The tartary buckwheat dehulling & separating machine is a patented product of our company and is the independent intellectual property of Qiaopai company. and also it is the most widely used and better dehulling result in the world. During the dehulling process, the buckwheat kernel-shell can be separated automatically at the same time, and meanwhile sort out the brokens from kernels. It adopts dry method dehulling process, no preheating to buckwheat required beforehand. It feature easy operation, high persentage of kernels recovery, high persentage of whole kernels and perfect kernel-shell separation works......

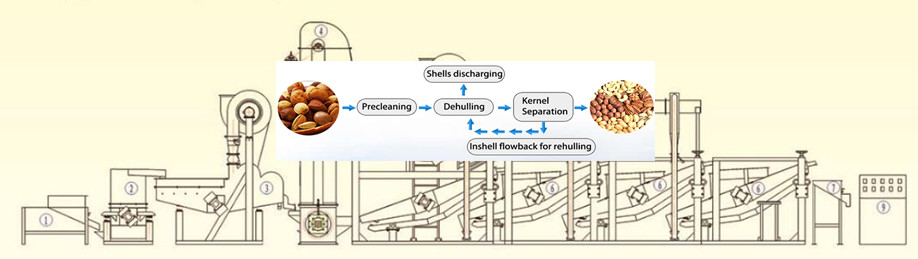

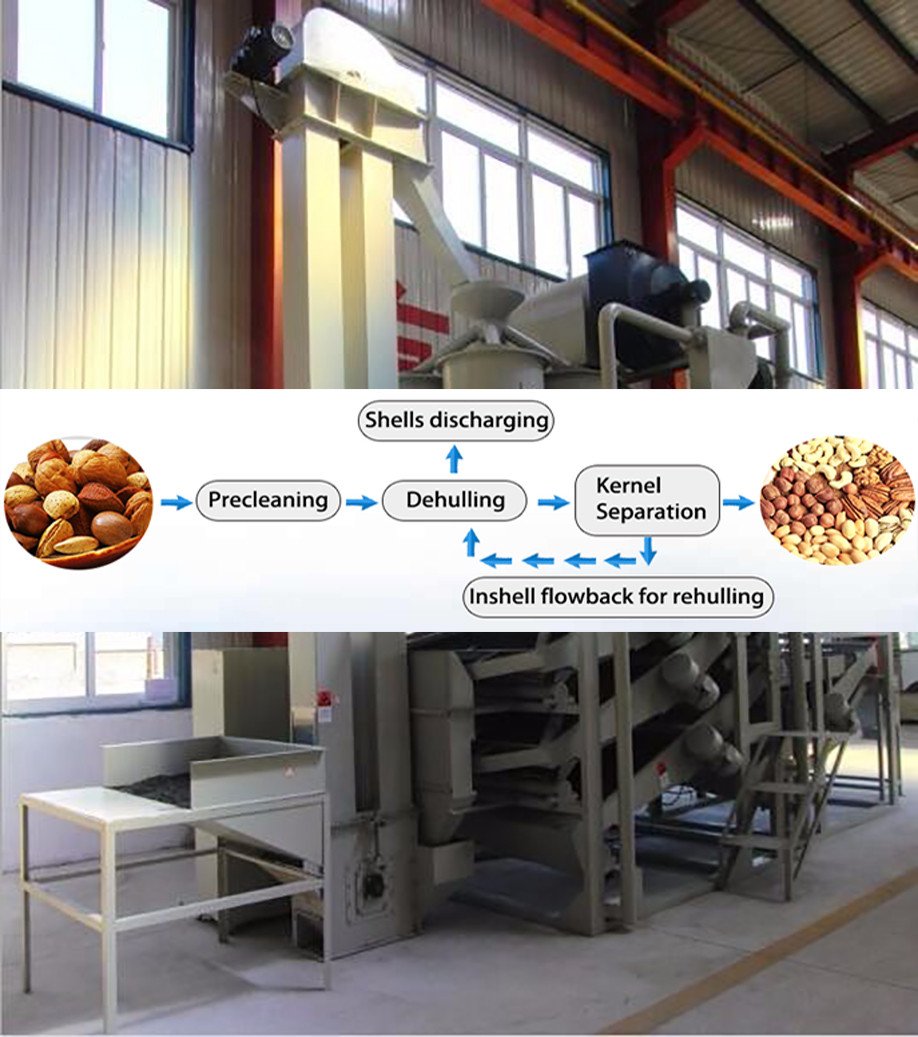

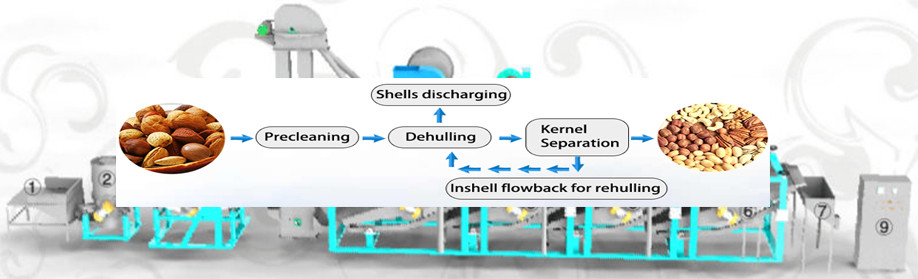

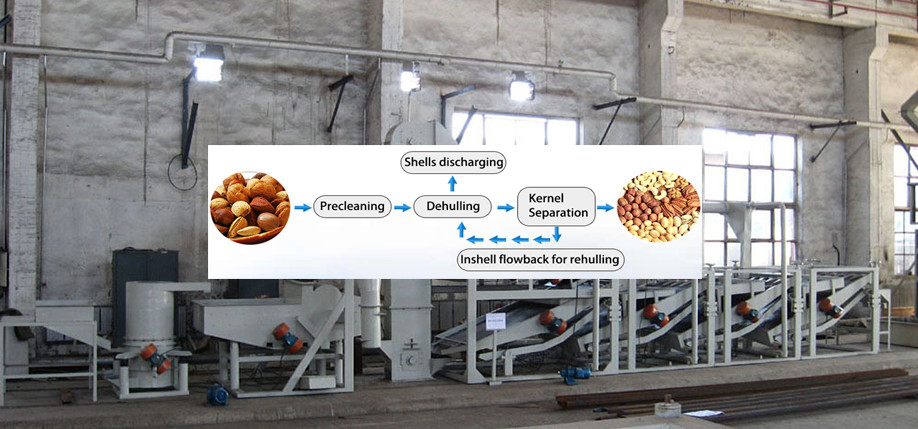

Process:

TFKQ150 Model main technical parameters:

Output capacity: 150kgs/hour minimum

% of inshell in final kernels: 2% maximum

Space occupied: 6.0m×2.8m

Height: 4.2m

TFKQ200 Model main technical parameters:

Input capacity: 300-400kgs/hour minimum

% of whole kernels: 98% min.

% of inshell in final kernels: 2% max.

Space occupied: 9.55m×3.4m

Height: 4.48m

Meantime, we also specialize in cleaning, dehulling & separating machines and equipments for Sunflower seed, Buckwheat, pumpkin seed, watermelon seed, oat, job’s tears, mung bean (green bean), perillaseed, linseed (flaxseed), safflower seeds, Silybum seed, almond, hazelnut, Gordon Euryale Seed (foxnut), Jatropha seed, acorn, etc. in China.