Why do you choose the Shandong Leader Machinery Co.,ltd. Air circulating drying chamber date drying machine/jujube dryer?

1.Healthy! Pure mechanical squeezing craft maximally keeps the nutrients of the oil plants.No chemical substances left

2. High working efficiency! Due to a high working efficiency of the screw oil press machinery,both time and power can be saved.

3. Long durability! All the parts are made of the most suitable material and treated with refined crafts, such as cemented quenching and tempering to increase the hardness, consequently the durability.

4. Air circulating drying chamber date drying machine/jujube dryerCost-effective! Low investment! The wearing parts on the oil press machinery such as the squeeze loop, squeeze spiral and squeeze bar are designed to be dismountable. When they are out of service period, users only need to replace them and there is no need to displace the whole machine.

Air circulating drying chamber date drying machine/jujube dryer

parameters

| NEW TYPE HEAT PUMP DRYER MODEL | |||||||

| Items | Unit | JK03RD | JK06RD | JK10RD | JK12RD | ||

| Production capacity | 1set | 300kg | 600kg | 1000kg | 1200kg | ||

| 2 sets | 600kg | 1200kg | 2000kg | 2500kg | |||

| Suitable drying chamber size | M3 | 10-30 | 30-40 | 40-50 | 60-70 | ||

| Heating capacity | Kw/h | 12 | 26 | 35 | 42 | ||

| Cooling capacity | Kw/h | 7.5 | 15 | 25 | 30 | ||

| Dehumidification amount | L/H | 10 | 25 | 50 | 60 | ||

| Compressor | 2.8 | 5.3 | 9.3 | 11.2 | |||

| Evaporator fan motors | 0.78 | 0.78 | 1.5 | 1.5 | |||

| Input power | Hot air circulating fan | kw | 2 | 2 | 2 | 2 | |

| Dehumidify fan motor | 0.37 | 0.37 | 0.55 | 0.55 | |||

| Auxiliary electric heater | 3 | 6 | 9 | 9 | |||

| Power supply | kw | 220v/380v | 380v/3ph/50hz or 60hz | ||||

| Total running current | A | 35/20 | 30 | 45 | 45 | ||

| Max hot air temperature | ℃ | 75 | |||||

| Min cooling temperature | ℃ | 8 | |||||

| Working ambient temperature | ℃ | -10-45 | |||||

| Mixture Refrigerant | kg | 2.5 | 4.5 | 8 | 9.75 | ||

| Weight | kg | 210 | 385 | 480 | 500 | ||

| length | 1650 | 1730 | 2100 | 2179 | |||

| Width | 960 | 1220 | 1460 | 1356 | |||

| Dimension | Height | mm | 1280 | 1280 | 1590 | 1930 | |

Features:

Cleaning, energy saving, labor saving1. Energy saving&Environmental protection

Adopt close dehumidify+circulating drying type,saving operating cost;

Without waste gas and waste heat pollution,low noise

2. Running Stable,operating easily

PLC+Touch Screen,running stable,operating easily;

Adopt PLC control,can setting different drying curve,

Suitable for drying different materials.

3. Second waste heat recovery technology(patent)

Adopt air to air heat exchanger dehumidify and recovery waste heat at the same time, saving energy more than 40%.

4. Exact control temperature and humidity

According to different material setting different drying curve,

the heat pump dryer can control the drying

chamber temperature between 20-80℃

5. Recovery volatilized component

Some kinds of material contain volatilized component,

In drying processing,hot and wet air will become condenser water then drain,

collect the condenser water so that collect volatilized component

Recommendation

Recommend Six Kinds Of Dryer + Drying Chamber

1. One Unit JK03RD Dryer + Drying Chamber, Suitable about 300KG/Batch

2. One Unit JK06RD Dryer + Drying Chamber, Suitable about 600KG/Batch

3. One Unit JK10RD Dryer + Drying Chamber, Suitable about 1000KG/Batch

4. Two Units JK03RD Dryers + Drying Chamber, Suitable about 800KG/Batch

5. Two Units JK06RD Dryers + Drying Chamber, Suitable about 1500KG/Batch

6. Two Units JK10RD Dryers + Drying Chamber, Suitable about 2500KG/Batch

Which item do you require? Please feel free to send us your inquiry, we will reply with details such as prices list, MOQ, packaging, delivery time, payments terms etc.

why choose heat pump drying mchine ?

|

Various Drying Energy Economy Comparison Table | |||||||

| Heating Mode | Electric heating | Coal Boller | Oil-fired Boiler | Gas Boller | Biomass Stove | Regular Heat Pump dryer | LD Latest Heat Pump Dryer |

| Remove 1kg of water required heat energy | According to information provided by the relevant authority of the document, the average 1kg of water to remove heat energy required for 1.35 kw/kg,namely 4860 kj/kg | ||||||

| Fuel type | Electric | Coal | Diesel | Gas | Biomass fuels | Electric | Electric |

| Heat value | 3600 kj/kg | 23027 kj/kg | 33494 kj/kg | 36006 kj/kg | 17459 kj/kg | 3600 kj/kg | 3600 kj/kg |

| Thermal efficiency | 95% | 30% | 85% | 85% | 90% | 350% | 400% |

| Effective thermal value | 3420 kj/kg | 6906 kj/kg | 28469 kj/kg | 30605 kj/kg | 15713 kj/kg | 12600 kj/kg | 14400 kj/kg |

| Fuel price | 0.1$ /kwh | 0.1$ /kg | 1.2$ /L | 0.8$ /m3 | 0.2$ /kg | 0.1$ /kwh | 0.1$ /kwh |

| Fuel consumption | 1.42kwh | 0.7kg | 0.17L | 0.159m3 | 0.375kg | 0.386kwh | 0.337kwh |

| Fuel consumption ($) | 1.42 | 0.7 | 1.26 | 0.795 | 0.37 | 0.39 | 0.33 |

| Labor management, warehousing costs | Higher | High | High | High | Low | Low | Low |

| Safety performance | Unsafe | Unsafe | Unsafe | Unsafe | Safe | Safe | Safe |

| Environmental pollution | None | Very serious | More serious | More serious | Light pollution | None | None |

| Life of equipment | 5-8 years | 6-9 years | 6-9 years | 6-9 years | 8-12 years | 10-15 years | 10-15 years |

successful cases

Global parter

Certificate:

If you want to know more detail,please contact me:

Scan the two-dimension code watch the dehydration machine video

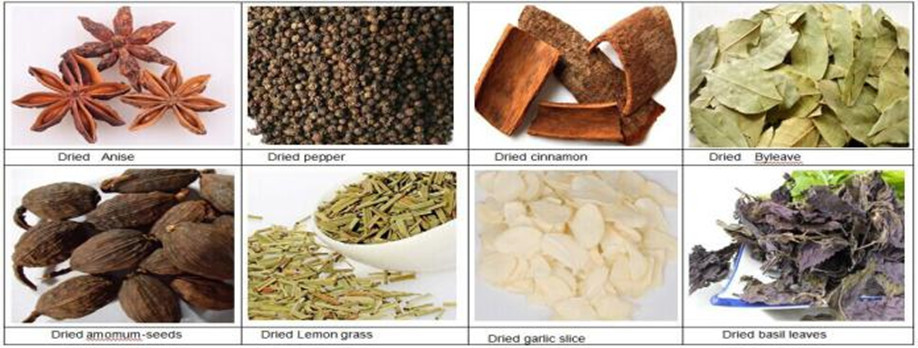

Air circulating drying chamber date drying machine/jujube dryer is suitable for heating and solidification, and dehydration of raw materials in pharmaceutical industry, chemical industry,foodstuff industry,agricultural products, aquatic products, light industry heavy industry and so on. Such as medicine of raw materials, Chinese traditional medicine, tablet of drink, powder, granule, packing bottle, pigment, dyestuff, vegetable dehydration, dried fruit and melons, sausage, plastic resin, electric elements, drying varnish and so on.

AAA1

Air circulating drying chamber date drying machine/jujube dryer is equipped with low noise axial flow fan and automatic temperature control system. The circle system is fully sealed. It makes the hot efficiency increased from 3-7% of traditional oven to nearly 40%. The maximum hot efficiency can be up to 70%. The successful design of Air circulating drying chamber date drying machine/jujube dryer makes the hot air circle oven catch up the advanced level both at home and abroad. It makes country save plenty of energy source and increase profit of enterprises.

AAA2

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: [email protected]