Why do you choose the Shandong Leader Machinery Co.,ltd. Industrial vegetable dehydrator machine to make dried fruits and vegetables?

1.Healthy! Pure mechanical squeezing craft maximally keeps the nutrients of the oil plants.No chemical substances left

2. High working efficiency! Due to a high working efficiency of the screw oil press machinery,both time and power can be saved.

3. Long durability! All the parts are made of the most suitable material and treated with refined crafts, such as cemented quenching and tempering to increase the hardness, consequently the durability.

4. Industrial vegetable dehydrator machine to make dried fruits and vegetablesCost-effective! Low investment! The wearing parts on the oil press machinery such as the squeeze loop, squeeze spiral and squeeze bar are designed to be dismountable. When they are out of service period, users only need to replace them and there is no need to displace the whole machine.

Industrial vegetable dehydrator machine to make dried fruits and vegetables

Product DescriptionWhat is LD heat pump dryer machine and working principle?Heat pump dryer is use of reverse Carnot principle .With free air to absorb heat and transfer it to the drying chamber, drying room temperature to achieve improved, with the appropriate humidity and dehumidification equipment to achieve dry materials. heat pump dryer Compressor - heat exchangers - Chokes - heat sink (outside the machine) - Compressor and other devices constitute a refrigerant cycle system. Under the action of the compressor in the refrigerant circulating in the system flow, it is done in the gaseous booster compressor heating process (temperature up to 100 ℃), releasing it into the machine dry in room temperature air heated by the heat, while they have been and converted to liquid cooling flow, when it runs out machines, liquid absorbs heat quickly evaporates once again transformed into a gaseous state, while the temperature dropped to minus 20 ℃ --30 ℃, then the air around the heat sink will continuously transferring heat to the refrigerant. Refrigerant continuous cycle to achieve the heat in the air transport to the drying room heating room air temperature to achieve the purpose of dry material.

LD heat pump dryer machine function:

Heating drying

Cooling drying

Heating drying + dehumidify

With traditional drying technology comparison:

1.For traditional drying technologyCurrently, most of dehydrated fruits, vegetable is still using the traditional drying methods - sun, coal, wood, and fire back to Long Road heated drying room drying method, all of them out of the following problems :

1)the drying temperature is too high. The traditional drying techniques is difficult to control the drying temperature, drying temperatures are generally around 75-90 ℃, and dehydrated fruits and vegetables drying process requires drying temperature should not exceed 65 ℃.

2)the drying time is too long. Conventional drying technology, each processing one ton of vegetables need at least more than 24h, sometimes due to the drying effect is not good to be reworked, the time required for longer.

3)power-hungry. Conventional drying technology, thermal efficiency are low, about 30% -60%, in the drying process, accounting for about 36% of the dry heat of vaporization of water, accounting for about 58% of the exhaust gas losses, take the heat and dry materials dryer heat loss accounted for 2% and 2%, respectively, the thermal efficiency of only 40%.

2.For Heat pump drying technology

1, the drying temperature is low. Heat pump drying technology production processes around 38-52 ℃ lower than conventional drying techniques, namely the heat pump heating and drying technology temperature around 37 ℃ -65 ℃.

Our Heat pump dryer model for clients choose:

NEW TYPE HEAT PUMP DRYER MODEL | |||||||

Items |

Unit |

JK03RD |

JK06RD |

JK10RD |

JK12RD |

||

Production capacity |

1set |

300kg |

600kg |

1000kg |

1200kg |

||

2 sets |

600kg |

1200kg |

2000kg |

2500kg |

|||

Suitable drying chamber size |

M3 |

10-30 |

30-40 |

40-50 |

60-70 |

||

Heating capacity |

Kw/h |

12 |

26 |

35 |

42 |

||

Cooling capacity |

Kw/h |

7.5 |

15 |

25 |

30 |

||

Dehumidification amount |

L/H |

10 |

25 |

50 |

60 |

||

|

Input power

|

Compressor |

kw |

2.8 |

5.3 |

9.3 |

11.2 |

|

Evaporator fan motors |

0.78 |

0.78 |

1.5 |

1.5 |

|||

Hot air circulating fan |

2 |

2 |

2 |

2 |

|||

Dehumidify fan motor |

0.37 |

0.37 |

0.55 |

0.55 |

|||

Auxiliary electric heater |

3 |

6 |

9 |

9 |

|||

Power supply |

kw |

220v/380v |

380v/3ph/50hz or 60hz |

||||

Total running current |

A |

35/20 |

30 |

45 |

45 |

||

Max hot air temperature |

℃ |

75 |

|||||

Min cooling temperature |

℃ |

8 |

|||||

Working ambient temperature |

℃ |

-10-45 |

|||||

Mixture Refrigerant |

kg |

2.5 |

4.5 |

8 |

9.75 |

||

Weight |

kg |

210 |

385 |

480 |

500 |

||

|

Dimension |

length |

mm |

1650 |

1730 |

2100 |

2179 |

|

Width |

960 |

1220 |

1460 |

1356 |

|||

Height |

1280 |

1280 |

1590 |

1930 |

|||

FOB Guangzhou price |

USD |

|

|

|

|||

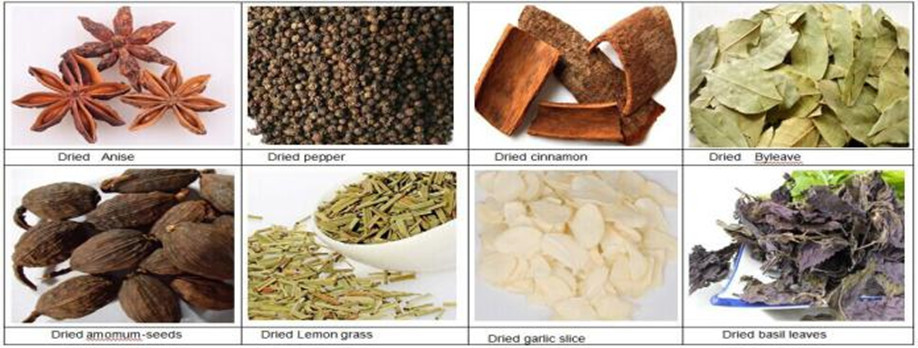

Our dried fruits &vegetables&fishes &meat projects:

Our service and shipment:

A. Payment service

1, T/T

2, L/C (for container order only)

3, Western Union, (for sample order & parts)

B. Technical service

1, We calculate the capacity and recommend the models.

2, We supply you the professional refrigeration technical support and electronic technical support for your installation, debugging and operation.

3, We supply the spare parts and technical support in & after the warranty time.

4, We supply the training course to your workers at our factory if you need.

C. After-sales service

1, Technical support for your installation, operation and maintenance.

2, One year’s warranty, and you can pay for extended warranty.

3, Spare parts and technical support at most economic prices after the warranty.

Industrial vegetable dehydrator machine to make dried fruits and vegetables is suitable for heating and solidification, and dehydration of raw materials in pharmaceutical industry, chemical industry,foodstuff industry,agricultural products, aquatic products, light industry heavy industry and so on. Such as medicine of raw materials, Chinese traditional medicine, tablet of drink, powder, granule, packing bottle, pigment, dyestuff, vegetable dehydration, dried fruit and melons, sausage, plastic resin, electric elements, drying varnish and so on.

AAA1

Industrial vegetable dehydrator machine to make dried fruits and vegetables is equipped with low noise axial flow fan and automatic temperature control system. The circle system is fully sealed. It makes the hot efficiency increased from 3-7% of traditional oven to nearly 40%. The maximum hot efficiency can be up to 70%. The successful design of Industrial vegetable dehydrator machine to make dried fruits and vegetables makes the hot air circle oven catch up the advanced level both at home and abroad. It makes country save plenty of energy source and increase profit of enterprises.

AAA2

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: [email protected]