QMTP Buckwheat Husker/ Sheller/Hulling Machine

Product Description

Types

QMTP-300

FEATURES

This machine is our patented product based on advanced Japanese technology;

High husking rate, low breakage, full kernels;

High throughput, reliable quality, stable and sturdy construction thank to unity design, low noise, environmental friendly;

Adjustable Roller gap ensures the best husking performance.

FUNCTIONAL DESCRIPTION

The raw buckwheat has to be cleaned and graded before husking. The machine equips with two emery rollers (lower and upper roller). When the raw material flow into the husking chamber, the high-speed rotating emery rollers cut and rubs, the corn cortex continuously, which destroys the bonding strength between maize endosperm and embryo? In this way, buckwheat husk is removed.

The machine is an ideal equipment for the removal of buckwheat husk. It serves as an essential element in the buckwheat intensive processing plants.

TECHNICAL PARAMETER

Type |

Capacity |

Power |

Rated Voltage |

Temp |

Roller Specification |

Speed |

Weight (KG) |

Size |

|

(KG/H) |

(KW) |

(V) |

(°C) |

(MM) |

|||||

QMTP-300 |

200-300 |

1.1-2.2 |

380 |

10~50 |

Φ300*30 |

975 |

250 |

850*570*1300 |

|

QMTP-600 |

500-600 |

3~4 |

380 |

10~50 |

Φ600*60 |

950 |

960 |

1580*1100*1600 |

National Patent No.: one kind of buckwheat husker ZL 2010 2 0689475.3

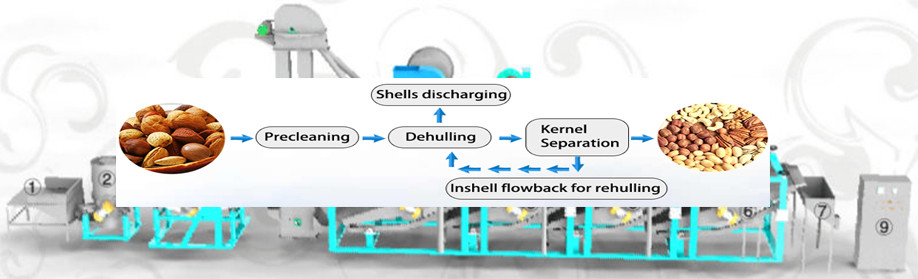

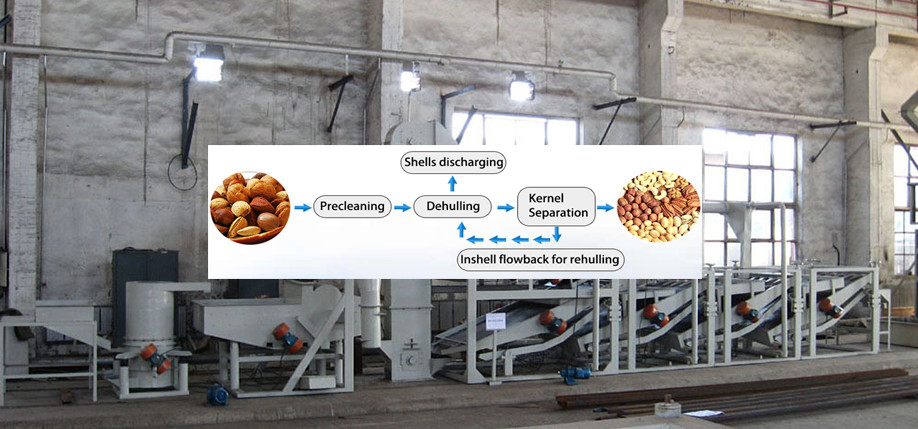

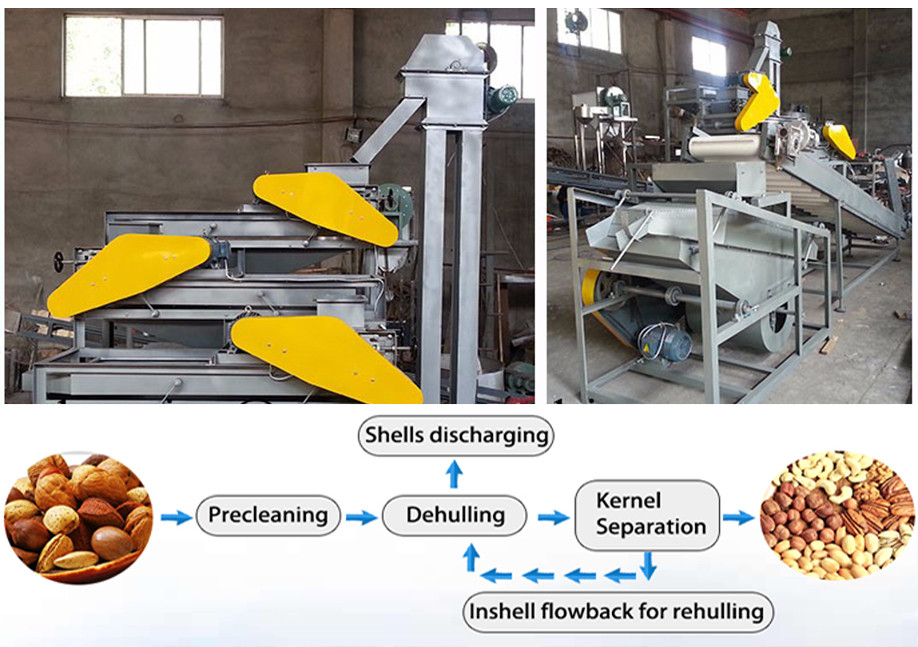

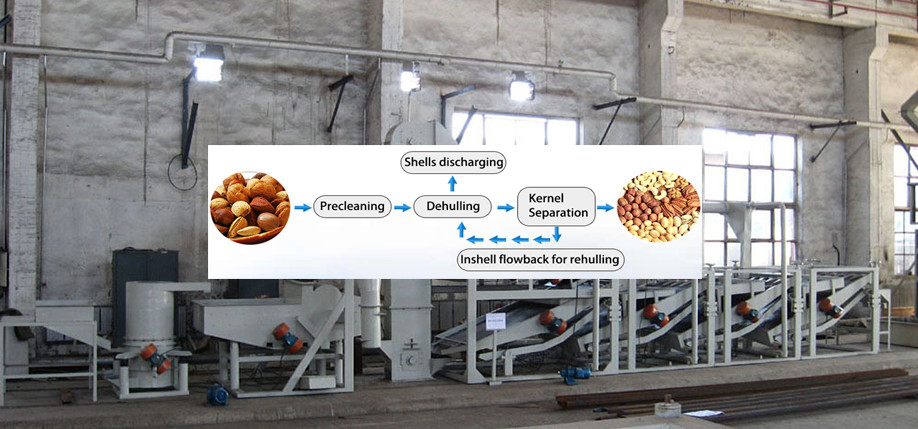

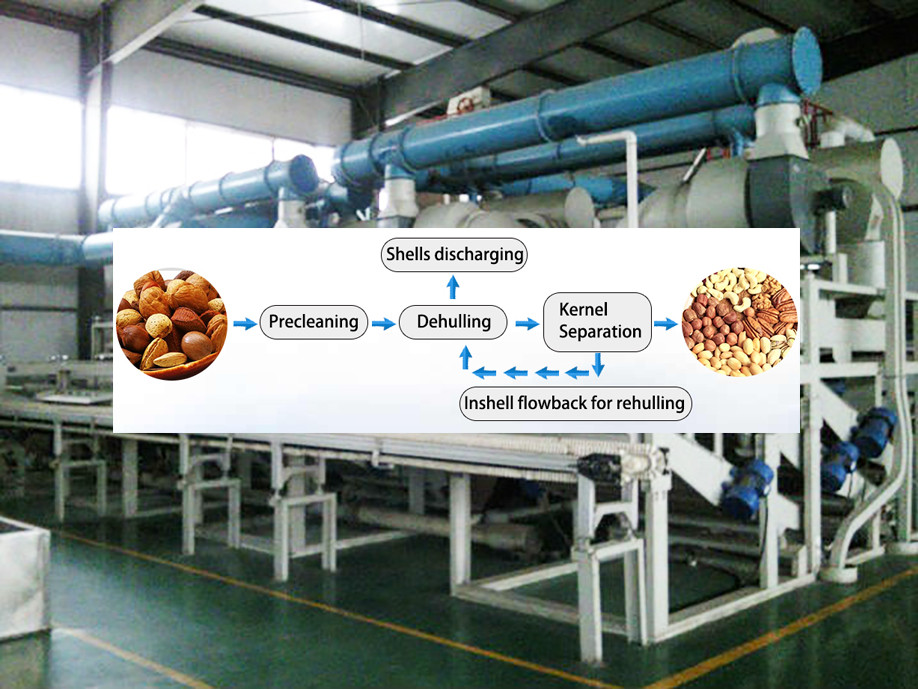

Husker Process

LD Machinery Manufacturing Company Ltd., Lushan, Henan Province (or LD), was established in 1995. It owns total assets of 53,600 thousand RMB with 230 staff including 50 professional technicians and 20 engineers. Engineers with the college degree take up more than 60% of the total staff number. The company has new modern standard workshop of 66,000 centare, which owns first class coarse grain processing and manufacturing equipments. The manufacturing capacity of the coarse cereal processing equipments industrialization has occupied the domestic leading level. It is a high-tech machinery manufacturing enterprise which specializes in corn and coarse grain primary, fine and deep processing and integrates in research, production and sales.

LD lead through ISO9001:2000 international quality system certification and achieved more than 20 new practical products patents. We commit ourselves to forming into the leading enterprise with the best and most competitive benefit and brand.

Located in Lushan, we serve our customers both home and abroad. We have 300 sales agencies. Our products are popular in over 30 provinces and cities in China and also exported to more than 40 countries and areas in Latin America, Afica and Southeast Asia. We open 400 service hotlines, provide technical service whenever and wherever and test the customers' equipments conditions in time. Meantime, LD has a modern manufacturing headquarters base, a corn and coarse grain engineering technology center, an international business center and a precision casting company, which can control the processing procedure strictly and supply for the processing technology research. We also can produce and design according to customers' different needs and provide them with the complete engineering solutions of the high-end products.

Business Type:Manufacturer, Trading Company

Main Products:Grain Processing Machinery (Corn & Coarse Cereals Complete Equipment,Corn & Coarse Cereals Single Equipment)

Location:Shandong

Year Established:2006

Number Of Employees:201 - 300 People

Total Annual Sales Volume:confidential

Main Markets:Domestic Market, Africa, South America, Southeast Asia, North America

Product Certifications:Chinese Famous Bran,Chinese Famous Product

Average Lead Time:30 Day(s)

Project

Main Business Scope:

1. large, medium, small dry and semi-dry corn germ extracting and coarse grain deep &fine processing machinery and turnkey projects.

2. Corn/maize processing: complete equipment for corn milling , germ removing, germ selection , grits (larger, medium and small size) with 20-2000 tons per day. Deep processing of corn/maize: corn Pearl Rice, corn high gluten flour, corn dumpling flour, corn noodle flour, fine corn flour.

3. Complete equipment for old flour mill renovation and corn fine processing series with 5-2000 tons;

4. Millet & sorghum Processing Line with 5 tons -10000 tons;

And all of the single equipment series used in complete production line or separately.

Packaging & Shipping

We will pack by the protect film inner, water-repellent plastic outside. The wood packing is necessary if send by less than a container. The machine will fixed by steel rope in the container. Make sure it is in good condition when arrived destination.

ELDibition

Certifications

Certifications

Contact Us

Contact Us

Shandong Microwave Machinery Co.,Ltd.is a Buckwheat Dehulling Machine factory specializing in the production of QMTP Buckwheat Husker/ Sheller/Hulling Machine, scientific research, manufacturing,installation, commissioning.Shandong Microwave Machinery Co.,Ltd.can provide Buckwheat Dehulling Machinecustomers with design and services of 1-2000 tons QMTP Buckwheat Husker/ Sheller/Hulling Machine. Shandong Microwave Machinery Co.,Ltd. have finished hundreds of successful projects Buckwheat Dehulling Machineover the years: peanut oil, soybean oil, rapeseed oil,cottonseed oil, sunflower oil, sesame oil, animal oil,grape seed oil, acer truncatum oil, peony seed oil, walnut oil, hemp seed oil, pine oil, tea seed oil, papaya oil, milk thistle seed, and other special type Buckwheat Dehulling Machineoil. Shandong Microwave Machinery Co.,Ltd. have independent import and export department. Shandong Microwave Machinery Co.,Ltd. Buckwheat Dehulling Machineequipment has been successfully exported to more than ten

countries: Russia, Australia, India, Afghanistan, Cameroon,and so on.

Carrie

Shandong Microwave Machinery Co.,Ltd.

Email: [email protected]

Skype:leaderfoodmachine10

Web: www.epier.com Moblie:0086-15020017267( WhatsApp)