Product Description

Continuous tunnel Microwave LD machine for marsh marigold

Features:

1.Fast heating speed: directly heat on the internal and external of material at the same time, do not need to preheat. While there must be a preheating process in the traditional production.

2. Heating evenly: microwave drying is completed through electromagnetic waves produced by magnetron.The internal and external of material will be heated at the same time .

3. Less nutrition loss: material just stay in the microwave heating box for a short time, and do not need air and steam to conduct heat, therefore can maximize keep nutrients in the material.

4. Sterilization and alcoholization:The microwave drying equipment also have sterilizing and alcoholizing function.

5. Reduce the labor intensity, improve work efficiency

6. Friendly environment equipment

7.PLC automatic control can realize the data storage, output, printing.

8.Using non-contact infrared temperature measurement technoloLD, high precision, simple control.

9.Compliance with national GMP certification requirements.

Application:

Microwave to dry chemical material, usable range can be used in the iron ore class (limonite, magnetite, hematite, ilmenite, vanadium titanium magnetite, ferrous sulfide nickel, pyrrhotite and pyrite, pyrite, pyrite magnets, etc.), copper (chalcopyrite, bornite, tetrahedrite, cuprous oxide, copper oxide), manganese (soft manganese ore, manganese ore, manganese ore, manganese carbonate, etc.), lead, antimony class (galena, push lead antimony sulfur, etc.) aluminum class (such as diaspore, soft diaspore, sanshui diaspore monohydrate) and other kinds of mineral rapid drying.

Mechanical system:

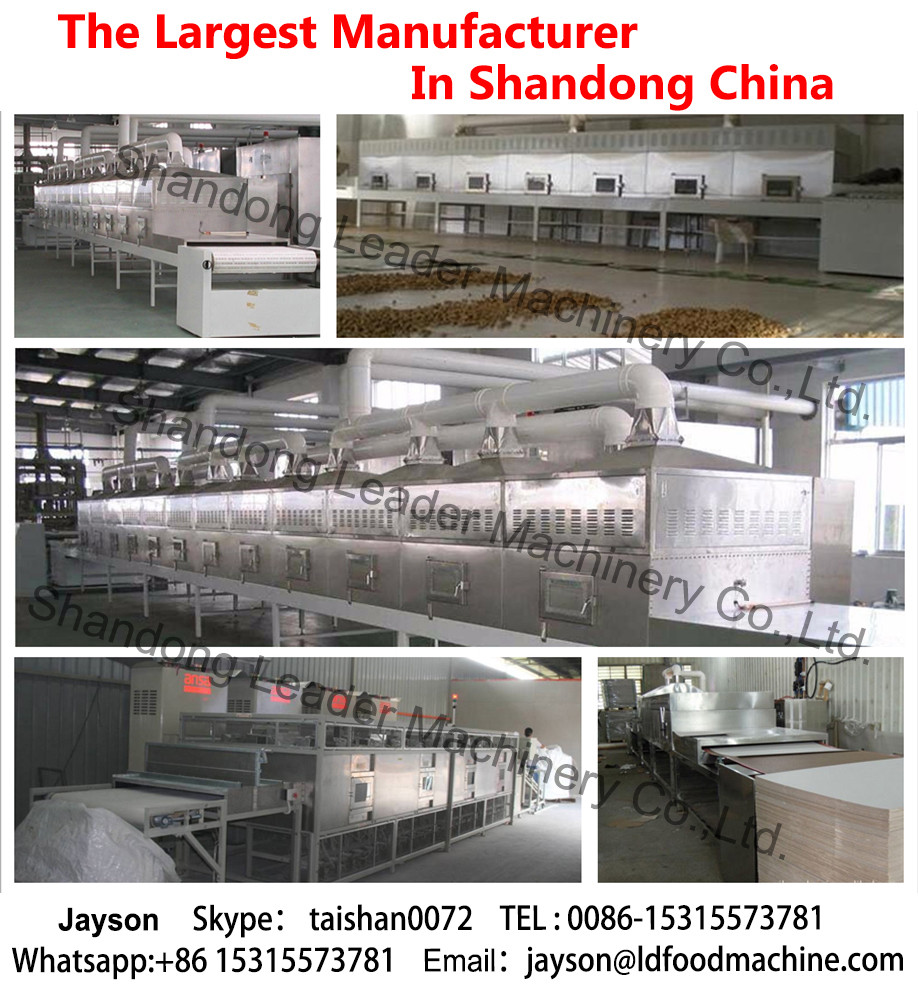

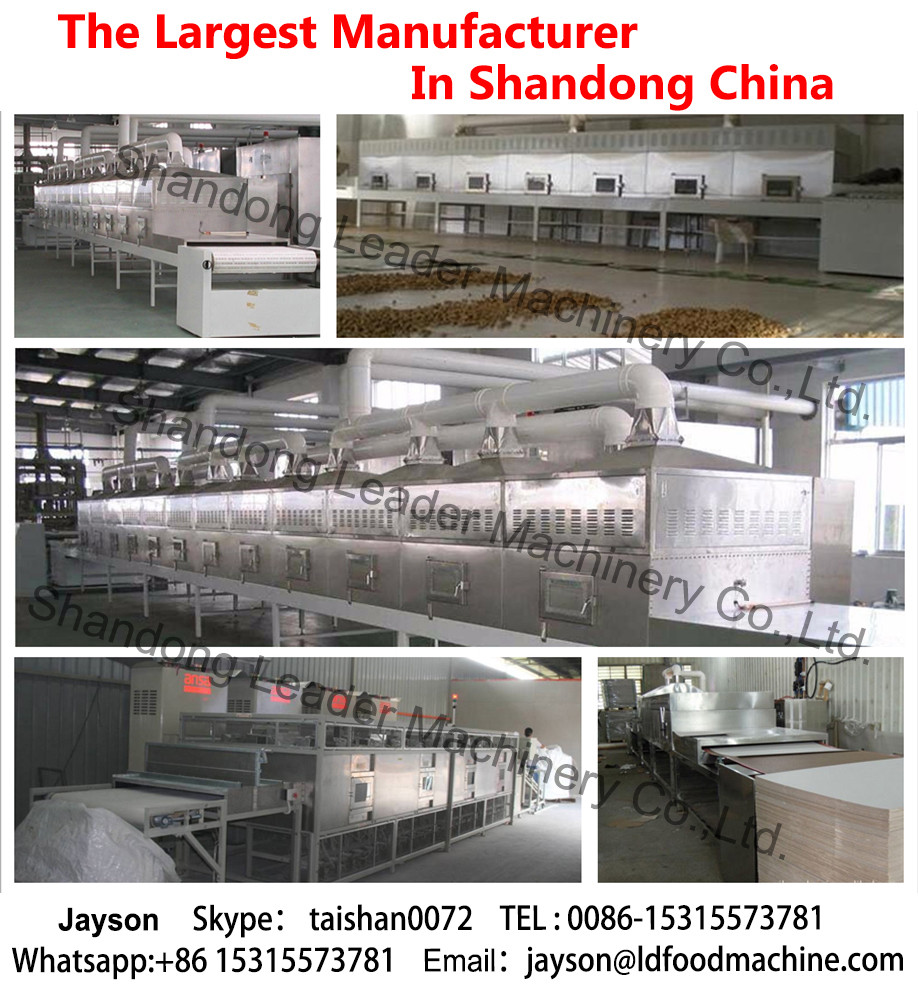

Detailed Images

Technical Parameters

| Model | Power/kw | Demension/m | Frequency/MHZ | Total weigLD/kg |

Microwave leakage (mW/cm²) |

| GRT-P15 | 15 | 6*1.1*1.7 | 2450±50 | 1000 | ≤5 |

| GRT-P20 | 20 | 8*1.1*1.8 | 1200 | ||

| GRT-P30 | 30 | 10*1.1*1.8 | 1300 | ||

| GRT-P50 | 50 | 12*1.1*1.8 | 1500 | ||

| GRT-P80 | 80 | 14*1.1*1.8 | 2200 | ||

| GRT-P100 | 100 | 16*1.1*1.8 | 2500 |

Advantages

Compared with conventional drying methods, which are heating from the outside to the inside by heat conduction, microwave show so-called volume heating with the following advantages:

1, temperature gradient directed towards the surface, i.e. temperatures inside are higher than outside, giving rise to a higher partial pressure that drives the evaporating liquid to the surface consequently, the superficial layer does not dry up completely and the surfaces remain permeable.

2, the liquid evaporating inside the product is emitted through the porous structure of the solid material’s macro-capillary system, resulting in a high drying velocity.

3, the heating of water and most organic solvents occurs selectively - due to the LDer dielectric losses of water as compared to the product to be dried.

4, swift and thorough drying of moist products with low thermal conductivity static drying of thick layers without frictional losses.

5, high total efficiency of enerLD application and high-speed control of the enerLD transport.

6,short processing times, i.e. suitable for automated manufacturing.

The DRYING MACHINE will be packed in wooden case or as your request.It will be delivered by air,international express or by sea!Good package will assure you received the goods in good condition!

Webstie:LDtp://www.LDmachineryequipment.com/

Hot line: 0086-371- 60206811

Fax: 0086-371- 60206811

Skype: sale1-LDmachinery

whatsapp/mob:0086 15639056973

If you have any need or questions welcome contact us,it is always a pleasure to offer our future cooperation!We will reply your inquiry within 24 hours!

Shandong LD Machinery equipment company

Shandong LD Machinery equipment company is dedicated to securing the progression of high quality drying machine and food processing machine for the benefit of all customers. 2007 sees the company growth and its business scope enlarge from only electronic products and small food processing machine to drying machine and some other new food processing machine.

Shandong LD machinery Equipment Company is a integration of high-tec research, production, sales and service with total investment of 5 hundred million located in High-tec development zone in Shandong city. We mainly supply a whole production chain of closely related machines, including, cleaning machine, stripping machine, drying machine and packing machine ,with the objective of fully service customer,save time and enerLD for customer and supply high quality products with competitive price.

Our company enacts our vision and values, and we naturally apply them in everything we do - including above all else our products andservice as well as the way we work with our staff, clients, suppliers etc.