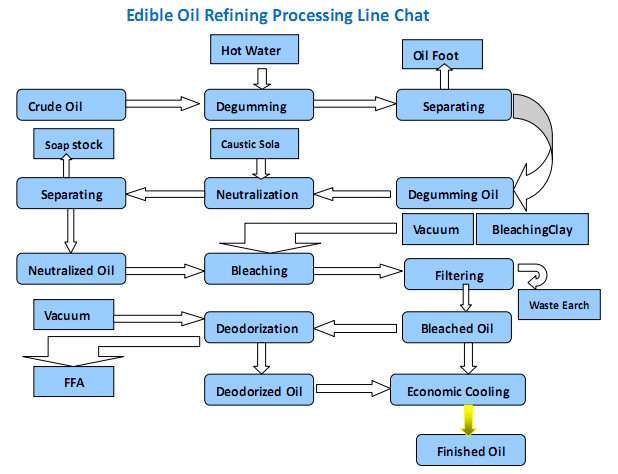

The objective of 1-20TPD Small Scale Oil Refining Line refining is to remove objectionable co-constituents in oil with the least possible damage to glycerides and minimal loss of desirable constituents 1-20TPD Small Scale Oil Refining Line. Ways of refining depend on nature and quantity of impurities contained in crude oil, application of RBD oil.Shandong Leader Machinery Co.,ltd. Classical chemical refining is used through successive steps: it must be degumming, neutralizing, bleaching, deodorizing and sometimes winterizing (Mainly removing free fatty acid and other minor constituents).The set of equipment has obtained national patent (patent No. is ZL99 25288.7), 6YL-120RL amphibious screw press machine for peanut oil is our developed third generation product with more advanced and mature technology, and it won GoldMedal on 8th China Fair of Inventions and New Technologies and Silver Medal on 6th International Invention Exhibition. 1-20TPD Small Scale Oil Refining Line adopts intermittent refining craft, and has advantages of convenient transportation, small covering area, less operation staff and saving energy.

6YL-120RL amphibious screw press machine for peanut oil

1. Features:

1) Both cold press and hot press available;

2) Higher oil yield, lower residue in oil cake;

3) Labor saving;

4) Energy saving

2. Specifications:

Model No. |

6YL-120RL |

Cold Press Capacity |

130-220Kg/Hr |

Hot Press Capacity |

160-260Kg/Hr |

Main Motor Power |

6-11Kw |

Heater Power |

3.3+1.2Kw |

Model No. For Vacuum Pump |

2X-15B |

Motor of Vacuum Pump |

4-2.2 |

Model No. For Filter Cask |

60 |

3. Pictures:

4. Operation principle:

When oil presses operating prepared materials enters extruding chamber from the hopper

and then moves forwards by the rotating pressing screw and that is pressed.

Under the high-pressure condition in the chamber,friction between material and screw, between

material and chamber,will be created, which also creates friction and relative movement among

material particles.On the other hand, root diameter of the pressing screw caries larger from one

end to the other.

When rotating, it not only pushes particles moving forwards but turns them outwards as well.

Meanwhile, particles adjacent the screw will rotate along with screws rotating, causing every

particle inside the chamber to possess different speed.

Therefore relative movement among particle creates heat which is necessary during manufacturing

because of helping protein change property, damage colloid, increase plasticity, decrease oils

elasticity resulting high oil productivity.

5. Company Introduction:

Henan LD Grain and Oil Machinery Engineering Co., Ltd(hereinafter referred to as LD)is specialized

in undertaking turnkey projects covering Edible Oil Equipment, Flour Milling Equipment, Feed Equipment

and other related machinery.

Our company has passed the international quality management system ISO 9001 and CE certificate.

LD has been undertaking more than 200 sets of oils and fats production turnkey projects, more than

300 sets of flour milling factories and more than 100 sets of feed mills in China and outside world.

6. Packaging:

7. Delivery:

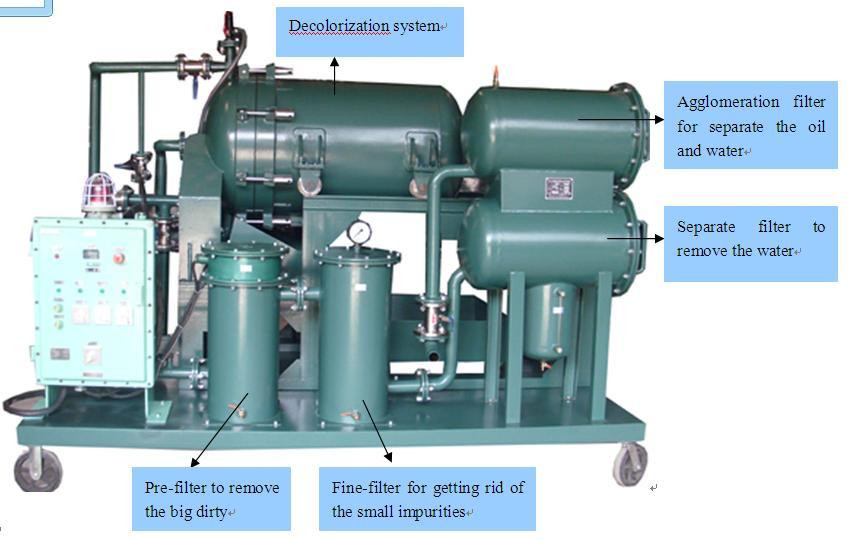

The purpose of 1-20TPD Small Scale Oil Refining Line degumming is to remove impurities such as phospholipids, gums and proteins etc. Shandong Leader Machinery Co.,ltd. are several methods as follows: water degumming, acid degumming, special degumming etc. Bleaching is the process operation which 6YL-120RL amphibious screw press machine for peanut oil removes colouring matters by mixing bleaching earth with oil under controlled conditions of temperature. After Shandong Leader Machinery Co.,ltd. proper mixing with bleaching earth for a specific residence time, the mixture is finally pumped into leaf filters with stainless steel mesh elements followed by polishing filtration.Deodorizing is the final stage in oil refining in order to remove odoriferous material, free fatty acids and other undesired minor components 1-20TPD Small Scale Oil Refining Line by steam distillation under condition of high temperature and vacuum to produce a bland oil with a good shelf life.

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

Email:[email protected]

Whatsapp:+86 13064099546

Skype:leaderfoodmachine21

Contact:Mandy

NOTE:We can specially design the machine according to your production's features.