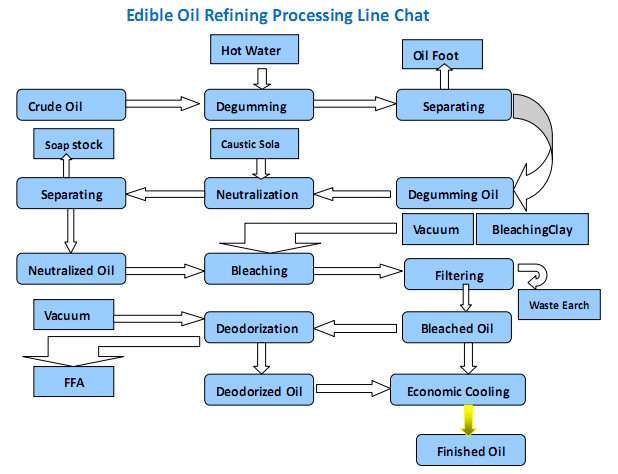

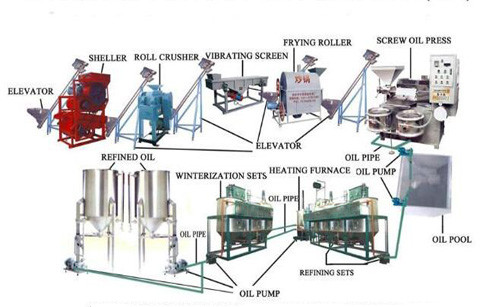

The objective of 1-20TPD Small Scale Oil Refining Line refining is to remove objectionable co-constituents in oil with the least possible damage to glycerides and minimal loss of desirable constituents 1-20TPD Small Scale Oil Refining Line. Ways of refining depend on nature and quantity of impurities contained in crude oil, application of RBD oil.Shandong Leader Machinery Co.,ltd. Classical chemical refining is used through successive steps: it must be degumming, neutralizing, bleaching, deodorizing and sometimes winterizing (Mainly removing free fatty acid and other minor constituents).The set of equipment has obtained national patent (patent No. is ZL99 25288.7), 2017 new type 5-10TPD Automatic wheat flour milling machine is our developed third generation product with more advanced and mature technology, and it won GoldMedal on 8th China Fair of Inventions and New Technologies and Silver Medal on 6th International Invention Exhibition. 1-20TPD Small Scale Oil Refining Line adopts intermittent refining craft, and has advantages of convenient transportation, small covering area, less operation staff and saving energy.

Automatic wheat mill machinery, wheat flour grinding mill, wheat powder grinding mill

NO. 1 Product Name and Code :

Automatic wheat mill machinery,wheat flour mill . This machine can be used in wheat,corn,millet,soybean,rice.

| Model | Capacity(kg/hr) | Power(kw) | Weight(kg) | Dimension(mm) | Packing size(mm) |

| LD-35 | 150-200 | 7.7 | 900 | 2450x950x3300 | 2600x1000x3500 |

NO. 2 Product features:

Automatic wheat mill machinery,wheat flour mill

1. advanced equipment, high automation, easy to operate

2. The long working hours are not easy to damage, reduce maintenance

3. mill fast, low power consumption

4. Especially suitable for individuals, small mills

5. You can make bread flour production, pizza, pasta, biscuits, dumplings

NO.3 Product Process :

Automatic wheat mill machinery,wheat flour mill

Wheat Flour Mill Machinery for Small Business .

We design this small sized flour mill special for individual household milling at small villages or towns. Employed on Automatic wheat mill machinery,wheat flour mill e unit of single passage roller mill, it can grind all kinds of cereals into very fine powder with LD quality. Equipped with one or two pieces of drum sifter which is silk nylon cloth, it can grade/sift the supplies into different sizes(40-150mesh size).

The whole set consists of a storage bin, one unit of high pressure air blower, one set of single passage roller mill, one set of drum sifter, air locks, cyclones and motors. The storage bin is A/B part separated which supply a circulating milling for the roller mill. The exit of high pressure air blower allows the grains be lifted and transformed pneumatic which saves a lot of manual labour.

NO.4 Our Service:

Automatic wheat mill machinery,wheat flour mill

Pre sales service: professional team to guide the analysis of the market, estimating costs, benefits.

Sales service: 1 engineers with the goods to the buyer on-site installation, use and problem handling training. Guarantee quality and service.

2 free distribution of spare parts, a year free maintenance treatment.

After sale service: a purchase, responsible for life.

NO.5 Our packaging :

Automatic wheat mill machinery,wheat flour mill

| Step | Package | Purpose |

| 1.Simple Split | Split of extruded parts | Prevent extrusion,narrow space ,conducive to transport |

| 2.Spare parts special packaging | Parts multilayer special protective film packaging | prevention of the appearance and performance of shock damage during transportation |

| 3.Whole plastic packaging | Sealed plastic film packaging | Fixed parts, to prevent falling collision, waterproof |

| 4.External wooden box | Closely fixed with the board in line with the requirements of import and export | Protection machinery, convenient to transportation |

|

5. 4 cases (4 mill) installed in one 20 feet container

| ||

NO.6 customer visit:

Automatic wheat mill machinery,wheat flour mill

We have a solid strength, to ensure the quality, professional after-sales, won the trust of customers around the world.The following are some of our customers come to buy equipment to visit the experimental operation of photos :

Kenya, the purchase of equipment :

Mozambique customer buying machinery

In order to protect the privacy of customers, other customers pictures inconvenience display.

Company Information

Henan LD Grain and Oil Machinery Engineering Co., Ltd(hereinafter referred to as LD) is specialized in undertaking turnkey projects covering Edible Oil Equipmentmt, Flour Milling Equipment, Feed Equipment and other related machineries. LD is engaged in designing, manufacturing, supply and installation and commissioning of a complete range of machinery/plants on a turnkey basis. The company offers customized turnkey solutions to the clients right from the very begin planning to commissioning and maintainance.

We are dedicated to supplying safer, more reliable and more environmental-friendly grain and food processing equipment and engineering services that create value for the clients. And our vision is to grow into a globally respectable market leader in its field.

Because we are young, so we are more dedicated!

If you would like to know more about us, please log in to our home!

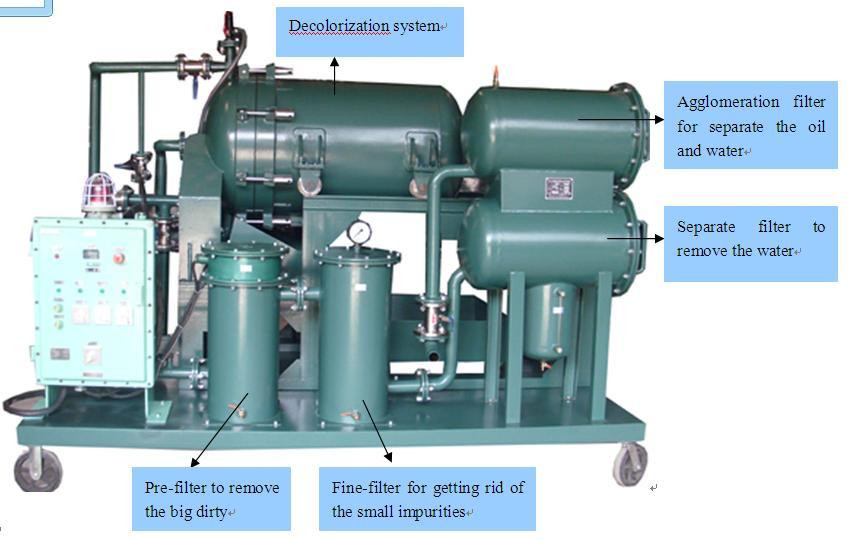

The purpose of 1-20TPD Small Scale Oil Refining Line degumming is to remove impurities such as phospholipids, gums and proteins etc. Shandong Leader Machinery Co.,ltd. are several methods as follows: water degumming, acid degumming, special degumming etc. Bleaching is the process operation which 2017 new type 5-10TPD Automatic wheat flour milling machine removes colouring matters by mixing bleaching earth with oil under controlled conditions of temperature. After Shandong Leader Machinery Co.,ltd. proper mixing with bleaching earth for a specific residence time, the mixture is finally pumped into leaf filters with stainless steel mesh elements followed by polishing filtration.Deodorizing is the final stage in oil refining in order to remove odoriferous material, free fatty acids and other undesired minor components 1-20TPD Small Scale Oil Refining Line by steam distillation under condition of high temperature and vacuum to produce a bland oil with a good shelf life.

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

Email:[email protected]

Whatsapp:+86 13064099546

Skype:leaderfoodmachine21

Contact:Mandy

NOTE:We can specially design the machine according to your production's features.