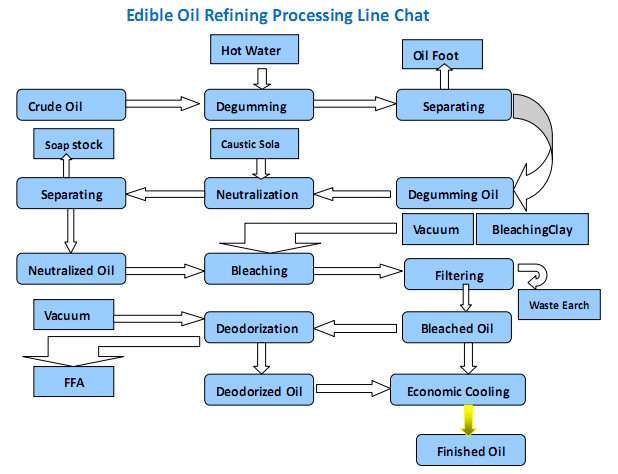

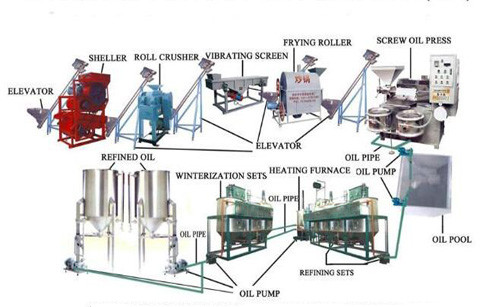

The objective of 1-20TPD Small Scale Oil Refining Line refining is to remove objectionable co-constituents in oil with the least possible damage to glycerides and minimal loss of desirable constituents 1-20TPD Small Scale Oil Refining Line. Ways of refining depend on nature and quantity of impurities contained in crude oil, application of RBD oil.Shandong Leader Machinery Co.,ltd. Classical chemical refining is used through successive steps: it must be degumming, neutralizing, bleaching, deodorizing and sometimes winterizing (Mainly removing free fatty acid and other minor constituents).The set of equipment has obtained national patent (patent No. is ZL99 25288.7), A new generation of peanut /soybean/sesame oil extruder is our developed third generation product with more advanced and mature technology, and it won GoldMedal on 8th China Fair of Inventions and New Technologies and Silver Medal on 6th International Invention Exhibition. 1-20TPD Small Scale Oil Refining Line adopts intermittent refining craft, and has advantages of convenient transportation, small covering area, less operation staff and saving energy.

Product DescriptionA new generation of peanut /soybean/sesame oil extruder

Technical parameters

| Machine Model | Cold Capacity(kg) | TPD | Hot Capacity(kg) | Machine Weight(kg) | Dimension(mm) | Main Motor Power (KW) | Heating Tube |

| 6YL-80 | 50-80 | 2 | 70-100 | 630 | 1650x1150x1750 | 6-5.5 | 2+1 |

| 6YL-100 | 100-140 | 3.6 | 120-180 | 870 | 1950x1300x1900 | 6-7.5 | 2+1 |

| 6YL-120 | 130-220 | 5 | 160-260 | 1280 | 2200x1650x2100 | 6-11 | 3.3+1.2 |

| 6YL-130 | 200-300 | 7 | 240-350 | 1420 | 2250x1650x2150 | 6-15 | 3.3+1.2 |

| 6YL-160 | 300-380 | 9 | 350-460 | 1600 | 2500x1600x2500 | 6-18.5 | 4+1.5 |

| 6YL-180 | 360-520 | 12 | 450-550 | 1800 | 2750x1750x2350 | 6-22 | 4+1.5 |

Prodict feature:

1.Squeezer using steel material seiko production,Reliable quality

Motor using national manufacturerscopper core motor, transmission gears thermal forgedpartspressed steelscrew using cr12abrasive material, to all customers a guaranteed minimum yield of 40kilograms, superior design, quality assurance.

2. press multistage press,the oil is high

Press multi-level press, increasing the pressure point, multi-level to promote and strengthen the

degree of crushing of raw materials, increase oil yield, accelerate productivity.

3.The press electronic temperature control,easy to operate

Press equipped with an electronic temperature control system, infrared synchronization heating, for different oil crops, different heating can be automatically improved press speed and fuel oil yield.

4.press virgin bore transformation designed

Traditional virgin boregroove design is unreasonable, resulting in incomplete oil outflow, many have been wasted. I plant press to squeeze bore reinventedunique groove design, easier oil outflow from the hardware to further improve theoil yield. Press usingcentrifugal filtration system device, to achieve a true sense of pressing the filter body, improve the automation of press, completely solve the problem of oil purification.

5. Oil mill universal press, multi-usage . Press can be pressed peanut, rapeseed, sesame, soybean, cottonseed, sunflower, flax, seed, tung nuts,seeds and chilipepper seeds, corn germ and other oil seeds, versatile multi-purpose, oil experts.

6.press production capacity,efficient operation

Press to adjust the feed system, made creative technological innovations on the screw, the feed significantly faster production volume increased significantly. A new generation of screw press with easy to use, high oil and other characteristics, which make the products have high purity, good quality and many other advantages. Not only improve the efficiency of machinery, but also save the production cost of the product, reducing the consumption of resources and labor, thereby increasing the profit value of the product

why choose us

1: Steel materials of the machine are purchased from the steel manufacturering factories directly, so the materials are in high quality

2: We have top engineer group and long-term cooperation with several research institutions,

3: Our workers are professional, each of them has been trained strictly before their job;

4: We supply the high grade, the consummation after-sale service.

Different types of machines and parts,We choose different material steel.

Oil mill has been working in high temperature,Demand has very good heat resistance.Our oil press are of good quality,Precision manufacturing, Oil mill has been working in high temperature,The high frequency quenching, heat treatment,High hardness, strength, good abrasion resistance,To adapt to the continuous operation of high temperature and high pressure, improve the service life of the oil press, use time can be up to several ten years.Reasonable spiral press chamber Using multistage advance gradual compression principle, make the pressing chamber pressure increases rapidly, isolating oil one-time fission, again USES the infrared temperature control system, automatic control of pressing temperature and moisture, to soften oil directly activate the oil molecules, squeezing the stable, a bleed, greatly improving the yield efficiency .

Packaging & Shipping

1. Have more than one overseas after-sales service center

2.Fault handing in 24 hours

3. Life-long technical service and maintenance

4 .Provide all kinds of accessories

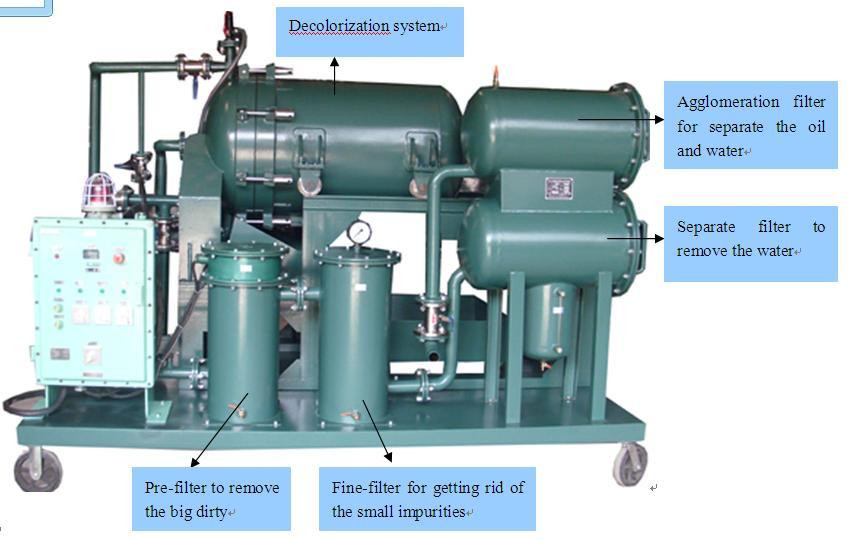

The purpose of 1-20TPD Small Scale Oil Refining Line degumming is to remove impurities such as phospholipids, gums and proteins etc. Shandong Leader Machinery Co.,ltd. are several methods as follows: water degumming, acid degumming, special degumming etc. Bleaching is the process operation which A new generation of peanut /soybean/sesame oil extruder removes colouring matters by mixing bleaching earth with oil under controlled conditions of temperature. After Shandong Leader Machinery Co.,ltd. proper mixing with bleaching earth for a specific residence time, the mixture is finally pumped into leaf filters with stainless steel mesh elements followed by polishing filtration.Deodorizing is the final stage in oil refining in order to remove odoriferous material, free fatty acids and other undesired minor components 1-20TPD Small Scale Oil Refining Line by steam distillation under condition of high temperature and vacuum to produce a bland oil with a good shelf life.

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

Email:[email protected]

Whatsapp:+86 13064099546

Skype:leaderfoodmachine21

Contact:Mandy

NOTE:We can specially design the machine according to your production's features.