According to the difference of alkali thickness and oil temperature for 1-20TPD Small Scale Oil Refining Line, the process of dealkalizing of Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine is divided into two types, one is low temperature with thick alkali (its initial temperature is 20 ~ 30 ℃, alkali thickness is 20 ~ 30 Be) and another one is high temperature with light alkali (its initial temperature is 75 ℃, alkali thickness is 10 to 16 Be). The former of Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine is generally applied and the latter of Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine is mainly used for crude oil which has low acid value, light clour and lustre, and less impurity.

Specifications of 1-20TPD Small Scale Oil Refining Line:

1. soy lecithin

2. suite for soybean, corn germ, peanut, sesame, rapeseed, rice bran, cottonseed, tea seed, sunflower seed oil press

3. pure oil, edible oil quality

4. various capacity:10t/d, 20t/d, 30t/d, 40t/d, 50t/d, 60t/d, 70t/d, 80t/d,100t/d, 150t/d

5. used for hot and cold press

Product Description of 1-20TPD Small Scale Oil Refining Line:

1. What is the Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine?

Raw material→Materials dosing →Magnetic separation→Cleaning→crusher→flaker→ Extrusion Puffing →Counter-current drying→To leaching plant

2. What is 1-20TPD Small Scale Oil Refining Line?

Material embryos→Extraction→Wet meal→Evaporation→Cooling→Product meal packing

↓

Mixed oil→Filter→Negative pressure evaporation → Crude oil→Solvent recovery

Shipping of Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine:

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door,

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving,

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms of Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine:

1. Payment: T/T, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery,

2. MOQ: 1pcs,

3. Warranty : 3 year

Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine

NO.1 Product Description

FFB reception stationâ Sterilization station â Threshing station â Digesting stationâPressing station

â

Nut dryingâ Kernel crushing â Kernel&Fiber separation âCrushing âPalm cake

â

Nut oil pressing âFilterationâCrude palm kernel oil

hot water

â

Crude oil âfilterâmixâreactorâmixâreactorâcentrfugal separationâoil residue

â â

phosphoric acid â

degumming oil âdryâheat â¹ââââââââ

â

bleaching earth âmixâdecoloringâfilterâdecoloring oilâmixâheat

â

refined oil âfilterâcoolâdeodorizingâvacuum

a. Palm fruit reception:Transport FFB to reception station, flow to the scraper conveyer, conveyed to sterilizing station.

b. Sterilizaiton: FFB transported by scraper conveyer fall into sterilizing tank, make FFB soft,get more oil yield. sterilizing time 90~120mins, temperature 130~145°C

c.Threshing: After sterilizing, fruit bunch transported to thresh machine, separate palm fruit and empty fruit bunch.

d:Digesting: Before press palm fruit, should be crushed separated pulp and kernel

e.Oil press: After crushing and digesting, the maxture of palm fruit and kernel fall into special palm oil presser

f.Clarification:Filter the oil and use centrifuge to separate oil and impurities.

g. Kernel recovery:After press, the kernel and cake will be transported to kernel recovery station. Separating nut and shell, then go to kernel oil press

h.Palm kernel oil filteration: Use vibrating filter to filter the oil to remove impurities in it

Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine

The specification of crude palm oil

Item |

Standard |

Smell and taste |

The original smell and taste of crude oil |

Moisture and volatile matter (%) ⤠|

0.20 |

Insoluble impurities (%) ⤠|

0.20 |

Acid value (mgKOH/g) ⤠|

4.0 |

Peroxide value (mmol/kg) ⤠|

7.5 |

palm oil rdfine project

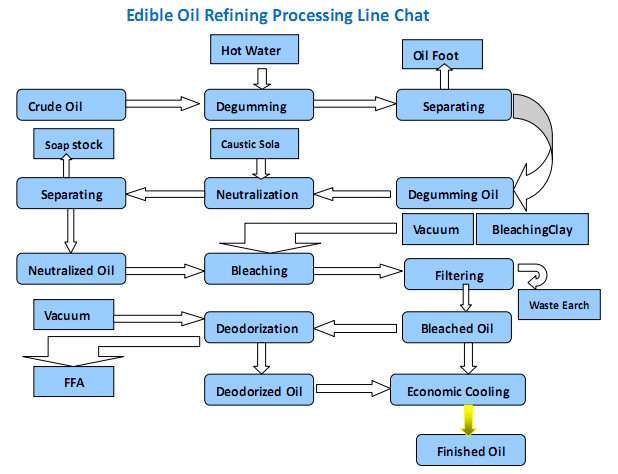

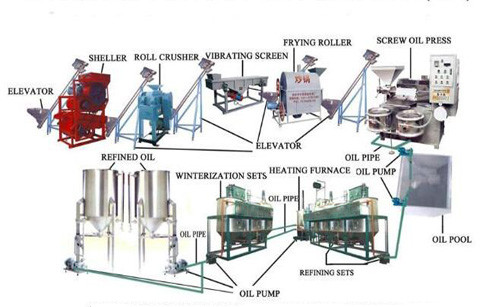

(1) Refining section: used to P-acid de-gumming, alkali refining de-acid and water rinsing.

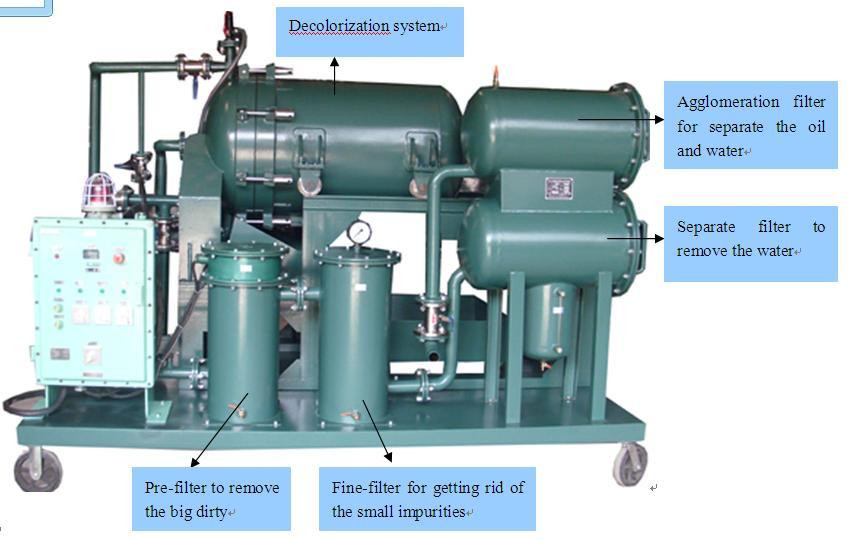

(2) Decoloring section: used to remove off pigments, bleaching oils and grease dehydrate.

(3) Deodorizing section: to remove off the odor components in oil.

(4) Dewax: used to remove off the wax in the oil, in order to get the high quality oil.

(5) Heat-transfer oil stove: supply each device production needing heat energy, temperature reach

above 280°C.

(6) Steam generator: produce the needing steam for de-odoring and distillation.

(7) Vacuum pump: supply needing vacuum for dehydrate, de-color, deodor. Vacuum degree can

reach above 755mm Hg.

(8) Press filter: filter clay, filter out clear oil.

(9) Air compressor: blow dry bleached clay, blow empty the leftover oil in the press filter

Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine

The specification of refined palm oil

Item |

Standard |

Color (Lovibond Cell 133.4mm) ⤠|

R2.0 Y20 |

Smell and taste ⤠|

No smell and good taste |

Transparence ⤠|

Clear and transparent |

Moisture and volatile matter (%) ⤠|

0.05 |

Insoluble impurities (%) ⤠|

0.05 |

Acid value (mgKOH/g) ⤠|

0.20 |

Peroxide value (mmol/kg) ⤠|

5.0 |

Smoke point (°C) ⥠|

215 |

NO.2 Our company

Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine

(1) company information

Jinan Best Grain and Oil Machinery Engineering Co., Ltd(hereinafter referred to as BEST) is specialized in undertaking turnkey projects covering Edible Oil Equipmentmt, Flour Milling Equipment, Feed Equipment and other related machineries. BEST is engaged in designing, manufacturing, supply and installation and commissioning of a complete range of machinery/plants on a turnkey basis. The company offers customized turnkey solutions to the clients right from the very begin planning to commissioning and maintainance.

We are dedicated to supplying safer, more reliable and more environmental-friendly grain and food processing equipment and engineering services that create value for the clients. And our vision is to grow into a globally respectable market leader in its field.

(2)scope of business

â¢Grain Processing Machinery

10-1000TPD wheat flour factory

10-1000TPD corn flour factory â

10-500TPD rice mill and rice flour mill

10-500TPD Corn grits processing machinery

Sorghum dehulling and milling plant

Soybean dehulling production line

Cereals processing machinery

Grain silos and drying equipment

â¢Edible Oil Machinery

Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine

5-3000TPD some major oils production line

Pre-treatment of major seeds line

100-3000TPD Solvent extraction plant

10-1000TPD Oil refining production line(physical and chemical)

20-3000TPD Dewaxing plant(sunflower seed oil, rice bran oil and corn germ oil)

Feed Processing Machinery

Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine

10-500TPD Premix feed production line

10-500TPD Pig feed production line

10-500TPD Livestock feed production line

10-500TPD Aquatic feed production line

10-500TPD Cattle and sheep feed production line

(3)Our service

Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine

1.Our products have the high quality and high performance.we use the stainless steel instead

of the carbon steel.

2. We buy directly from the manufacturer for guaranteeing the quality.

3.Our welding worker should get the certificates.

4.Our electric machines all imported from Germany, like Simens motors

NO.3 client visit:

Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine

We have a solid strength, to ensure the quality, professional after-sales, won the trust of customers around the world.The following are some of our customers come to buy equipment to visit the experimental operation of photos :

In order to protect the privacy of customers, other customers pictures inconvenience display.

NO.4 contact Me:

Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine

Shandong Leader Machinery Co.,Ltd. value "honesty, innovative and quality" because Shandong Leader Machinery Co.,Ltd. know that Shandong Leader Machinery Co.,Ltd. are not only supplying equipment to our clients but the partners to help our clients to get a better result.Keeping this in our mind,Shandong Leader Machinery Co.,Ltd. not only make high quality food processing equipment, but also help the clients to figure out the optimum processing work flows,make amendments according to client's specific needs,training staffs for the user of our equipment and even more, because Shandong Leader Machinery Co.,Ltd. believe that our users or clients' success is the foundation of ours.

Shandong Leader Machinery Co.,Ltd. is one of the leading Manufacturers and Suppliers of Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine.Shandong Leader Machinery Co.,Ltd. manufacture Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine making machine using cutting-edge technology, Shandong Leader Machinery Co.,Ltd. have many kinds of 1-20TPD Small Scale Oil Refining Line for you reference,such as Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine ,Shandong Leader Machinery Co.,Ltd. can meet your different requirement in 1-20TPD Small Scale Oil Refining Line.Welcome to contact Shandong Leader Machinery Co.,Ltd.,contact name:Ms.Myra for a quotation

(Tel/whatsapp:0086-18363092712, Email:[email protected],Skype:leaderfoodmachine2).Welcome to send us your enquiry about capacity for Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine, inform us raw material you want to use for Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine,and specific requirements for Environmental protect oil refinery production line / palm oil refinery plant/ peanut oil refinery machine.Shandong Leader Machinery Co.,Ltd. will provide you best solution for your project about 1-20TPD Small Scale Oil Refining Line.