best performance good quality Industrial Microwave oven produced and supplied by Shandong Microwave Machinery Co.,Ltd.

Contact us:

Carrie-Sales manager

Shandong Microwave Machinery Co.,Ltd.

Web: www.epier.com

Email: [email protected]

Skype:leaderfoodmachine10

Moblie:0086-15020017267(also WhatsApp)

Microwave Drying And Sterilizing Equipment for Wood Products is used to dry or sterilize powders, granular, sheet-like or gel-like food, and additive, spices, flavoring, medicine, raw material of best performance good quality Industrial Microwave oven , nutritional health products, agricultural & sideline products, non-fired(or oil saving)instant noodles, noodles, rice powder needles, soy products, beef jerky, preserved meat, dried fish, tea, tobacco and so on.

Features of Microwave Drying And Sterilizing Equipment for Wood Products:

According to different best performance good quality Industrial Microwave oven customers’ requirement, Shandong Microwave Machinery Co.,Ltd. supply different types best performance good quality Industrial Microwave oven for your choice.

Microwave Drying And Sterilizing Equipment is multifunctional. It can dry, sterilize and heat.

PLC computer control system of best performance good quality Industrial Microwave oven control the humidity, temperature, and time of drying high accurately, easy

to operate.

best performance good quality Industrial Microwave oven has features of nice seal, high efficiency, fully automatic, low energy consumption and so on.

The belt of best performance good quality Industrial Microwave ovenis with clean materials which can match different foods requirement.

The belt speed of Microwave Drying And Sterilizing Equipment can be controlled by inverter.

The series of best performance good quality Industrial Microwave oven is widely used in industry, agriculture, chemical, medicine, wood and so on.

Product Description

Introduction of Industrial Microwave Oven :

Microwave refers to the electromagnetic waves frequency between 300MHz-300GHz, wavelength is between 1mm to 1m. Microwave usually shows penetration, reflection and absorption characteristics. For glass, plastic and porcelain, microwave will penetrate it without being absorbed. For water and food, it will absorb microwave and heating itself. For metal material, it will reflect the microwave. Water molecule is polar molecule, it will change its polarity and friction motion cause by the effect of high speed change of high frequency electromagnetic field. Then the microwave electromagnetic field energy can be converted into heat energy, and achieve the purpose of drying. Microwave uniform heat up the material inside and outside because of the strong penetrability, will not appear outside dry but inside wet. Body heat source state formation shortens the time of heat conduction and save a lot of drying time. Microwave sterilization temperature is from 70°C to 105°C, period is from 90 to 180 seconds. Microwave thermal effects change the bacterial protein, make it lose nutrition, reproduction and survival conditions and death. Microwave electromagnetic field can make normal growth and stability of the genetic breeding of bacteria nucleic acid [RNA] and deoxyribonucleic acid [DNA] number of hydrogen bonds slack, breakage and recombination, thereby inducing genetic mutations, chromosomal aberrations and even rupture.

Microwave Drying Advantages:1) Industrial Microwave Oven effect at once, power adjustable, transmission speed adjustable, no thermal inertia residues, compare with the conventional process equipment to save energy by 50%.

2) Industrial Microwave Oven make the material itself become body heat source state, no need heat transfer process, can achieve the drying temperature within a very short time.

3) Due to the fast drying speed, microwave drying machine maximally save the activity of the materials, nutrition ingredient and the original color.

4) Industrial Microwave Oven uniform heat up the material inside and outside because of the strong penetrability, will not appear outside dry but inside wet.

5) Industrial Microwave Oven can fast sterilization under low temperature sterilization, material store for a long time will not mildew.

6) Microwave leakage control in metal drying chamber and the waveguide, no radiation damage and harmful gas emissions, not produce waste heat and dust pollution, microwave drying is efficient and economic environmental drying mode.

Specification of food extruder:

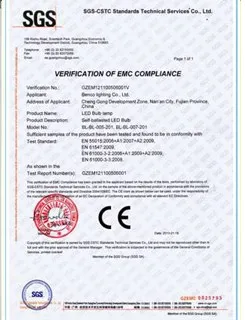

Certifications

Certifications

Detailed Images

Detailed ImagesFeatures of machine parts:

Our Service

Our Service

Pre-Sales Service:

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service:

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Contact To Us:

Mr. (Director of sales department)

Skype:

Mob(whatsapp):+0086

Tel:+0086 531 85927300

Shandong Microwave Machinery Co.,Ltd.is a Microwave Drying And Sterilizing Equipment factory specializing in the production of best performance good quality Industrial Microwave oven, scientific research,manufacturing,installation, commissioning.Shandong Microwave Machinery Co.,Ltd.can provide Microwave Drying And Sterilizing Equipmentcustomers with design and services of 1-2000 tons best performance good quality Industrial Microwave oven. Shandong Microwave Machinery Co.,Ltd. have finished hundreds of successful projects Microwave Drying And Sterilizing Equipmentover the years: peanut oil, soybean oil, rapeseed oil, cottonseed oil, sunflower oil, sesame oil, animal oil,grape seed oil, acer truncatum oil, peony seed oil, walnut oil, hemp seed oil, pine oil, tea seed oil, papaya oil, milk thistle seed, and other special type Microwave Drying And Sterilizing Equipmentoil. Shandong Microwave Machinery Co.,Ltd. have independent import and export department. Shandong Microwave Machinery Co.,Ltd. Microwave Drying And Sterilizing Equipmentequipment has been successfully exported to more than ten countries: Russia, Australia, India, Afghanistan, Cameroon,and so on.