Shandong Leader Machinery Co.,ltd. was founded in 1997,whcih is a large-scale oil machinery manufacturing Oilseeds pretreatment plant Equipment enterprise integrating R & D, design, manufacture and installation as one of the major grain and oil machinery manufacturing enterprises in China.Our company headquartered located in ShanDong Province,China,covering 100,000.00 square meters. Oilseeds pretreatment plant Equipment is committed to develop into a modern international oil machinery goal.Our company was named the outstanding member of the Chinese Cereals and Oils Association, the provincial contract and trustworthy enterprises, the provincial enterprise technology center.Huatai machinery has the rights of import and export, passed ISO9001: 2008 quality system certification.Now,the company is adhering to the scientific management of modern enterprises Good preferance automatic Sunflower/soybean/palm kernel oil pressing machine, precision manufacturing, innovation, and the rapid rise of a domestic grain and oil machinery manufacturing leader deserved.

Product Description

Product description of palm kernel oil pressing machine:

6YY-230 new hydraulic press, is the introduction of similar products on the basis of foreign to be improved design. Easy to use, easy to operate, the oil rate is high.

The machine is the stir-fried oil directly into the barrel to squeeze out the oil, with a simple and quick process, direct outflow of pure tendency to participate in there, the user witnessed the next few minutes can be processed oil, so that customers eat Relaxed oil.

Main Features of palm kernel oil pressing machine:

1) Engineer guide you installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) Regard quality as the company life ,regard user as the god,mutual benefit and win-win situation with integrity,tenet.

4) Running in a high automatization and intellectualization,no pollution.

5) Long life to use, and 24 hours online service for you.

Main parts and characteristics of palm kernel oil pressing machine:

Cylinder is made of hydraulic cylinder, piston, cylinder gland, hexagon screw, oil seal (made of imported polyurethane material, high pressure, high temperature, wearable, long-term use), hydraulic two-way cylinder is characterized by oil pump Oil to the cylinder inside the piston forced rapid rise, rapid decline, short time, high efficiency, high degree of automation, no need to worry about falling cylinders and other issues, do not want similar products at home and abroad from the oil cylinder in a short time too thick hydraulic oil, In the winter is more serious, oil seal aging, resulting in a long time not fall from the oil tank, the need for artificial hammer, bar down pressure to slow down, within a year need to replace several hydraulic oil, so laborious, laborious, time-consuming, and even The machine can not be used normally and affect the benefits. Therefore, the company developed the hydraulic two-way cylinder in the use of thick operation is simple, fast, save time, high efficiency.

Electrical control is composed of voltage meter, micro temperature controller, electrical contact pressure gauge, contactor, relay, infrared heating tube, click and other components.

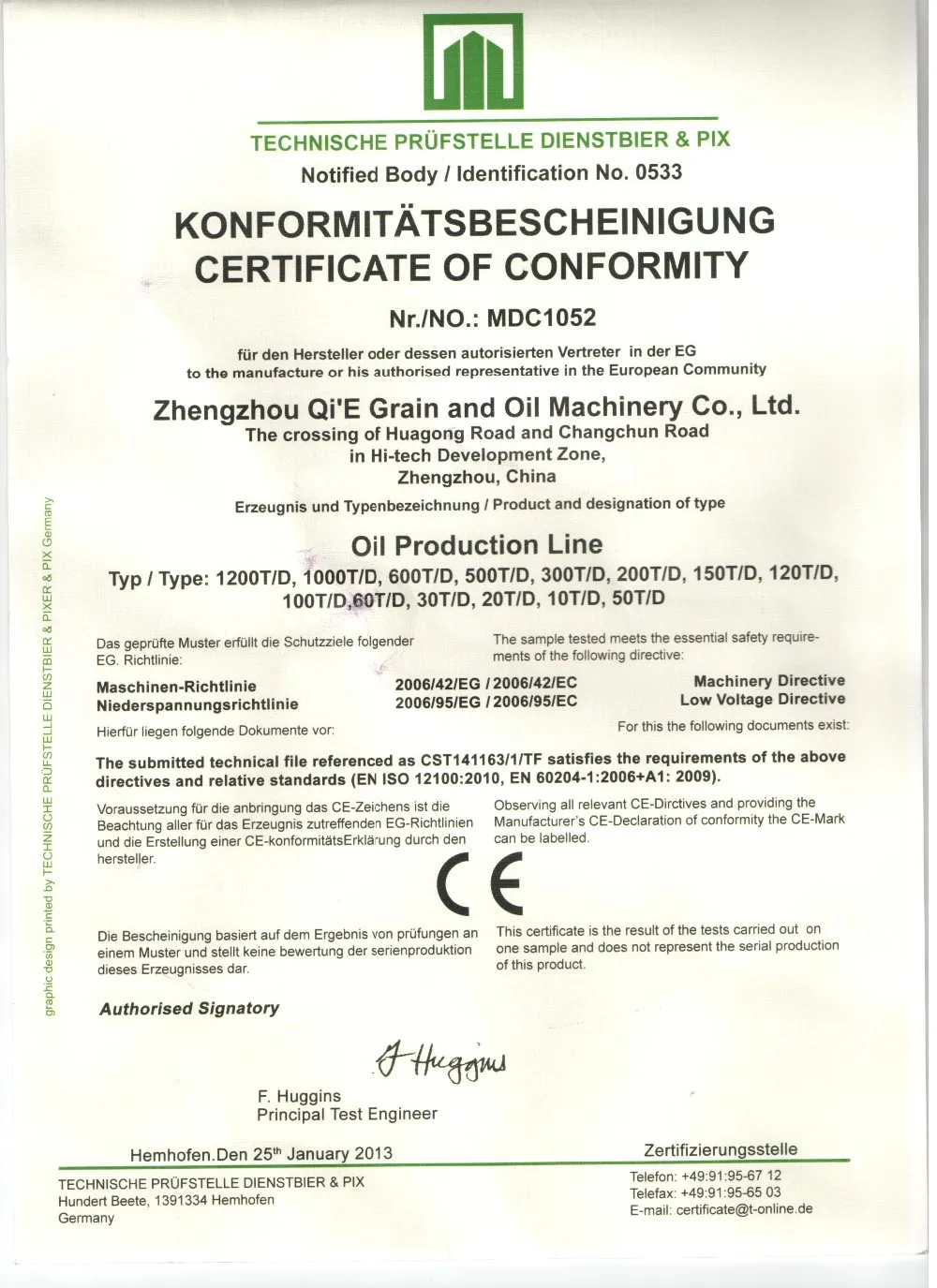

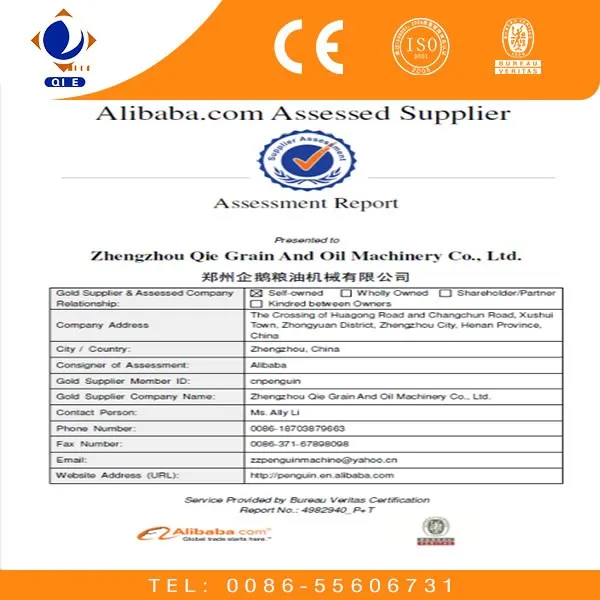

Certifications

Certifications

Detailed Images

Detailed Images

Machine Parts

Name: Pretreatment Plant

Brand: LD

Original: China

Rice bran extrusion flow chart:

Rice branâMagnetic separationâCleaning âExtrusion Puffing âCounter-current dryingâTo leaching plant

Main Features

Name: Cleaning process

Brand: LD

Original: China

Adopt the magnetic separation removing iron miscellaneous and vibration sieve removing broken clear, rice Xi, etc.

Machine Parts

Name: Extrusion process:

Brand: LD

Original: China

Adopting the bulking machine can both improve the yield of rice bran oil and reduce the consumption. The extrusion puffing, on the one hand, can make solution lipase in the rice bran passivated under high temperature and high pressure condition,then prevent the rice bran oil rancidity; On the other hand, the extrusion puffing can make rice bran be porous mateial grain, and increases the materials bulk density, then improve the permeability and leaching rate which solvent reacts to the material.

Main Features

Name: Drying process

Brand: LD

Original: China

The puffed rice bran contains about 12% water, and the best moisture for leaching process is 7-9%, therefore, there must be effective drying means to achieve the best leaching moisture.Adopting counter-current dryer can make water and temperature meet with follow-up process requirements, and improve the oil yield, as well as oil quality.

FAQ

FAQ

Company Profiles:

Shandong LD Grain&Oil Machinery Co.,Ltd is a large-sized joint-equity enterprise which specialize in producing edible oil mechanical equipment and it is also a group enterprise integrating scientific research, manufacturing, sales as one. Research Institute of Machine Design Company and Henan, Henan University of Technology (formerly the Shandong Grain College) school-enterprise cooperation in the oil equipment to carry out long-term, protein extraction, phospholipid extraction, etc. R & D and application of new technologies.

Main business:

10-500T/H oil material first cleaning,drying and storage section turn-key project.

100-3000 T/D oil pretreatment, shelling and pre-press workshop turnkey project (soybean hot peeling, bean skin crushing; the soybean extrusion, high oil contained pre-press cake extrusion, and high oil contained embryos puffed; of direct puffed). Rice bran production line turn-key project.

Leaching workshop turnkey project (Towline extractor, Rotocel extractor, loop type extractor, DTDC separated machine, the full negative pressure evaporation, paraffin wax recovery, leaching workshop degum, phospholipid concentrate).

30-1000T/D oil continuous grade two or one physical (chemical) refining production line.

20-600T/D sunflower oil, rice bran oil, corn germ oil dewaxing turn-key project.

10-200T/D Fatty acid esterification production cooking oil production line, and so on.

Our Service

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

| Packaging | |

| Size | 123 (L) * 456 (W) * 789 (D) |

| Weight | 1.2 T |

| Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

| Packaging | |

| Size | 123 (L) * 456 (W) * 789 (D) |

| Weight | 1.2 T |

| Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

Please send the inquiry to me, waiting for your coming to China and visit our plant.

In order to obtain high effective cleaning, ensure good work condition and production stability, high efficient vibration screen Good preferance automatic Sunflower/soybean/palm kernel oil pressing machine was used in the process to separate big and small impurity. Suction type gravity stoner removing machine Oilseeds pretreatment plant Equipment was applied to remove the shoulder stone and earth, and magnetic separation equipment without power and exhaust system were used to remove iron. Dust removing wind net is installed. soybean oil machine Good preferance automatic Sunflower/soybean/palm kernel oil pressing machine.soybean oil extraction machinery's Good preferance automatic Sunflower/soybean/palm kernel oil pressing machine oil extraction is continuous screw press machine Oilseeds pretreatment plant Equipment which is suitable to the plant oil materials which has high oil content. oil extraction plant.The instruction of the cake is loose and easy to make the solvent permeate ,Shandong Leader Machinery Co.,ltd. the oil content of cake and moisture used for solvent extraction.

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

Email:[email protected]

Whatsapp:+86 13064099546

Skype:leaderfoodmachine21

Contact:Mandy

NOTE:We can specially design the machine according to your production's features.