Shandong Leader Machinery Co.,ltd. has finished hundreds of successful projects over the years: peanut oil, soybean oil, rapeseed oil, cottonseed oil, sunflower oil, sesame oil, animal oil,grape seed oil, acer truncatum oil, peony seed oil, walnut oil, hemp seed oil, pine oil, tea seed oil, papaya oil, milk thistle seed, and other special type oil.We have independent import and export department. Our equipment has been successfully exported to more than 100 countries: Russia, Australia, India, Afghanistan, Cameroon,and so on.

Product Description:

According to customers on the type of oil, daily processing volume, oil standards and other conditions of the requirements of processing customization, size, refining the number of cans, product prices are different.

Industrial vacuum microwave banana plantain chips drying machine /vacuum microwave banana slices dryer

Product Description

Microwave vacuum batch dryer

| Model | BDMD-M-V-30 | BDMD-M-V-20 | BDMD-M-V-6 |

| Microwave Power (KW) | 30 | 20 | 6 |

| Loading Area (m2) | 3.3 | 2.6 | 1 |

| Input Voltage (V) | 380 | 380 | 380 |

| Operating Temperature (℃) | 40-85 | 40-85 | 40-85 |

| Microwave Leakage Rate (MW/cm2) | ≤1 | ≤1 | ≤1 |

| Vacuum Degree (MPa) | -0.08 ~ -0.094 | -0.08 ~ -0.094 | -0.08 ~ -0.094 |

| Gross Weight (KG) | 3500 | 3000 | 1200 |

| Vacuum Pump Power (KW) | 7.5 | 7.5 | 1.5 |

| The Number of Tray | 10 | 8 | 2 |

| Tray Size (mm) | 940×360×100 | 940×360×100 | (diameter) 650x100 |

| Overall Dimension (m) | 3×2×2.5 | 2.6×2×2 | 1.26×1.2×1.6 |

| Installation Area (m) | 5×3×3.2 | 4.5×3×2.7 | 3×2.2×2.3 |

| Cooling Water (m3/h) | 6 | 5 | 2 |

Following are the sizes of hot selling continuous microwave dryer.

| Microwave dryer Model | Microwave frequency (MHz) | Microwave power | Microwave leakage | Dryer dimension (m) | Installation area (m) |

| BDMD-F-P-20 | 2450±50 | 20kw | 1mW/cm2 | 7.0x1.1x1.7 | 9x3.5x2.5 |

| BDMD-F-P-30 | 2450±50 | 30kw | 1mW/cm2 | 8.0x1.1x1.7 | 10x3.5x2.5 |

| BDMD-F-P-40 | 2450±50 | 40kw | 1mW/cm2 | 9.0x1.1x1.7 | 11x3.5x2.5 |

| BDMD-F-P-50 | 2450±50 | 50kw | 1mW/cm2 | 10.0x1.1x1.7 | 12x3.5x2.5 |

| BDMD-F-P-60 | 2450±50 | 60kw | 1mW/cm2 | 11.0x1.1x1.7 | 13x3.5x2.5 |

| BDMD-F-P-70 | 2450±50 | 70kw | 1mW/cm2 | 12.0x1.1x1.7 | 14x3.5x2.5 |

| BDMD-F-P-80 | 2450±50 | 80kw | 1mW/cm2 | 13.0x1.1x1.7 | 15x3.5x2.5 |

| BDMD-F-P-100 | 2450±50 | 100kw | 1mW/cm2 | 16.0x1.1x1.7 | 18x3.5x2.5 |

| BDMD-F-P-120 | 2450±50 | 120kw | 1mW/cm2 | 18.0x1.1x1.7 | 20x3.5x2.5 |

| BDMD-F-P-150 | 2450±50 | 150kw | 1mW/cm2 | 21.0x1.1x1.7 | 23x3.5x2.5 |

| BDMD-F-P-200 | 2450±50 | 200kw | 1mW/cm2 | 27.0x1.1x1.7 | 29x3.5x2.5 |

Usage:

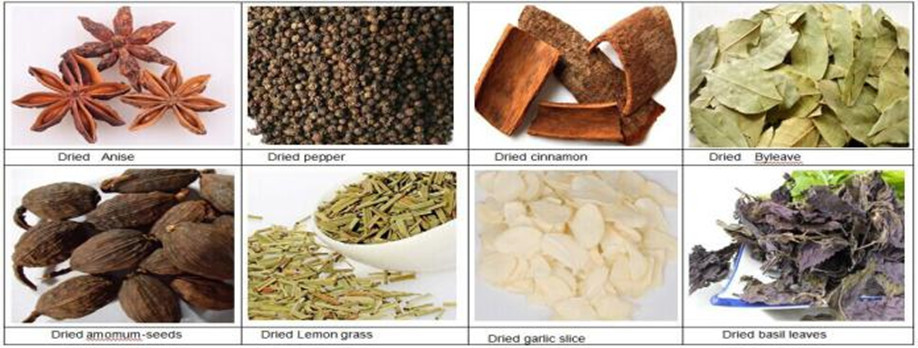

The microwave vacuum dryer is used to dry all kinds of fruits, vegetables, spices, seasonings, herbs in low temperature to preserve the original nutrition of them. We have speical microwave vacuum palm dates dryer, banana chips microwave vacuum dryer, microwave vacuum jam dryer, etc.

Advantage:

Microwave vacuum drying machine has a number of quantitative and qualitative advantages over conventional drying machines so that it becomes more and more popular. One main advantage is the place where the heat is generated, namely the product itself. Because of this, the effect of small heat conductivities or heat transfer coefficients does not play such an important role. Therefore, larger pieces of foods can be heated in microwave vacuum drying machine in a shorter time and with a more even temperature distribution. The another main advantages is the short drying time, low drying temperature of industrial vacuum microwave dryer oven. The third advantage is microwave vacuum dryer can prevent materials oxidation during drying and preserve nutrition well.

- Energy saving 30%-60%

- Drying speed 50% quicker

- Reduced CO2 emissions

- Increased drying efficiency and yield

- Drying temperature adjustable

- Suitable for drying all heat sensitive foods

Packaging & Shipping

Wooden packing for each set of microwave vacuum dryer if needed.

Soft packing is supplied.

Our Services

Our ServicesLD provides a full range of services and technical support for industrial microwave systems, for both drying oven and tunnel drying machine. The services include custom installations, preventive equipment maintenance, equipment upgrades and modifications and microwave system repair.

Company Information

FAQ

1. What is Microwave?

Microwaves are a form of electromagnetic energy with frequencies between 300 MHz and 300 GHz, generated by magnetrons under the combined force of an electric and a magnetic field perpendicular to each other.

2. What is the advantage of Microwave dehydrator compared to Conventional dehydrator?

Conventional dehydrator is a surface dehydration method, which is not only slow, but also non-uniform with the surfaces, edges and corners being much dehydrated than the inside of the material. The imperfect dehydration will cause product rejections, waste energy and extend process time.

Microwave fruit dehydrator and vegetable dehydrator is a direct method of dehydration. Energy is transferred through the material electro-magnetically, not as a thermal heat flux. Therefore, the rate of dehydration is not limited, the uniformity of heat distribution is greatly improved and dehydration time is reduced.

3. How about safety?

Using scientific structure and patented suppression system, LD industrial microwave dehydrator poses no threat of electromagnetic radiation to the health and safety of equipment operators.

4.What about maintenance?

In addition to downtime for cleaning and inspection, conventional dehydrators and heat exchangers need periodic servicing with an expensive inventory of parts and a highly trained labor force. For microwave dehydrator, the only part that requires maintenance is the magnetron. In the event of a malfunction or misuse through incorrect operation, this can easily be replaced in less than thirty minutes. Generally, LD recommends that the magnetron of industrial microwave dehydrator be replaced annually or after 8,000 hours of operation, whichever is sooner.

LD

You are here: Home >> Conti Dryer >> Microwave vacuum dryer for bananas

1. Industrial vacuum microwave banana plantain chips drying machine /vacuum microwave banana slices dryerPre-sale services:

Assistant of clients enable them to get rich and generous returns on their investments.

Select machine model;

Design and manufacture according to clients' special requirement;

Train technical personnel for clients.

AAA1

2. Industrial vacuum microwave banana plantain chips drying machine /vacuum microwave banana slices dryerServices during the sale:

Pre-check and accept machine ahead of delivery;

Help clients to draft solving scheme .

AAA2

3. Industrial vacuum microwave banana plantain chips drying machine /vacuum microwave banana slices dryerAfter-sale services:

Provide considerate services to minimize clients' worries.

Assist clients to prepare for the first construction scheme;

Install and debug the equipment;

Train the first-line operators;

Examine the equipment;

Take initiative to eliminate the troubles rapidly;

Provide perfect service.

AAA3

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: [email protected]