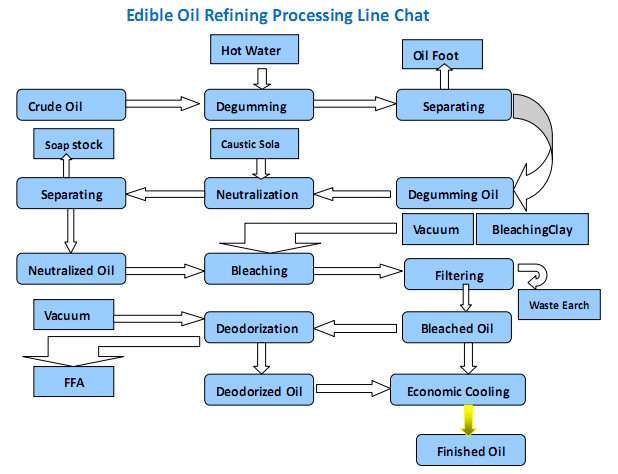

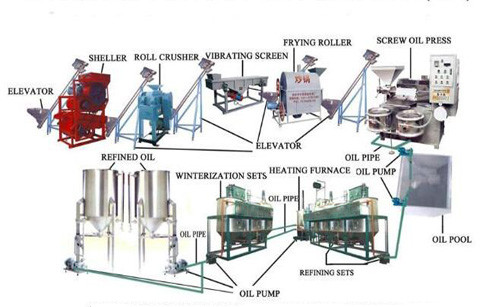

The objective of 1-20TPD Small Scale Oil Refining Line refining is to remove objectionable co-constituents in oil with the least possible damage to glycerides and minimal loss of desirable constituents 1-20TPD Small Scale Oil Refining Line. Ways of refining depend on nature and quantity of impurities contained in crude oil, application of RBD oil.Shandong Leader Machinery Co.,ltd. Classical chemical refining is used through successive steps: it must be degumming, neutralizing, bleaching, deodorizing and sometimes winterizing (Mainly removing free fatty acid and other minor constituents).The set of equipment has obtained national patent (patent No. is ZL99 25288.7), Distinctive Excellent 5 ton per day maize/wheat flour milling machine, wheat-flour-milling-machines-wi for sale with CE approved is our developed third generation product with more advanced and mature technology, and it won GoldMedal on 8th China Fair of Inventions and New Technologies and Silver Medal on 6th International Invention Exhibition. 1-20TPD Small Scale Oil Refining Line adopts intermittent refining craft, and has advantages of convenient transportation, small covering area, less operation staff and saving energy.

Features:

- The capacity is various from 60MT to 150MT wheat per day, flexible for customerâs choice.

- Compact design saves area and civil building costs less.

- Low investment and low power consumption which means running costs less.

- Elaborate machine combined with excellent design results in high quality flour and high yield

The processing chart of the wheat flour production line:

Complete set of grain flour grinding machinery can be divided into four parts: cleaning part, milling part, packing part and PLC controlling part.

1. Cleaning part

to clean out the middle and small impurity from wheat. e.g., dust, stone, magnetic material, wheat was bitten by insect and so on. Includes beating, screening, destoner, magnetic separator and dampening. This section is to prepare for milling part and to protect the machinery as well.

2. Milling part

The second step, to mill the grain and separate the flour, bran and other by-product:

(1) Mill: mill the grain to break the integrity by the roller moving

(2) Sifter: to separate the flour, bran and other by-product, also separate large size and small size to ensure flour quality.

3. Packing part

The third step, the packing machine can be manual or automatic weighting and packing.

4. PLC controlling system

To controlling the whole set of machinery to work well and showing the process of working.

Advantages:

1. Complete set of flour mill adopt various configuration modes for different purpose.

2. Help install the machine, ensure the machine operate efficiently. We also offer a varied of solutions on corn grits processing line.

3. The service life more than 20 years.

4. Perfect after-sales service and reasonable price.

Packing details: Standard wooden package or as customer's require

Delivery details: Within 15 days after we received down payment

Customers' Project Show

1 The South Africa customers 10Ton Wheat Flour Milling with Our engineers:

2Morocco Customers 1 TON Wheat Flour Single Machine Delivery

We guarantee:

--Machine heart parts are made in special strong Chrome-Mn alloy material. Keep working long hours.

--Every machine is tested with corn before shipping to customer with strict quality control system.

--One year quality guarantee period.

--24 hours online after sale service.

Customers' Visiting Pictures:

1Our Malawi customers came to visit us On November 15th,2015 for the order of the whole set of 1 Ton wheat production line.Our engineers show him a good solution for his project.He is satisfied with our service in the whole negotiation business.

2Our Peru customers told us the 3 sets of the wheat flour single machine has been arrived in his factory last week.It has been working on his project after our engineers helped him on the installation guide.He is so happy and will keep in touch in the following days.

Contact with us at any time if you also have needs on the wheat flour production or the other maize or corn flour production line now!

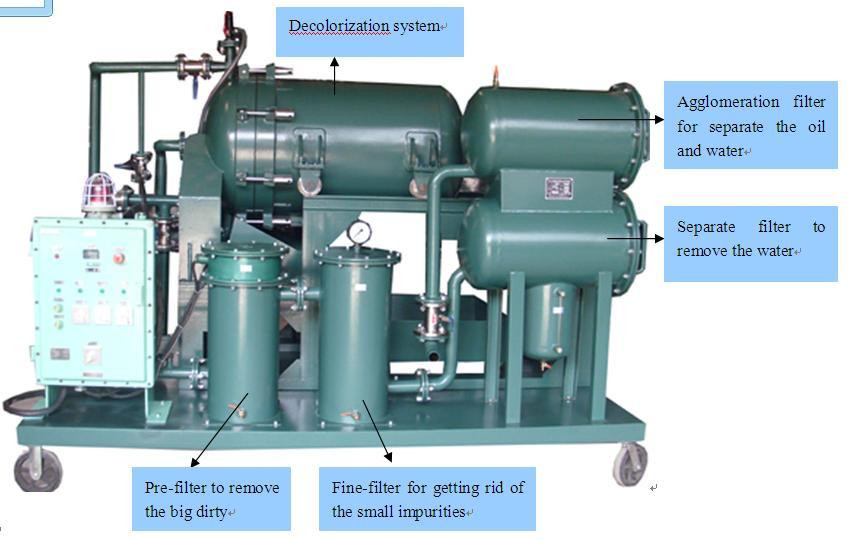

The purpose of 1-20TPD Small Scale Oil Refining Line degumming is to remove impurities such as phospholipids, gums and proteins etc. Shandong Leader Machinery Co.,ltd. are several methods as follows: water degumming, acid degumming, special degumming etc. Bleaching is the process operation which Distinctive Excellent 5 ton per day maize/wheat flour milling machine, wheat-flour-milling-machines-wi for sale with CE approved removes colouring matters by mixing bleaching earth with oil under controlled conditions of temperature. After Shandong Leader Machinery Co.,ltd. proper mixing with bleaching earth for a specific residence time, the mixture is finally pumped into leaf filters with stainless steel mesh elements followed by polishing filtration.Deodorizing is the final stage in oil refining in order to remove odoriferous material, free fatty acids and other undesired minor components 1-20TPD Small Scale Oil Refining Line by steam distillation under condition of high temperature and vacuum to produce a bland oil with a good shelf life.

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

Email:[email protected]

Whatsapp:+86 13064099546

Skype:leaderfoodmachine21

Contact:Mandy

NOTE:We can specially design the machine according to your production's features.