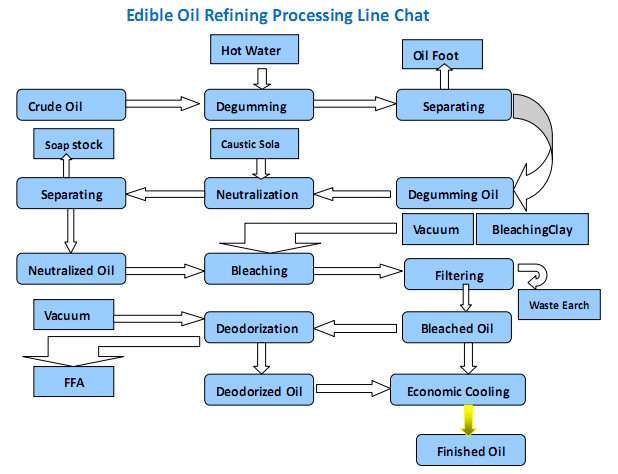

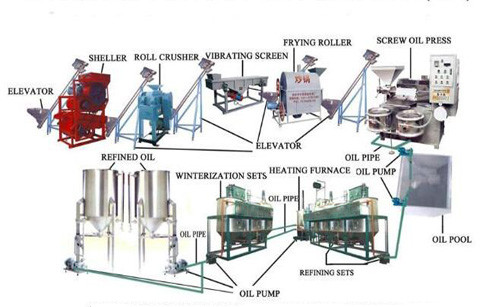

The objective of 1-20TPD Small Scale Oil Refining Line refining is to remove objectionable co-constituents in oil with the least possible damage to glycerides and minimal loss of desirable constituents 1-20TPD Small Scale Oil Refining Line. Ways of refining depend on nature and quantity of impurities contained in crude oil, application of RBD oil.Shandong Leader Machinery Co.,ltd. Classical chemical refining is used through successive steps: it must be degumming, neutralizing, bleaching, deodorizing and sometimes winterizing (Mainly removing free fatty acid and other minor constituents).The set of equipment has obtained national patent (patent No. is ZL99 25288.7), hydraulic oil press/ hydraulic rapeseed oil press machine / Hydraulic Walnuts oil is our developed third generation product with more advanced and mature technology, and it won GoldMedal on 8th China Fair of Inventions and New Technologies and Silver Medal on 6th International Invention Exhibition. 1-20TPD Small Scale Oil Refining Line adopts intermittent refining craft, and has advantages of convenient transportation, small covering area, less operation staff and saving energy.

Product Description

automatic hydraulic oil press

rapeseed oil press machine

6YY-230,260 auto quick hydraulic oil press , is of the same products abroad in introducing based on improved design becomes.The mchine is specialized wrung sesame,walnuts,almonds,waittil raw materials,machinery,simple operation,convenient haracteristicof high,each pack 6-8kg material,8-10minutes wrung net.

product feature

1: Which can press sesame, walnuts, almonds, and other high oil crops.

2: This is machine is very suitable for family using and small scale oil factories

3: After pressed, the oil is very pure with good smell, can be edible for people directly

4: It is durable using, which is the least to change the wearing parts

5: It is made of stainless steel, so the oil can reach the healthy standard. Which is do good to people health.

The structure of the hydraulic oil press

This machine is mainly composed of three parts :

1. The main body. 2. Hydraulic transmission. 3. The electric control

1. The main body part :

It is composed of a bottom plate, column, roof, chamber assembly , oil pan, nut and other parts, Is the machine's main One of the body.The oil in the chamber assembly , by pushing up the power of the oil cylinder assembly ,oil shed from the chamber Oil flow seam , flowing through the oil pans to oil storage barrels .

2. Drive hydraulic parts:

This is the main work of this machine is high oil production rate power source , It is by the transmission shaft, worm gear, worm, gear pump, high pressure pump, relief valve, manual valve, oil cylinder assembly, pipe joints and other parts

3. The electrical control part:

This is the machine is advanced, it is composed of motor, voltage meter, temperature control regulation table, pressure gauge, power supply, insurance and other parts.

How to operate?

The oil materials among screw threads are propelled forward when the pressing screw rotates. The space between pressing chamber and pressing screw is gradually reduced, and the oil material density increases, so the pressure is gradually increasing. For the friction of oil material particles, oil material and machine parts, it generates heat. The pressure and heat breaks the oil material histiocytes, the oil overflows from the oil lines. And the oil cakes are propelled out from the cake head and cake mouth. The vacuum pump pumps out the air from the bucket when the overflowing oil flows through the oil plate onto the oil bucket. Negative pressure forms in the bucket, so the oil is pumped into the bucket through the filter cloth. The oil residues are staying on the filter cloth, thus the oil is pure

Customer site operation

why choose us

1: Steel materials of the machine are purchased from the steel manufacturering factories directly, so the materials are in high quality

2: We have top engineer group and long-term cooperation with several research institutions,

3: Our workers are professional, each of them has been trained strictly before their job;

4: We supply the high grade, the consummation after-sale service.

Visit customers

We only show the customer agrees to show photos .

Packaging & Shipping

We will be responsible for all the way to the end, until the complete product to your hands

Our Services

. Fault handing in 24 hours

- Life-long technical service and maintenance

- Spare parts supplement

- Engineer on site operation available

If you have any question ,please contact me

.

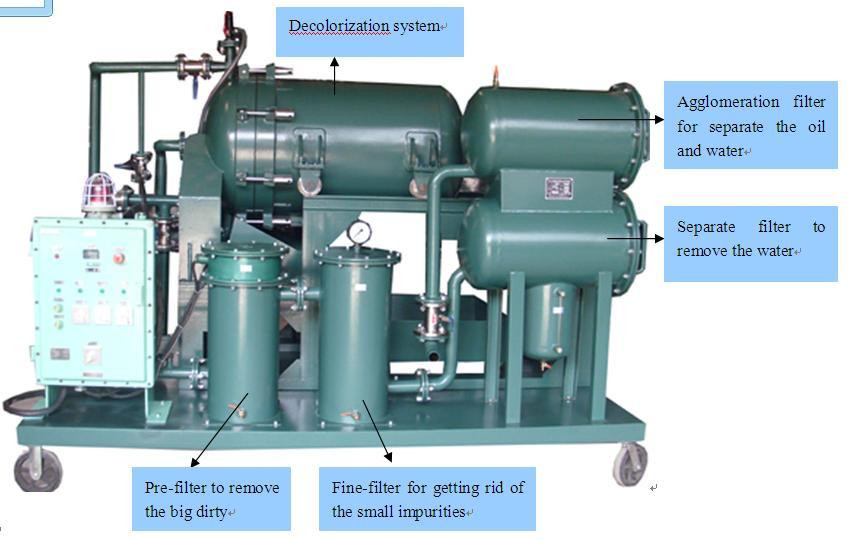

The purpose of 1-20TPD Small Scale Oil Refining Line degumming is to remove impurities such as phospholipids, gums and proteins etc. Shandong Leader Machinery Co.,ltd. are several methods as follows: water degumming, acid degumming, special degumming etc. Bleaching is the process operation which hydraulic oil press/ hydraulic rapeseed oil press machine / Hydraulic Walnuts oil removes colouring matters by mixing bleaching earth with oil under controlled conditions of temperature. After Shandong Leader Machinery Co.,ltd. proper mixing with bleaching earth for a specific residence time, the mixture is finally pumped into leaf filters with stainless steel mesh elements followed by polishing filtration.Deodorizing is the final stage in oil refining in order to remove odoriferous material, free fatty acids and other undesired minor components 1-20TPD Small Scale Oil Refining Line by steam distillation under condition of high temperature and vacuum to produce a bland oil with a good shelf life.

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

Email:[email protected]

Whatsapp:+86 13064099546

Skype:leaderfoodmachine21

Contact:Mandy

NOTE:We can specially design the machine according to your production's features.