Packaging & Shipping

1, Packaging Details: one Industrial tunnel Microwave LD/microwave drying machine is fit for a 40GP.

2, Delivery Detail: One Industrial tunnel Microwave LD/microwave drying machine needs 20 days, two Microwave LDs 30-40 days.

Product Description

continuous microwave drying machine/dehydrator for fruits and vegetables

Features of continuous microwave drying machine/dehydrator for fruits and vegetables :

1) Machine material: food-grade SUS304 stainless steel

2) EnerLD-saving more than 30%

3) High production efficiency

4) Safety and easy clear.

5) Improve working conditions: PLC touch screen control, automatically operation

6) The device control host environment temperature: seasonal normal temperature, environment relative humidity is less than 85RH.

7) Equipment body (microwave generating source part): Non corrosive gases, flammable, explosive gas around, environment temperature is 0-38 ℃environmental relative humidity is lower than 85RH

8) Site requirements(L*W*H): 10m*3m* 3m

9) It is suitable for the deep drying of many material with drying and sterilization, such as, bean, corn, rice, ground peanut, etc.

10) The equipment which need user provided : The pipeline from the fan to the outside, drainage fan, The standby power supply, power line, transformer. Cooling oil and etc.

The working principle of continuous microwave drying machine/dehydrator for fruits and vegetables :

microwave is issued by the microwave generator, formed a strong magnetic field in the microwave sterilization cavity. The water molecules in the material produced high speed reciprocating motion by the polarity change in the magnetic field, friction heat, and then for the purpose of sterilization.

The circuit control system of continuous microwave drying machine/dehydrator for fruits and vegetables:

1, Control modes:

PLC control, man-machine interface operation, high automation degree.

The console is arranged in the feeding end equipment, using PLC and image monitoring technoloLD(monitoring points: intermediate operating cavity), realized the visualization of the drying process. Withpreventing microwave leakage detection device can realize the automatic alarm function.

2, Power control:

Packet control microwave system, achieved a high degree of automation and humanization ideaindustrial microwave equipment according to set program automatic adjustment output microwaveintensity;

3, Temperature control:

Using the real-time temperature measuring precision in the drying process, according to the settemperature requirements, automatic regulated microwave field strength. Configure automatic smokesensing device, overheat burning , automatic shutdown. realized the process requirements andequipment self protection function;

4, Variable frequency speed regulation:

The transmission speed variable frequency adjustable, adjusted the LD effect by combining thematerial properties and microwave intensity. Implanted into the automation program, realized theautomatic operation. Not only can improve the product quality, but also can save the manpower cost.

Technical Parameters

| Modle | Type | Frequency(MHz) | Power supply | Power(Kw) | Size(L*W*H)m | Microwave leakage(mW/cm2) |

| GRT-C-50 | Continuous | 2450 ±50 | 380V,50Hz | 50 | 16*1.1*1.6 | ≤1 |

| GRT-C-100 | Continuous | 2450 ±50 | 380V,50Hz | 100 | 20*1.1*1.8 | ≤1 |

Other application of high efficiency Microwave LD/microwave drying machine/sterilizator :

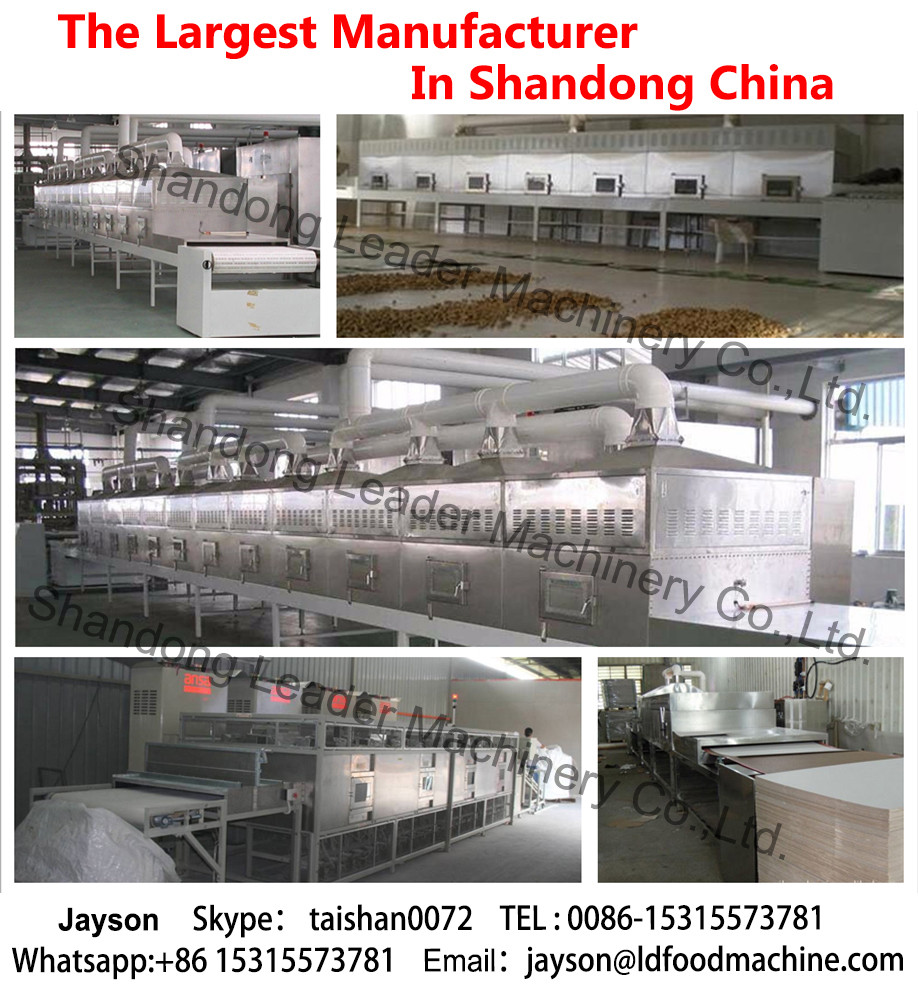

Company Information

Shandong Leader Machinery Co.,Ltd. As a leading manufacturer and supplier of a variety of microwave drying equipment and heating solutions used in different applications and industries. We provide all of the resources needed to support industrial microwave and Microwave LD circulation drying equipment and system. Our main products includes microwave vacuum Microwave LD, Microwave LD circulation drying oven, batch Microwave LD, digital displayed constant temperature drying machine,etc.

Our mission is to increase our customers' business productivity while assuring operator safety by helping users realize the maximum benefit from the quality of equipment, human resource, technoloLD and general processes. This is accomplished in the design and manufacturing of equipment and support components at a level of quality unsurpassed in the industry.

Our Services1. Pre-sale services:

Our Services1. Pre-sale services:Assistant of clients enable them to get rich and generous returns on their investments.

Select machine model;Design and manufacture according to clients' special requirement;

Train technical personnel for clients.

2. Services during the sale:

Pre-check and accept machine ahead of delivery;

Help clients to draft solving scheme .

3. After-sale services:

Provide considerate services to minimize clients' worries.

Assist clients to prepare for the first construction scheme;

Install and debug the equipment;

Train the first-line operators;

Examine the equipment;

Take initiative to eliminate the troubles rapidly;

Provide perfect service..

ZOE / Sales Manager Shandong Leader Machinery Co.,Ltd.Mobile: +86 -15106913958whatsapp:+86 +86 -15106913958wechat:+86 -15106913958Skype: ZOEweb: www.LDmachinery.en.alibaba.com www.LDmachineryequipment.com Add: NO.11,Changchun Road,High-tech Development Zone, Shandong, China Please send an message to us if you want to receive the more details, we will feedback you within 12 hours.

ZOE / Sales Manager Shandong Leader Machinery Co.,Ltd.Mobile: +86 -15106913958whatsapp:+86 +86 -15106913958wechat:+86 -15106913958Skype: ZOEweb: www.LDmachinery.en.alibaba.com www.LDmachineryequipment.com Add: NO.11,Changchun Road,High-tech Development Zone, Shandong, China Please send an message to us if you want to receive the more details, we will feedback you within 12 hours.