Why do you choose the Shandong Leader Machinery Co.,ltd. Batch Drying Type Energy Saving Heat Pump Fruit Dryer?

1.Healthy! Pure mechanical squeezing craft maximally keeps the nutrients of the oil plants.No chemical substances left

2. High working efficiency! Due to a high working efficiency of the screw oil press machinery,both time and power can be saved.

3. Long durability! All the parts are made of the most suitable material and treated with refined crafts, such as cemented quenching and tempering to increase the hardness, consequently the durability.

4. Batch Drying Type Energy Saving Heat Pump Fruit DryerCost-effective! Low investment! The wearing parts on the oil press machinery such as the squeeze loop, squeeze spiral and squeeze bar are designed to be dismountable. When they are out of service period, users only need to replace them and there is no need to displace the whole machine.

Batch Drying Type Energy Saving Heat Pump Fruit Dryer

Product Description

LD Heat Pump Fruit Dryer Introduction

Do you want to take advantage of heat in the air to dry fruits with free ?

Do you want to have an automatic controlling dryer machine?

Do you want to have an uniform drying?

LD third generation heat pump fruit dryer is a device that transfers heat from a coLDr area (ambient temperature) to a hotter area (drying chamber) by using mechanical energy,

1.Our dryer evaporator of refrigerant absorb the hot air from outside

2.then compressor works made the hot air temperature rise

3.Then heat exchanger change the hot air into drying chamber

4.final fruits will dried by the hot air circulating in drying chamber.

Features of Fruit Dryer?

1. Adopt close dehumidify + circulating drying type, saving operating cost;

Without waste gas and waste heat pollution, low noise

2. PLC + Touch Screen, operating easily; can setting different drying curve, Suitable for drying different materials.

3. Second waste heat recovery technology (patent)

Adopt air to air heat exchanger dehumidify and recovery waste heat at the same time, the heat efficiency is high and energy is saved.

4. By using the forced ventilation function, there are the adjustable air distribution plates inside the oven. The materials can be dried uniformly.

5. The temperature: hot air heating 10-75°C, max, 75°C. The temperature using the electrical: 50-90°C

6. The baking plate dimensions and materials can customize as customer request.

7. During drying, the material does not craze, does not distortions, non-discoloring, never degenerate, non-oxidize, drying completely, with good rehydration, keep nutrient content;

8. Safe and reliable operation, automatic intelligent control, 24-hour continuous drying.

Stable operation without being influenced by weather

Technical Parameters

| Model | JK03RD | JK06RD | JK10RD | |

| Power supply | V/PH/HZ | 380/3/50 or 220/1PH/50 | 380/3/50 | 380/3/50 |

| Power input | KW | 2.8 | 5.8 | 10.8 |

| Running current | A | 8/17 | 12.6 | 22.5 |

| Auxiliary electric heater(option) | KW | 9 | 9 | 9 |

| Heating capacity | KW | 12 | 26 | 35 |

| Cooling capacity | KW | 7.5 | 20 | 25 |

| Dehumidification amount | L/H | 8 | 20 | 40 |

| Max. hot air Temperature | ℃ | 75 | 75 | 75 |

| Working ambient temperature | ℃ | -10~45 | -10~45 | -10~45 |

| Noise | dB(A) | 60 | 65 | 70 |

| Fan motor for drying | Power input/unit | 250W/unit | 250W/unit | 250W/unit |

| Wind volume | m3/H | m3/H | 2500m3/H/unit | |

| Recommend qty | 8 | 8 | 16units | |

| Dimension(L*W*H) | mm | 1650*960*1280 | 1720*1160*1280 | 2100*1460*1590 |

| Net weight | Kg | 210 | 385 | 480 |

| Gross weight | Kg | 240 | 420 | 540 |

Recommend Dryer+Drying Chamber Sizes

| Item | Description | Product Capacity | Drying Chamber size |

| 1 | One unit JK03RD dryer + drying chamber | 300Kg / batch | 3300*1900*2200mm |

| 2 | One unit JK06RD dryer + drying chamber | 600Kg / batch | 6000*2800*2200mm |

| 3 | One unit JK10RD dryer + drying chamber | 1000Kg / batch | 6000*3000*2200mm |

| 4 | Two units JK03RD dryers + drying chamber | 1200Kg / batch | 7000*2200*2200mm |

| 5 | Two units JK06RD dryers + drying chamber | 1500Kg / batch | 10000*2800*2200mm |

| 6 | Two units JK10RD dryers + drying chamber | 2500Kg / batch | 10000*3000*2200mm |

Warm prompt: We can make any drying chamber sizes as your required.

Company Information

Factory and Workshop

Product Patent

Customers

Packaging & Shipping

Our Services

1) OEM service

2) Supply spare parts according to order quantity.

3)Technical support for your installation, operation and maintenance.

4) One year’s warranty, and you can pay for extended warranty.

5)Spare parts and technical support at most economic prices after the warranty

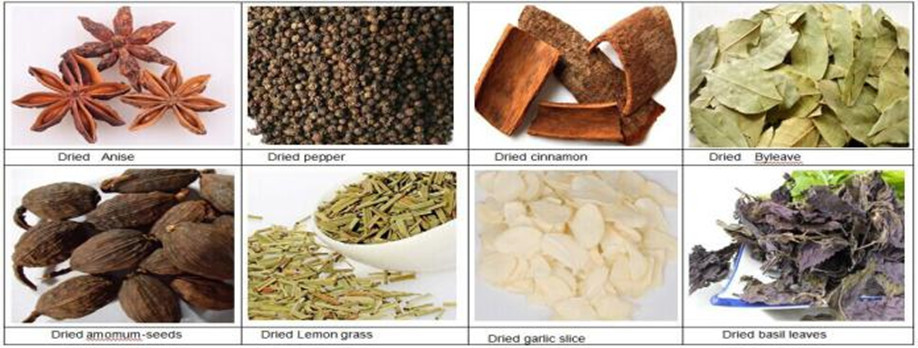

Batch Drying Type Energy Saving Heat Pump Fruit Dryer is suitable for heating and solidification, and dehydration of raw materials in pharmaceutical industry, chemical industry,foodstuff industry,agricultural products, aquatic products, light industry heavy industry and so on. Such as medicine of raw materials, Chinese traditional medicine, tablet of drink, powder, granule, packing bottle, pigment, dyestuff, vegetable dehydration, dried fruit and melons, sausage, plastic resin, electric elements, drying varnish and so on.

AAA1

Batch Drying Type Energy Saving Heat Pump Fruit Dryer is equipped with low noise axial flow fan and automatic temperature control system. The circle system is fully sealed. It makes the hot efficiency increased from 3-7% of traditional oven to nearly 40%. The maximum hot efficiency can be up to 70%. The successful design of Batch Drying Type Energy Saving Heat Pump Fruit Dryer makes the hot air circle oven catch up the advanced level both at home and abroad. It makes country save plenty of energy source and increase profit of enterprises.

AAA2

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: [email protected]