Shandong Leader Machinery Co.,ltd. have engaged in Oil Refinery Equipment and Microwave Equipment since1997 in China,with 20 years` experience and 80 engineers,, scientific research, manufacturing, installation, commissioning.We can provide customers with design and services of 1-2000 tons oil equipment.factory occupied area is over 100,000 square meters,more than 3200 customers all around the world, we greatly hope to have the opportunity to serve you.

We have finished hundreds of successful projects over the years: peanut oil, soybean oil, rapeseed oil, cottonseed oil, sunflower oil, sesame oil, animal oil,grape seed oil, acer truncatum oil, peony seed oil, walnut oil, hemp seed oil, pine oil, tea seed oil, papaya oil, milk thistle seed, and other special type oil.We have independent import and export department. Our equipment has been successfully exported to more than 100 countries: Russia, Australia, India, Afghanistan, Cameroon,and so on.

Continuous process belt type mushroom dryer machine

Product Description

Item |

Description |

Item Name |

BODA five-layer hot air continuous mushroom dryer machine |

Type |

BDHD-F-12 |

Overall Dimension |

12000×2000×2100(h)mm |

Drying Chamber |

An independent hot air circulation unit in every two meters |

Transmission |

Chain Drive |

Mesh Belt Specification |

W=1800, mesh hole size 10×16mm (Different hole size belt will be used according to materials size), mesh diameter 1.2mm, Material SUS304; Roller 12mm round steel, Interval 150mm, Material SUS304; Chain interval 38.1mm, roller diameter 22.23mm, thickness 3mm, Material 201 |

Mesh layer |

Five layers |

Motor Power |

3kw stepless variable speed motor + frequency control |

Transmission Speed Range |

0.3~5m/min,(time 30~300min) |

Fan |

DLF4.5C low noise centrifugal fan |

Fan Parameter |

4kw×6 sets, air volume 12500-6500m³/h,motor power 4kw, rpm 900 r/min, full pressure 830Pa |

Heating Source |

Steam exchanging heat, steam pressure 0.4~0.6MPa |

Heat Exchanger |

SRZ5×5D×6 sets, stainless steel composite aluminum fin tube, heat exchange area 120 square meter |

Steam Consumption |

600~800kg/h |

Input Power |

≤35kw |

Drying Temperature |

0~80℃,temperature tolerances ±3℃ |

Heating Mode |

Hot air circulation heating and flow through heating |

Control System |

PLC control, touch screen, automatic temperature control, transmission control, air volume control, video monitoring, fault display etc |

Feeding |

Automatic distribute material,evenly distribution,thickness adjustable |

Feeding Port Size |

H=3500mm,W=2000mm |

Discharging Port Size |

H=600mm,W=2000mm |

Door |

Stainless steel appearance |

Working Voltage |

380V 3 phase |

Relative Humidity( ℃) |

≤85% |

Environment Temperature ( ℃) |

Seasonal Temperature |

Temperature Requirement |

Should be no excessive corrosive gas,no inflammable and explosive gas around |

Site requirements |

Smooth and flat cement floor |

Usage:

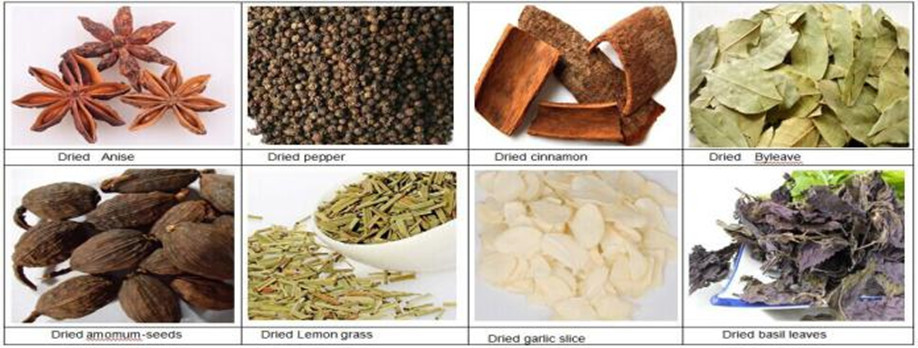

The hot air ginger drying machine is used for drying mushroom, mushroom slices, gingers, onions and all kinds of fruits, vegetables, spices, etc.

It is designed for mass process quantity to achieve automatic continuous production. Single layer or multi layer mushroom drying machine will be customized according to your requirements.

Packaging & Shipping

Packing & Shipping:

1 set of hot air mushroom dryer machine are fit for a 40GP.

Wooden pallet or other packing will be used, supported with soft packing to prevent shift of mushroom drying machine in container.

Our Services

LD provides a full range of services and technical support for industrial mushroom hot air drying machine. The services include custom installations, preventive equipment maintenance, equipment upgrades and modifications and drying system repair.

Company Information

Company Information:

LD

You are here: Home >> Conti Dryer >> Continuous process belt type mushroom dryer machine

Continuous process belt type mushroom dryer machine has been used in many herbal extraction production lines, such as kudzu, tea, silver leaf and licorice.Microwave assisted extraction has been listed as one of China's 21st century food processing and pharmaceutical modernization promotion techniques.Compared with the usual extraction method, the extraction time was only 3 minutes and reduced by 20~100 times.

AAA1

What is the characteristic of Continuous process belt type mushroom dryer machine?

1.Equipment effect at once, power adjustable, transmission speed adjustable, no thermal inertia residues, compare with the convenentional process equipment to save energy by 50%;

2..Make the material itself become body heat source state, owing without heat transfer process, it can achieve the drying teperature within a very short time;

AAA2

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: [email protected]