According to the difference of alkali thickness and oil temperature for 1-20TPD Small Scale Oil Refining Line, the process of dealkalizing of Full automatic peanut oil making machine is divided into two types, one is low temperature with thick alkali (its initial temperature is 20 ~ 30 ℃, alkali thickness is 20 ~ 30 Be) and another one is high temperature with light alkali (its initial temperature is 75 ℃, alkali thickness is 10 to 16 Be). The former of Full automatic peanut oil making machine is generally applied and the latter of Full automatic peanut oil making machine is mainly used for crude oil which has low acid value, light clour and lustre, and less impurity.

Specifications of 1-20TPD Small Scale Oil Refining Line:

1. soy lecithin

2. suite for soybean, corn germ, peanut, sesame, rapeseed, rice bran, cottonseed, tea seed, sunflower seed oil press

3. pure oil, edible oil quality

4. various capacity:10t/d, 20t/d, 30t/d, 40t/d, 50t/d, 60t/d, 70t/d, 80t/d,100t/d, 150t/d

5. used for hot and cold press

Product Description of 1-20TPD Small Scale Oil Refining Line:

1. What is the Full automatic peanut oil making machine?

Raw material→Materials dosing →Magnetic separation→Cleaning→crusher→flaker→ Extrusion Puffing →Counter-current drying→To leaching plant

2. What is 1-20TPD Small Scale Oil Refining Line?

Material embryos→Extraction→Wet meal→Evaporation→Cooling→Product meal packing

↓

Mixed oil→Filter→Negative pressure evaporation → Crude oil→Solvent recovery

Shipping of Full automatic peanut oil making machine:

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door,

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving,

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms of Full automatic peanut oil making machine:

1. Payment: T/T, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery,

2. MOQ: 1pcs,

3. Warranty : 3 year

Full automatic peanut oil making machine

Company InformationJinan Best Grain & Oil Machinery Engineering Co., Ltd. which specialize in producing edible oil mechanical equipment, a group enterprise integrating scientific research, manufacturing, sales as one . BEST has been undertaking more than 200 sets of oils and fats production turnkey projects . Our company has passed the international quality management system ISO 9001 and CE certificate. It has the qualification of manufacturing one or more types of pressure vessel .

Go with BEST, to be the best. Do what you think-BEST!

Product Description

Full automatic peanut oil making machine

Best offer 5-1000tons of various oil pretreatment, leaching, squeezing engineering for you , Experienced technical personnel to provide first-class technology and mechanical design , From design (process, civil, electrical), manufacturing, installation, commissioning and after-sale full service, Advanced automation control system to ensure the whole production line of automatic and smooth running .

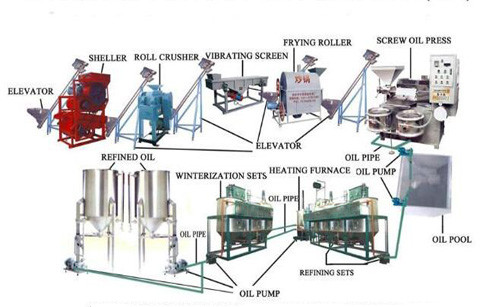

Pretreatment process feature

1.different combinations of process can process various oil plants in one workshop

2.Use special intensified pretreatment technology for aroma peanut oil to make it more aroma

3.Adopt advanced and reliable shelling technology to meet higher requirements for protein content meal

4.Extrusion treatment is use for raw materials with hard extraction,large-sized powder,and large capacity,which can reduce residual oil and solvent consumption,and increase the capacity by 50-80%

5.The new technology of shelling and low-temperature treatment can ensure high protein and least denaturation.

The establishment of oil pretreatment process , a variety of factors is oil varieties, take oil technology, product quality indicators, comprehensive utilization of oil , investment scale, So there are a number of alternative .Press process is relatively simple and can be based on the overall oil production process and product quality requirements, select press, pre-press, hot press, cold-pressed .

our advantages

(1) Professional technical team, provide strong support for the equipment manufacturing and installation.

(2) Equipment of the steel we choose SS/CS, has many years experience and very professional workers engaged in welding and assembly. Don't worry about the quality of the product.

(3) We have our own factory, there is no third party sales, so our price is lower.

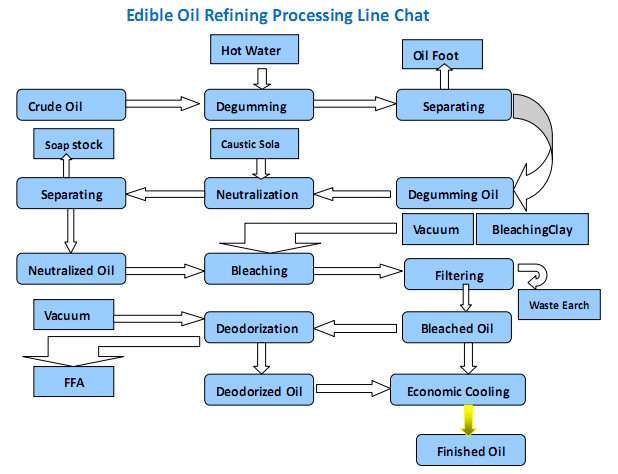

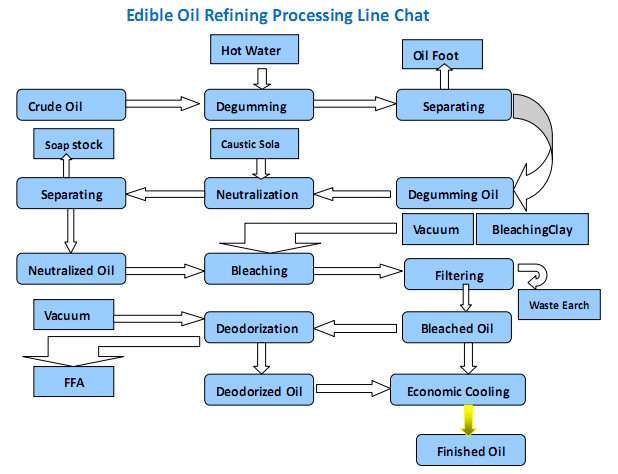

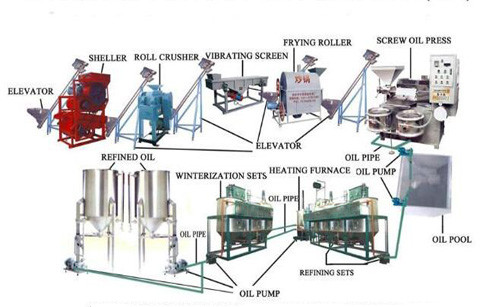

Refining process

Degumming and deacidification: The gumming is moved by phosphoric acid and hot water. There are two ways to move the acid in the edible oil. One is chemical way, the other one is physical way.The chemical way is using NaOH to react with acid. This way is suitable for the capacity of 5-30T per day. The physical way is using steam and centrifugal to move the acid. This way is used for capacity from 30-2000T per day.

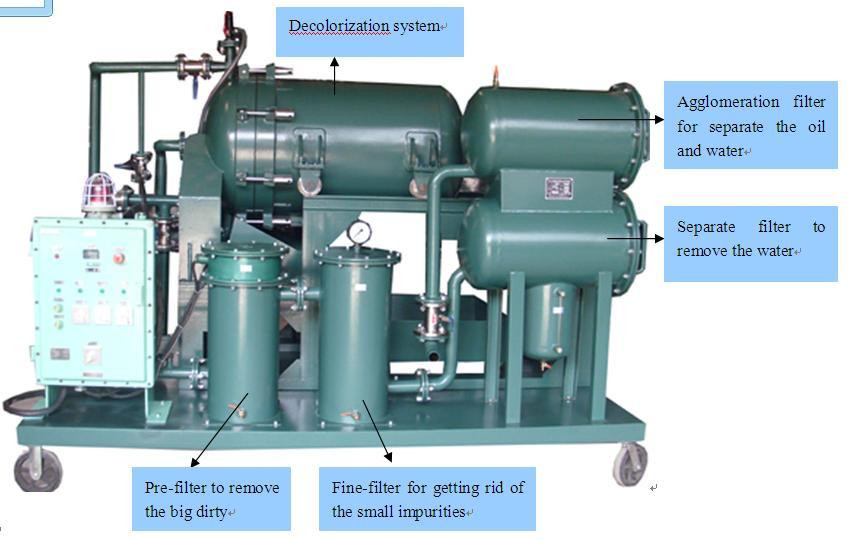

Decolorization: This step is used to adjust the color of the oil. You can control the color of the edible oil according to the requirement of your market.

Deodorization: The function of this step is to move the special smell in the oil. This is an important standard for refined edible oil.

Main business field

---10-500T/H oil material first cleaning,drying and storage section turn-key project.

---100-3000T/D oil pretreatment,shelling and pre-press wokshop trunkey project:rice bran production line turn-key project.

---100-300T/D leaching workshop trunkey project.

---30-1000T/D oil continuous grade oen or two physical(chemical)refining production line.

---20-3000T/D sunflower oil,corn germ oil dewaxing turn-key project.

---10-200T/D Fatty acid esterification production cooking oil production line.

Packaging & Shipping

Our Services

--- Ensure to timely provide complete sets of equipment and accessories.

---Ensure that one-time installation debugging acceptance.

--- To provide high quality material with preferential price.

---Free training technological operator to ensure the trained staff can operation independently

--we will offer an experienced project manager, organize a good installation team for the work of field installation debugging.

Warranty period: 2 years from the date you bought our machine.

The following situations are not included in our warranty.

(1) The damage which you did not according to our service manual.

(2) Normal spoilage of the quick-wear part.

(3) Someone who canât use and maintain the oil press machine.

Whether the oil press machine is in our maintenance range or not, our after-sale service team all can help you to repair

Shandong Leader Machinery Co.,Ltd. value "honesty, innovative and quality" because Shandong Leader Machinery Co.,Ltd. know that Shandong Leader Machinery Co.,Ltd. are not only supplying equipment to our clients but the partners to help our clients to get a better result.Keeping this in our mind,Shandong Leader Machinery Co.,Ltd. not only make high quality food processing equipment, but also help the clients to figure out the optimum processing work flows,make amendments according to client's specific needs,training staffs for the user of our equipment and even more, because Shandong Leader Machinery Co.,Ltd. believe that our users or clients' success is the foundation of ours.

Shandong Leader Machinery Co.,Ltd. is one of the leading Manufacturers and Suppliers of Full automatic peanut oil making machine.Shandong Leader Machinery Co.,Ltd. manufacture Full automatic peanut oil making machine making machine using cutting-edge technology, Shandong Leader Machinery Co.,Ltd. have many kinds of 1-20TPD Small Scale Oil Refining Line for you reference,such as Full automatic peanut oil making machine ,Shandong Leader Machinery Co.,Ltd. can meet your different requirement in 1-20TPD Small Scale Oil Refining Line.Welcome to contact Shandong Leader Machinery Co.,Ltd.,contact name:Ms.Myra for a quotation

(Tel/whatsapp:0086-18363092712, Email:[email protected],Skype:leaderfoodmachine2).Welcome to send us your enquiry about capacity for Full automatic peanut oil making machine, inform us raw material you want to use for Full automatic peanut oil making machine,and specific requirements for Full automatic peanut oil making machine.Shandong Leader Machinery Co.,Ltd. will provide you best solution for your project about 1-20TPD Small Scale Oil Refining Line.