High Efficient Buckwheat Husk Buckwheat Hulling Machine

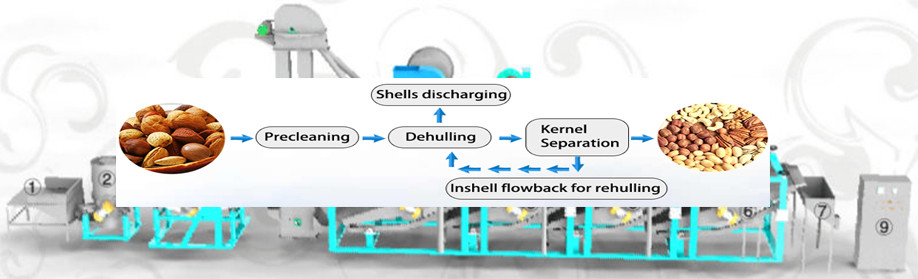

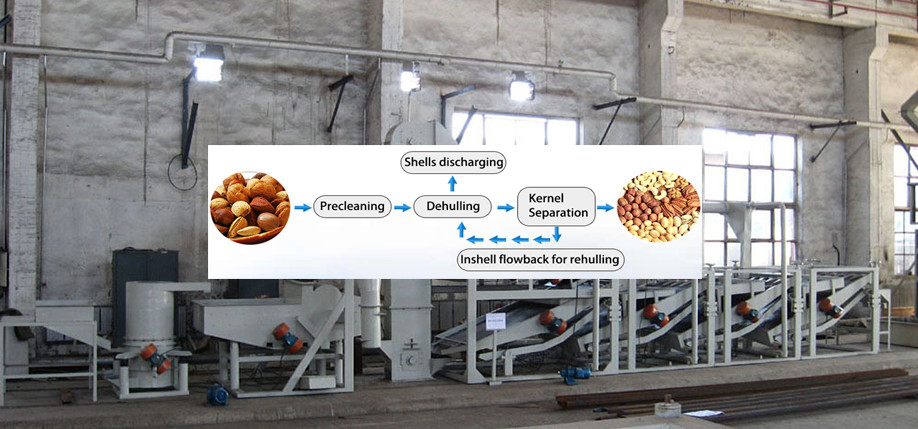

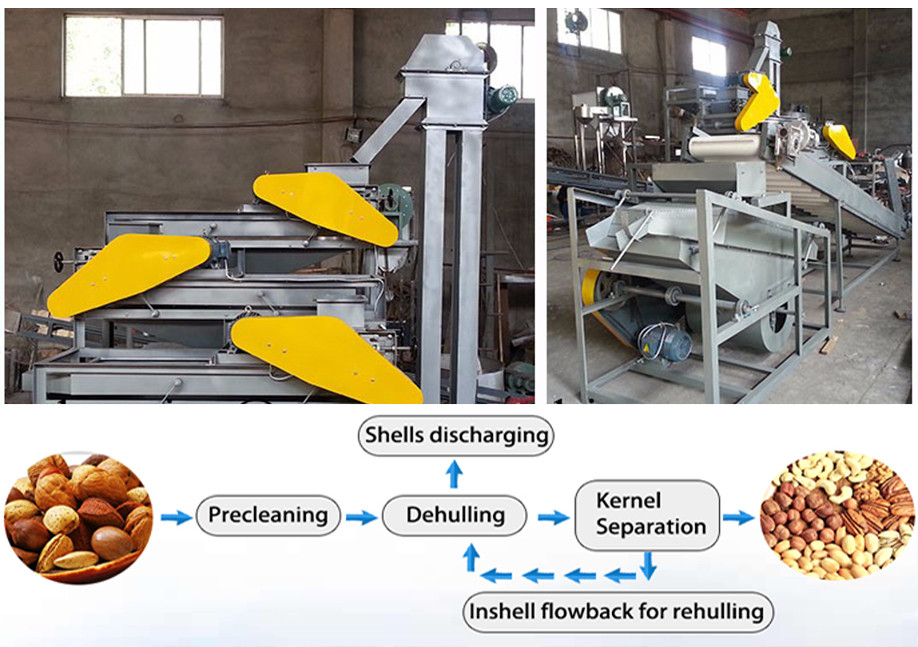

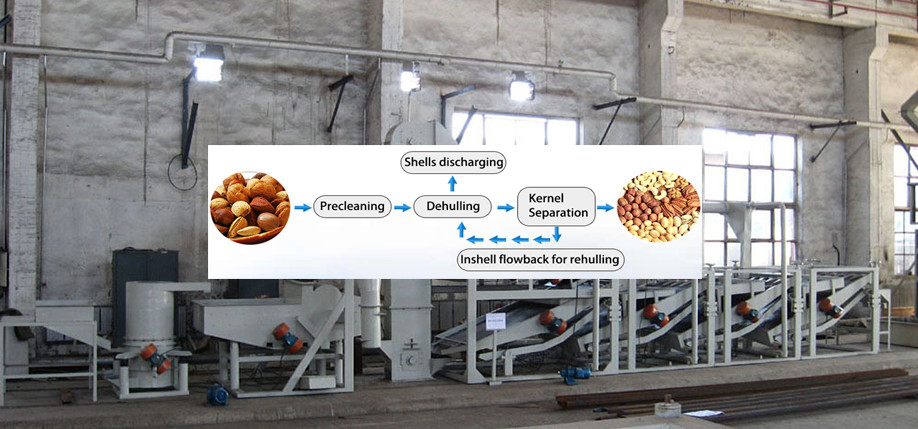

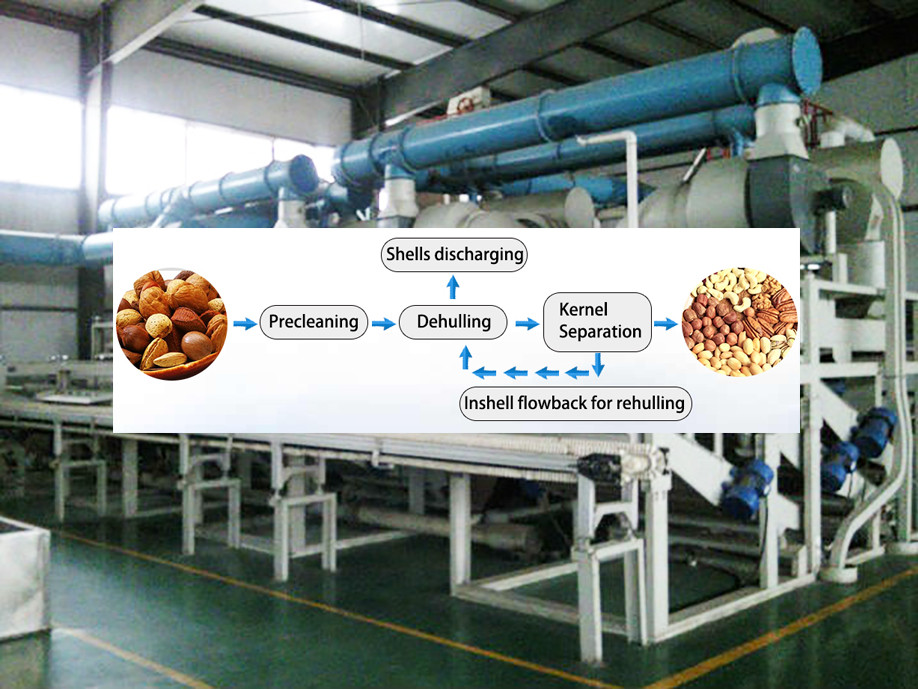

Product DescriptionBuckwheat huller working process:

It has high hulling ratio with less broken rate; Clearance between emery roll can be adjusted, which ensures the effect of hulling ratio.

Buckwheat raw materials should be processed by cleaning and classifying before shelling. The mudstone, soil, large and small impurities is removed first by multifunctional shaker. Then the material is conveyed to the classifying screen by bucket elevator for classifying. After this, it can enter into the buckwheat shelling machine.

Buckwheat huller is equipped with two emery rollers (lower and upper roller). When the raw material flows into the husking chamber, the high-speed rotating emery rollers cut and rub the buckwheat cortex continuously, which destroys the bonding strength between buckwheat shell and kernels. In this way, buckwheat husk is removed. After hulling, the buckwheat is processed by windmill screen, then enters into classifying screen. By vibrating and sorting, the buckwheat kernels and husks are separated and then the finished products are packaged. The unhulled buckwheat is sent back to the huller for continuous shelling.

Technical data of buckwheat huller machine:

New designed Small Grain Hulling Machine Buckwheat Hulling Machine is a main product of our company. Also it is the most widely used with better hulling result in the world. During the hulling process, the buckwheat kernel-shell can be separated automatically at the same time, and meanwhile sort out the brokens from kernels. It adopts dry method hulling process, no preheating to buckwheat required beforehand.

Small Grain Hulling Machine Buckwheat Hulling Machine Working Principle:

The raw buckwheat has to be cleaned and graded before husking. The machine equips with two emery rollers (lower and upper roller). When the raw material flow into the husking chamber, the high-speed rotating emery rollers cut and rubs to remove outer shell.

Features of Small Grain Hulling Machine Buckwheat Hulling Machine:

1. High husking rate, low breakage, full kernels

2. Adjustable roller gap ensures the best husking performance

3. High throughput, reliable quality, stable and sturdy construction thank to unity design, low noise, environmental friendly

4.This series of machines are the best buckwheat husker in the world, apply to formulate of package unit in the buckwheat fine and further processing plant.

Final products of Small Grain Hulling Machine Buckwheat Hulling Machine:

Packaging & Shipping

Packaging & Shipping

Company Information

Company InformationELDibition

Certifications

Contact Us

Contact Us

Shandong Microwave Machinery Co.,Ltd.is a Buckwheat Dehulling Machine factory specializing in the production of High Efficient Buckwheat Husk Buckwheat Hulling Machine, scientific research, manufacturing,installation, commissioning.Shandong Microwave Machinery Co.,Ltd.can provide Buckwheat Dehulling Machinecustomers with design and services of 1-2000 tons High Efficient Buckwheat Husk Buckwheat Hulling Machine. Shandong Microwave Machinery Co.,Ltd. have finished hundreds of successful projects Buckwheat Dehulling Machineover the years: peanut oil, soybean oil, rapeseed oil,cottonseed oil, sunflower oil, sesame oil, animal oil,grape seed oil, acer truncatum oil, peony seed oil, walnut oil, hemp seed oil, pine oil, tea seed oil, papaya oil, milk thistle seed, and other special type Buckwheat Dehulling Machineoil. Shandong Microwave Machinery Co.,Ltd. have independent import and export department. Shandong Microwave Machinery Co.,Ltd. Buckwheat Dehulling Machineequipment has been successfully exported to more than ten

countries: Russia, Australia, India, Afghanistan, Cameroon,and so on.

Carrie

Shandong Microwave Machinery Co.,Ltd.

Email: [email protected]

Skype:leaderfoodmachine10

Web: www.epier.com Moblie:0086-15020017267( WhatsApp)