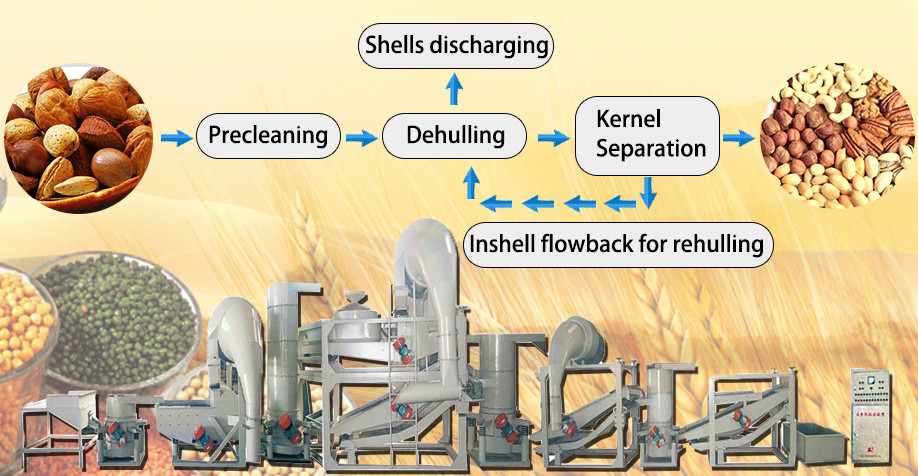

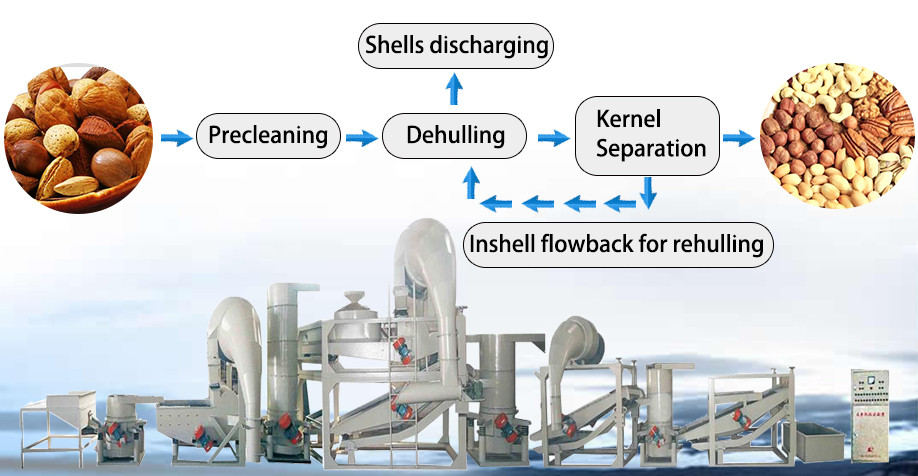

It features as following:

·it adopts wet method for dehulling process.

·make it more efficient on dehulling rate and lower broken rate through improvement on existing dehullers.

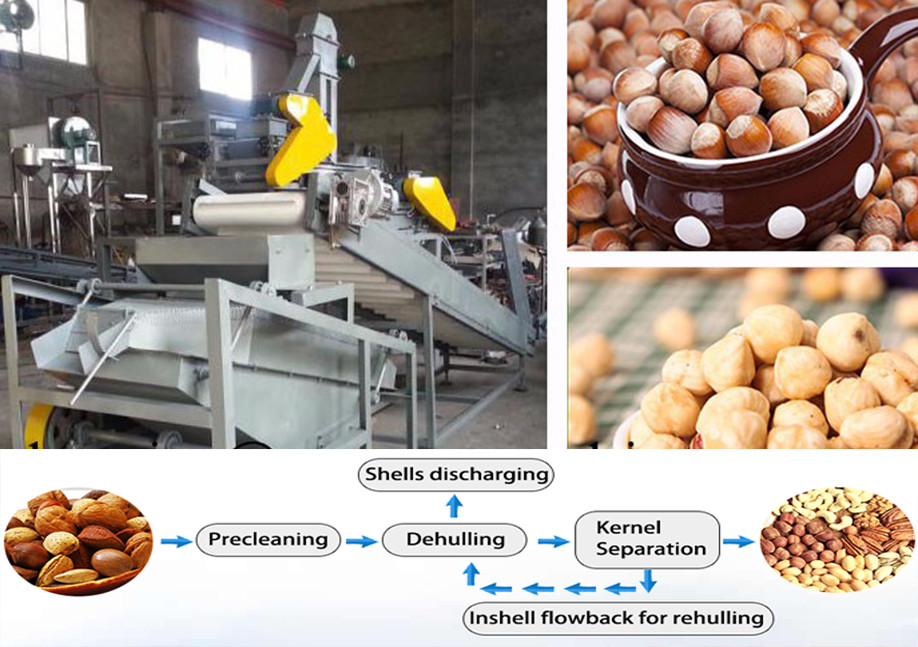

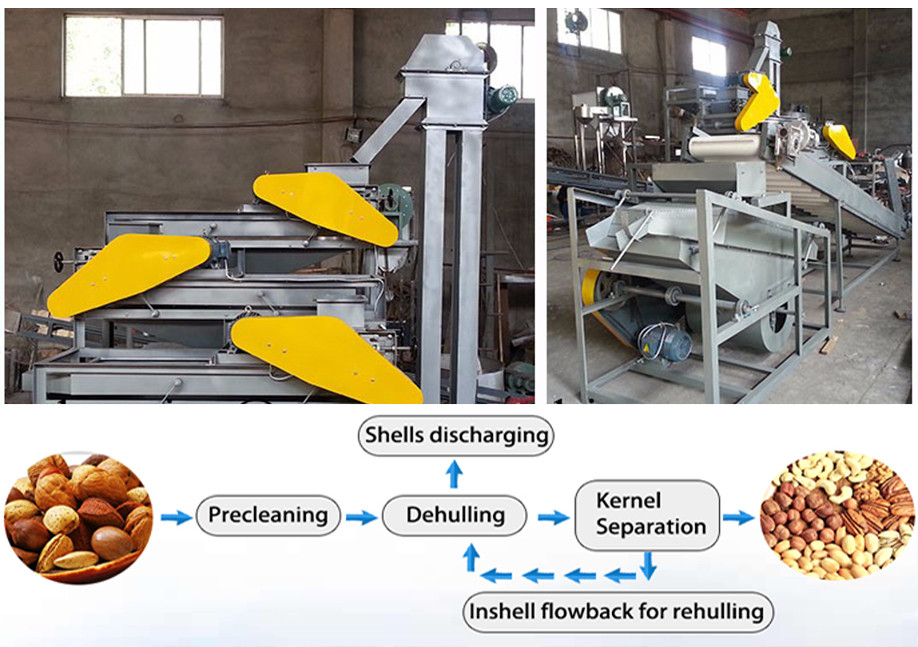

·it adopts recycled dehulling process, that is to say the unhulled seeds will go back for recycled dehulling automatically.

·It adopts negative-pressure method to suck the shells out instead of blowout to reduce the dust quantity.

·Increase the distance and area of the separation screening, make seed-kernel separation works more thoroughly,

thus reduce the persentage of broken due to more kernels going back to dehullers for redehulling.

·The screening section is changeable as per the individual size of the pumpkin seeds

·Compact design, low loss of materials and easy maintenance.

Improved-design of dehullers make the dehulling Screen mesh made from punching works of

process more efficient premium quality cold rolled sheet,durable service.

Prevent mesh from blockage due to the bouncing

ball design.

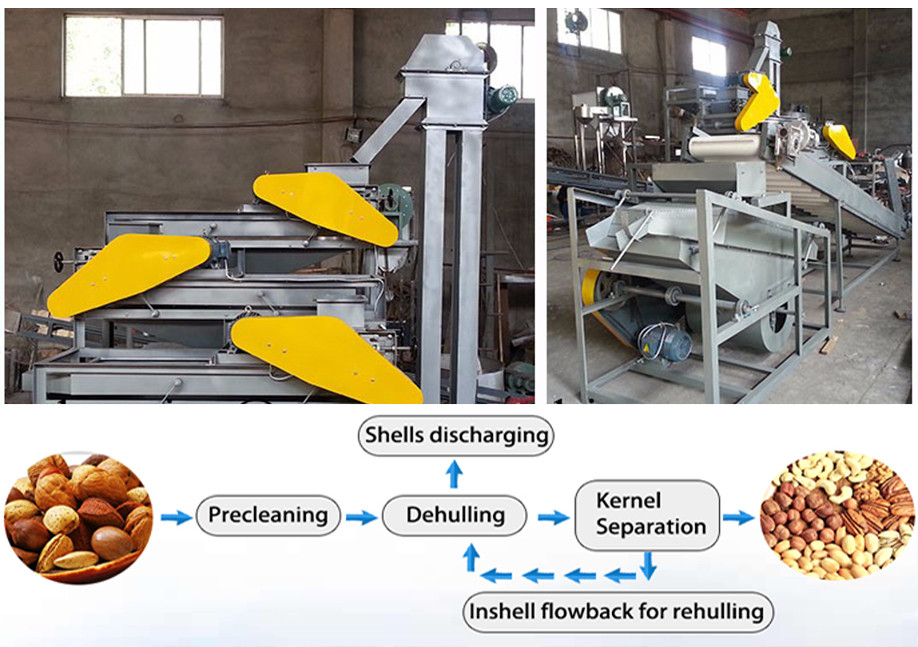

Wider&longer screening design Adopt the vibrating and negative- Vibration source of the

make the seed-kernel pressure separation works and spiral equipment adopts vibratory

separation works more discharging for shells-discharge to motors design, features easy

efficient. make the shells collecting works and quick installation, no

easier and meanwhile reduce the foundation works requires.

dust accumulation greatly during process.

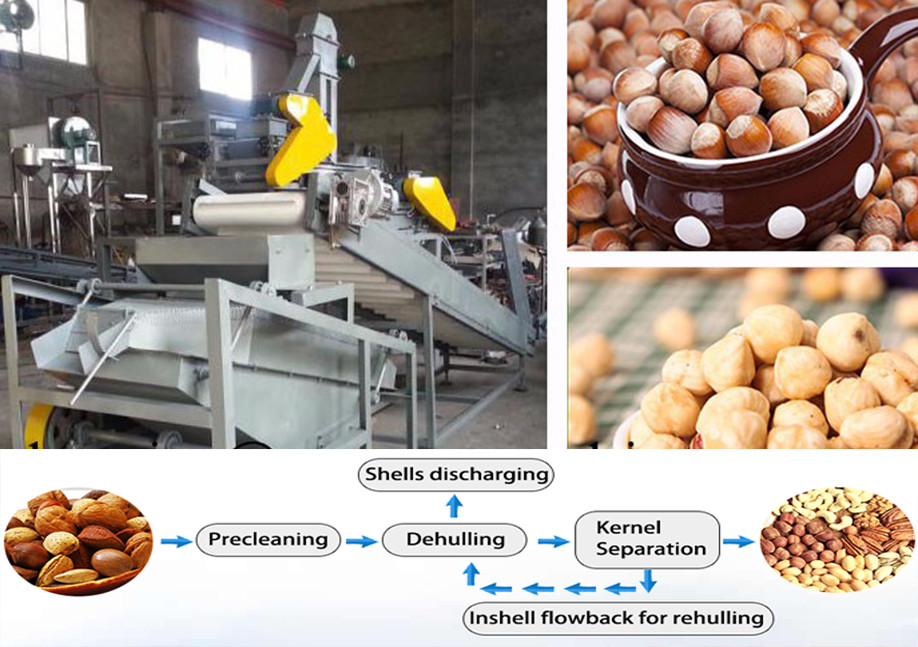

[Component]

It consists of input hopper (1), bucket elevator (2), dehullers (3), electric control cabinet (4).

[Process]

| [Technical parameters] |

| Power: 8.19kw(380v) % of whole kerenls:95% min. (kernels that are less than 1/2 whole kernels are brokens) % of inshell in final kernels: 2% maximum Input capacity: 200-300kgs/hour Space occupied: 6.5m×2.9m Height:3.5m Weight:2.5mt |

Meantime, we also specialize in cleaning, dehulling & separating machines and equipments for Sunflower seed, Buckwheat, tartary buckwheat, oat, job's tears, perilla seed, flaxseed (linseed), mung bean (green bean), safflower seeds, Silybum seed, almond, hazelnut, Gordon Euryale Seed, Jatropha seed, acorn, peach inshell, etc. in China.

Salable Pumpkin seed desheller, deshelling machine BGZ300 from Shandong Microwave Machinery Co.,Ltd.

Salable Pumpkin seed desheller, deshelling machine BGZ300 is also known as dental sheller which Salable Pumpkin seed desheller, deshelling machine BGZ300 is widely used, seed dehulling machine is commenly used for cotton

seeds, but seed dehulling machine also can be used for other oil crops such as sunflower, peanuts, fruit, tung oil, etc.

Salable Pumpkin seed desheller, deshelling machine BGZ300, can be used to break various kinds of oil crops and the cake has been broken.

Salable Pumpkin seed desheller, deshelling machine BGZ300 using its rough surface rubbing crushed to make crops shell broken. Salable Pumpkin seed desheller, deshelling machine BGZ300 characteristics are the simple structure and easy to adjust.Salable Pumpkin seed desheller, deshelling machine BGZ300 is characterized by disc Sheller with large capacity, high rate of broken shells,

low power consumption, easy adjustment.

Features of Salable Pumpkin seed desheller, deshelling machine BGZ300

1.Cheap price, corrosion resistant of Salable Pumpkin seed desheller, deshelling machine BGZ300

2.Good quality of Salable Pumpkin seed desheller, deshelling machine BGZ300,

3.Salable Pumpkin seed desheller, deshelling machine BGZ300 is easy handle

1.Salable Pumpkin seed desheller, deshelling machine BGZ300 can thresher the sunflower seeds automatically

2.Salable Pumpkin seed desheller, deshelling machine BGZ300 can put 4-5 sunflower one time

1. Brief introduction of Salable Pumpkin seed desheller, deshelling machine BGZ300

seed dehulling machine can thresher the sunflower seeds automatically ,then you can put the oil press machine to press sunflower oil .

Motor of seed dehulling machine : 2.2kw

Capacity of Salable Pumpkin seed desheller, deshelling machine BGZ300 : 3000-4500 pcs/h

Dimension of Salable Pumpkin seed desheller, deshelling machine BGZ300 : 850*800*1200mm

Salable Pumpkin seed desheller, deshelling machine BGZ300 from Shandong Microwave Machinery Co.,Ltd.

Shandong Microwave Machinery Co.,Ltd.is a seed dehulling machine factory specializing in the production of Salable Pumpkin seed desheller, deshelling machine BGZ300, scientific research,manufacturing,installation, commissioning.Shandong Microwave Machinery Co.,Ltd.can provide seed dehulling machinecustomers with design and services of 1-2000 tons Salable Pumpkin seed desheller, deshelling machine BGZ300. Shandong Microwave Machinery Co.,Ltd. have finished hundreds of successful projects seed dehulling machineover the years: peanut oil, soybean oil, rapeseed oil, cottonseed oil, sunflower oil, sesame oil, animal oil,grape seed oil, acer truncatum oil, peony seed oil, walnut oil, hemp seed oil, pine oil, tea seed oil, papaya oil, milk thistle seed, and other special type seed dehulling machineoil. Shandong Microwave Machinery Co.,Ltd. have independent import and export department. Shandong Microwave Machinery Co.,Ltd. seed dehulling machineequipment has been successfully exported to more than ten countries: Russia, Australia, India, Afghanistan, Cameroon,and so on.

Contact us:

Carrie-Sales manager

Shandong Microwave Machinery Co.,Ltd.

Web: www.epier.com

Email: [email protected]

Skype:leaderfoodmachine10

Moblie:0086-15020017267(also WhatsApp)