Specifications

1. CE, ISO9001:2008 & TUV certified2. Patent product

3. Twice dehuller

4. with frequency inverter

| [Functions and Features] |

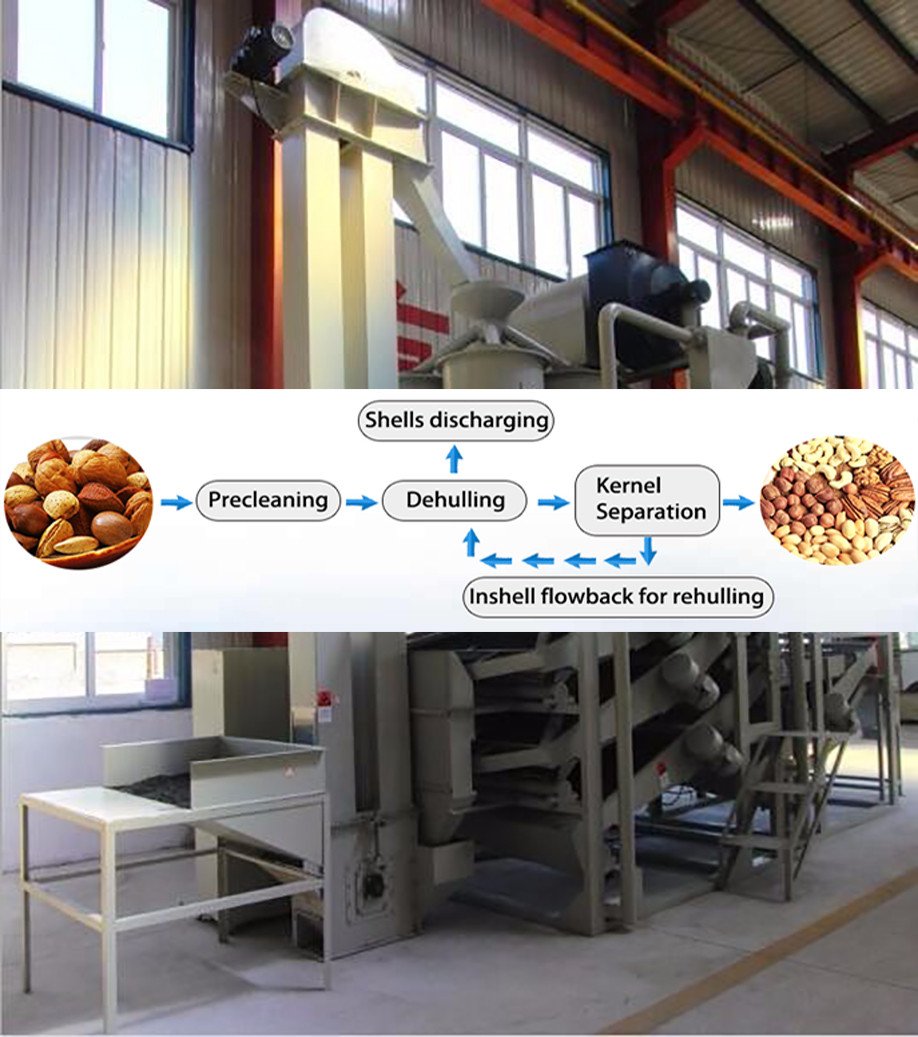

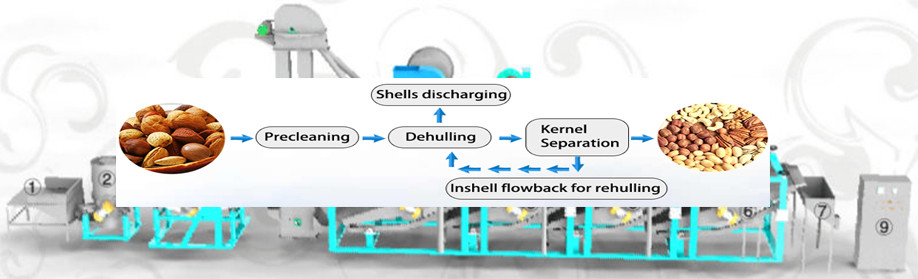

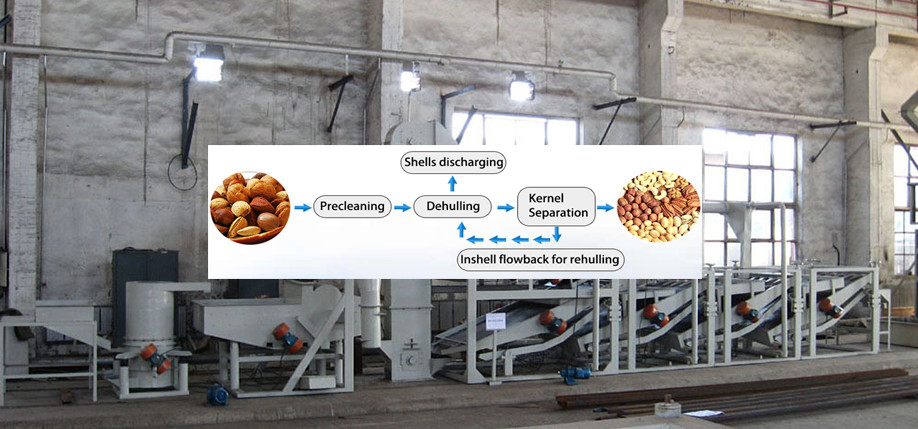

| Oats dehulling&separating equipment Model TFYM1000 is the patented product of our company and is the independent intellectual property of our company. It is designed for dehull and separate your oats.It features compact design, easy operation. It's the leading equipment in China for oats processing on the technical specifications like high persentage of dehulling and high persentage of whole kernels. It's the optimum equipment for oats pre-treatment of oats, meanwhile the difficult problem to dehull oats has been solved properly |

It consists of input hopper , bucket elevator, dehullers ,shells-discharging device , separating screen , reseparator , kernels collector , pneumatic device for back-flowing materials, electric control cabinet .

| [Technical parameters] |

| Power:12.25kw(380V) % of whole kerenls:95% min. % of inshell in final kernels: 2% max. Input capacity: 0.6-0.8mt/hour Space occupied: 7.3m×2.8m Height:3.9m Weight:2.8mt |

Meantime, we also specialize in cleaning, dehulling & separating machines and equipments for Sunflower seed, Buckwheat, tartary buckwheat, pumpkin/watermelon seed, mung bean (green bean), hemp seed, job tears, Silybum seed, almond, hazelnut, foxnut, Jatropha seed, acorn, peach inshell, etc. in China.