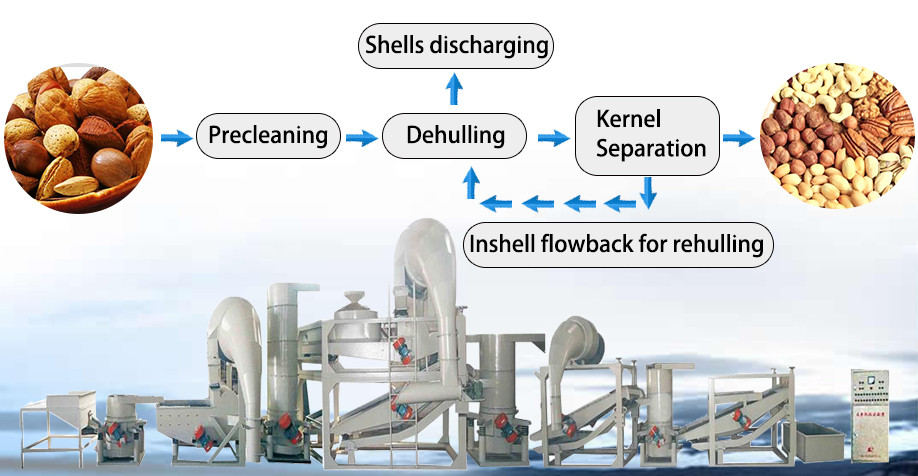

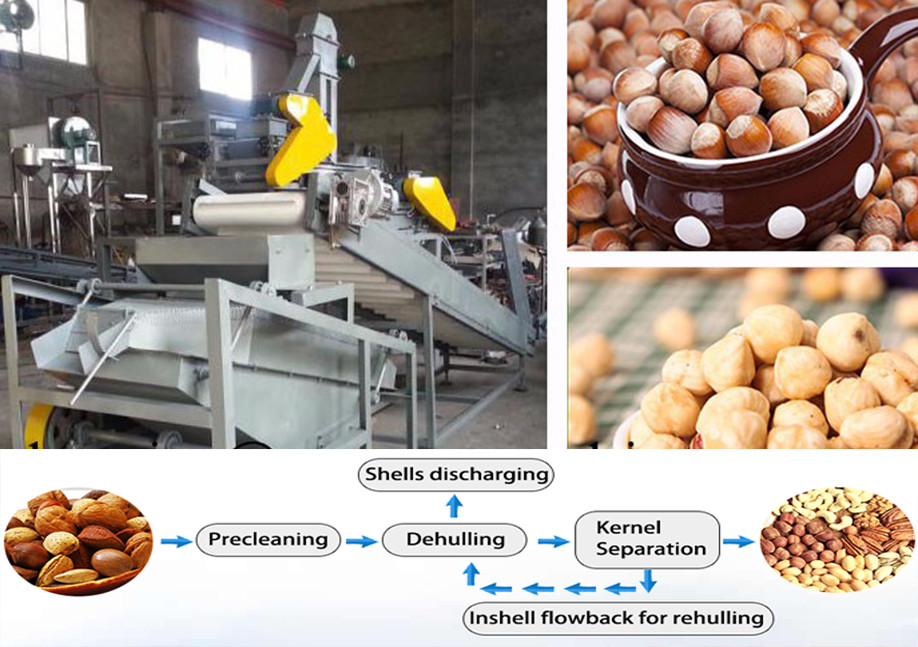

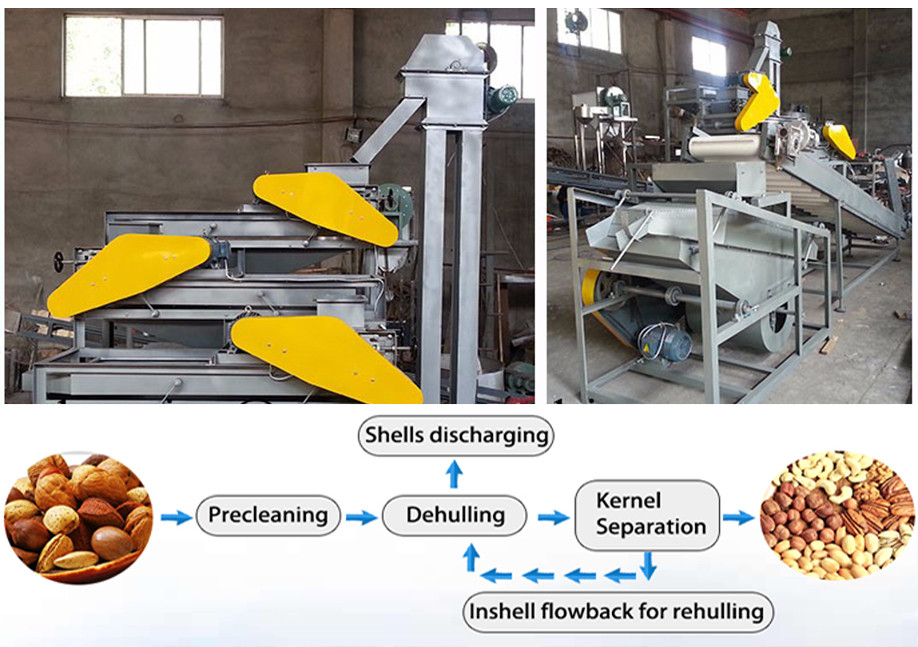

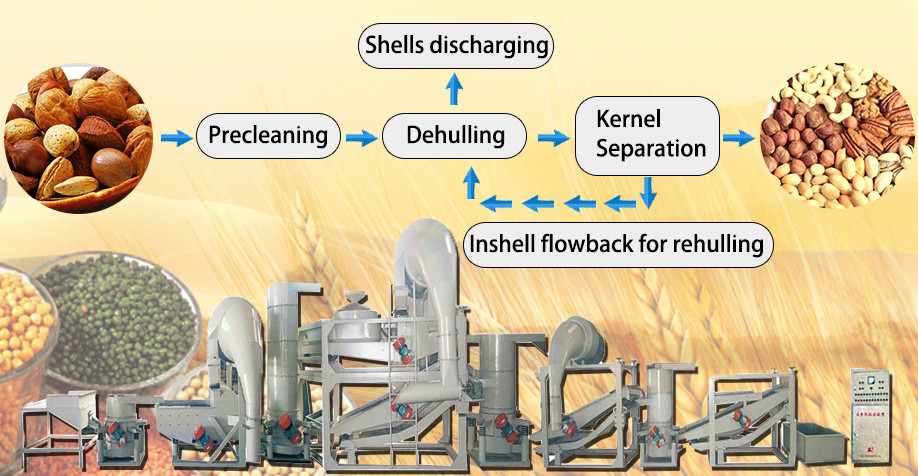

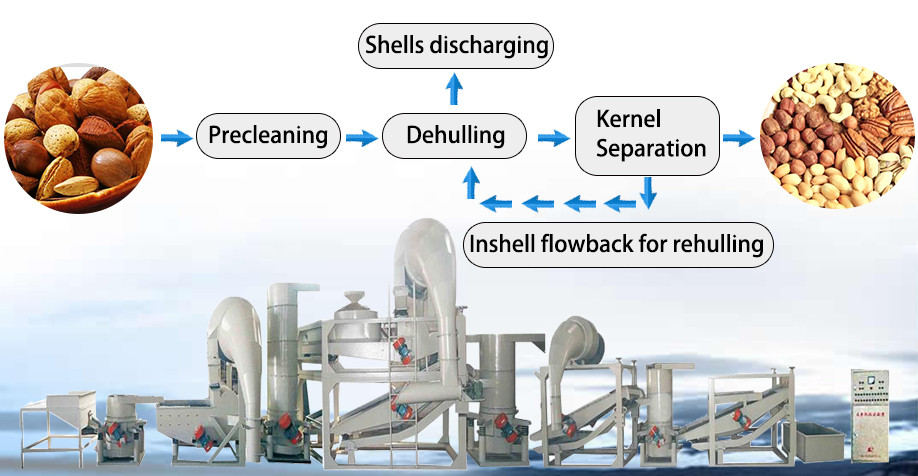

Commercial automatic corn/maize flour mill,flavoring grinder machine is mainly used for shelling all kinds of hard shell nuts,such as almond,hazelnut,pistachio,camellia fruit and so on.

There are two type of Pine Nuts dehulling and separating equipment ,single stage type and three stage type. Take three stage type for example.Commercial automatic corn/maize flour mill,flavoring grinder machine is composed of sheller and hoister.Commercial automatic corn/maize flour mill,flavoring grinder machine is automatic feeding with the hoister.Commercial automatic corn/maize flour mill,flavoring grinder machine can shell hard nuts with three different levels at the same time.By adjusting the clearance of all levels of processing roller without grading the nuts,you can shell Commercial automatic corn/maize flour mill,flavoring grinder machine at one time.

Commercial automatic corn/maize flour mill,flavoring grinder machine has reasonable designment,with low damage rate.Commercial automatic corn/maize flour mill,flavoring grinder machine is the most ideal hard nuts processing equipment currently.Commercial automatic corn/maize flour mill,flavoring grinder machine professional use for broken the hard shell ,like the apricot and filbert to change the distance between the rollers of this machine ,can broken the different size shell of the products .because the size of the shell is different ,so Commercial automatic corn/maize flour mill,flavoring grinder machine is better to broken the big size ,then broken the smaller size.

Shandong Microwave Machinery Co.,Ltd. are committed to every machine before delivery through professional commissioning debugging To ensure that Commercial automatic corn/maize flour mill,flavoring grinder machine is best for you.

Commercial automatic corn/maize flour mill,flavoring grinder machine

Product Description

Main application:

The machine is suitable for material crushing in pharmaceutical, chemical and food

industries

Working principle:

This machine use the tooth plate and fixed means of relative motion, make shattered by the impact, friction and comprehensive function such as the impact among the materials themselves are crushed. This machine of simple structure, strong, stable operation, crushing effect is good, crushed material can directly by the host grinding cavity vent, the particle size can be obtained by changing sieve different aperture. Casing wall all the machined surface smooth, changed the former type wall roughness, the phenomenon of accumulated powder, medicines, food, chemical and other production full of "GMP" standard requires all machine made of stainless steel material, 30 and 40 type of crushing chamber can match water cooling jacket, and has reached the international advanced level.

Technical parameters:

Model |

20type |

30type |

40type |

capacity(kg/h) |

20-150 |

30-300 |

40-800 |

Revolving Speed (r/min) |

5800 |

4500 |

3800 |

Maximum Grain Size(mm) |

10 |

12 |

|

Grinding Fineness |

12-120 mesh |

12-120mesh |

12-120mesh |

power(kw) |

3 |

5.5 |

11 |

weight(kg) |

200 |

320 |

550 |

size(mm) |

550*600*1250 |

500*700*1450 |

800*900*1550 |

Packaging & Shipping

FAQ

1, Q: How about the after service?

A: We have a strong team, special for after service. Machine guarantee for one

year. Within warranty period, if there are problems, not caused by human improper operation, we will charge of it. We will send the replace parts for free and technical guidance.

2, Q: How to ensure the transaction security ?

A: We focus in this field more than 10 years. And we are the gold member of

alibaba. We run the foreign business on Alibaba for many years and have a very

good credit .

3, Q: Where is your factory located? How can I visit there?

A:Our factory is located in Zhengzhou City, Henan province. You can fly to Xinzheng international airport and or by high-speed train directly. Our company will pick

you up .

4, Q:How does your factory do regarding quality control?

A:Quality is priority. We always attach great importance to quality controlling from

the beginning.

5.Q: How to place the order?

A: First we will recommend the suitable machine according to customer's

requirements. If everything is ok, we will make the proforma invoice for you . After

the invoice confrimed, you can make payment.

After we received the money,we will arrange to delievery the machine.

6. Q: What is the producing time?

A: Usually ,we have the stock,if the order is large or machine need to customize ,

we can negociate it.

7.Q: Whatâs the payment method ?

A: Normally, we accept the payment by TT, Western Union. You can also choose

to pay through Alibaba. For it , we can discuss.

Contact information

Welcome your inquiry ! If you are interested in our products and have any questions, pls don't hesitate to contact with me.

Contact us:

Carrie-Sales manager

Shandong Microwave Machinery Co.,Ltd.

Web: www.epier.com

Email: [email protected]

Skype:leaderfoodmachine10

Moblie:0086-15020017267(also WhatsApp)

Shandong Microwave Machinery Co.,Ltd.is a Pine Nuts dehulling and separating equipment factory specializing in the production of Commercial automatic corn/maize flour mill,flavoring grinder machine, scientific research,manufacturing,installation, commissioning.Shandong Microwave Machinery Co.,Ltd.can provide Pine Nuts dehulling and separating equipmentcustomers with design and services of 1-2000 tons Commercial automatic corn/maize flour mill,flavoring grinder machine. Shandong Microwave Machinery Co.,Ltd. have finished hundreds of successful projects Pine Nuts dehulling and separating equipmentover the years: peanut oil, soybean oil, rapeseed oil, cottonseed oil, sunflower oil, sesame oil, animal oil,grape seed oil, acer truncatum oil, peony seed oil, walnut oil, hemp seed oil, pine oil, tea seed oil, papaya oil, milk thistle seed, and other special type Pine Nuts dehulling and separating equipmentoil. Shandong Microwave Machinery Co.,Ltd. have independent import and export department. Shandong Microwave Machinery Co.,Ltd. Pine Nuts dehulling and separating equipmentequipment has been successfully exported to more than ten countries: Russia, Australia, India, Afghanistan, Cameroon,and so on.