Shandong Leader Machinery Co.,ltd. have many years of export experience about Microwave Drying And Sterilizing Equipment. We have excellent quality control staff and well-trained technicians. Through constant technical exchanges with well-known peers in the same industry and the introduction of advanced management modes, the company has established a strong quality assurance system.

From the beginning, our company has always insisted on the pursuit of excellence and business philosophy, and customers common development purposes. In our management, in a wholehearted attitude, a good reputation, good quality, perfect service, sales and after-sales service principles. So we won a great reputation and reputation among our clients.

Shandong Leader Machinery Co.,ltd. on the basis of the domestic market, open up the international market, the establishment of a global sales network. Shandong Leader Machinery Co.,ltd.'s Microwave Drying And Sterilizing Equipment is marketed well throughout China and is also exported to Southeast Asia, Europe, Africa and other foreign countries and our market share is increasing every year.

Microwave Drying And Sterilizing Equipment Overview:

Shandong Leader Machinery Co.,ltd.'s Food processing industrial vacuum microwave fryer is mainly used for food and drug sterilization. Bacteria contain large amounts of water molecules in the body, under the action of Food processing industrial vacuum microwave fryer, quickly interrupt the biological chain, a minute or two bacteria can be killed. It was determined that sausages containing 1.92 million E. coli per gram were heated in a 500-watt microwave oven and survived 260 per gram after a half-minute and all were killed after 1 minute. Food processing industrial vacuum microwave fryer is to heat the object itself becomes a heating element, the process does not require heat conduction. Microwave penetrates the inside and outside of the object from all directions at the same time make the object in a very short period of time to achieve uniform heating and sterilization, greatly reducing the drying sterilization time, which can improve the yield. Practice has proved that the use of microwave sterilization generally kill all E. coli at 70 ℃, 80 ~ 90 ℃ greatly reduce the total number of bacteria, the time just 2 to 8 minutes. Fast, short time, so retain the nutritional content of food, the traditional flavor.

Food processing industrial vacuum microwave fryer Technical parameters:

1, Input Power: Three-phase five-wire 380V ± 10% 50Hz ± 1%

2, microwave output power: 30kW (adjustable)

3, microwave frequency: 2450MHz ± 50Hz

4, rated input apparent power: ≤ 45kVA

5, out of the mouth height: 50mm

6, the transmission bandwidth: 650mm

7, the transmission speed: 0.1 ~ 5m / min

8, Dimensions (L × W × H): about 11630 × 1310 × 1668mm

9, working environment: 0 ~ 40 ℃, relative humidity ≤ 80%

10, Food processing industrial vacuum microwave fryer production: dry dehydration 30kg per hour

11, in line with GB 10436-1989 workplace microwave radiation health standards

13, in line with GB / 5226.1-2002 mechanical safety machinery and electrical equipment

Product Description

Introduction of Food processing industrial vacuum microwave fryer:

This machine fits for drying and sterilizing powders, granular, sheet-like or gel-like food, and additive, spices, flavoring, medicine, raw material of herbal medicine, nutritional health products, agricultural & sideline products, non-fired(or oil saving)instant noodles, noodles, rice powder needles, soy products, beef jerky, preserved meat, dried fish, tea, tobacco and so on; and for drying, peeling and baking almond, peach kernel, groundnut kernels, chestnut and so on; and for puffing of leisure food, pachyrhizus chips, potato chips, dried shrimps, fish maw and so on; and for thawing the frozen fish, poultry; and for drying beans; and for drying and desulfurating and deoxidizing the metallurgical chemical products; and for drying printing and dyeing products, ceramics, glass, chemical fiber, cotton yarn, wood, leather, bamboo products, insulation materials, building materials, wood , cork, alveolate, cardboard,corrugated cardboard, and so on.

Features of microwave tunnel dryer:

1.Sterilization and drying at the same time.And the dryness of dried flowers is uniform.

2.The microwave dryer for red chili never change and break the nutritional facts.

3.Owing to short time of drying,it can maintain more original fragrance.The smell is more delicious than traditonal ways.

4.After the microwave drying,the products can meet with QS health standard owing to the reduced bacteria rate.

5.The microwave drying type microwave dryer has advantages of less occupied area,driven by electricity motor.So it can protect environment and save energy.

6.Improving the value of the red chillies and other vegetables and save drying cost.

Specification of vacuum microwave fryer:

Note: The above technical parameter should prevail by the product operating manual ,specific parameter will very according to your different customization needs.

Usage: Microwave Vacuum Dryer is used for drying all kinds of herbs, including raw herbs, herb powders, herb pellets, etc

Branded parts:

Branded parts:

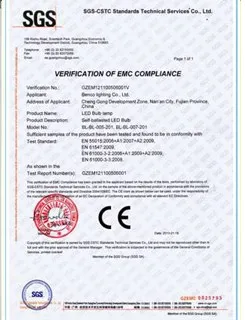

Certifications

Certifications

Detailed Images

Detailed ImagesFeatures of machine parts:

Our Service

Our Service

Services Of Microwave vacuum Dryer:

Pre-sale services:

Act as a good advisor and assistant of clients; enable them to get rich and competitive

from the returns of their investment.

1) Select suitable equipment model.

2) Design and manufacture products according to clientsâ special requirements.

3) Train technical personnel for clients.

4) Professional suggestion for customer

Services during the sale:

Respect clients; devote ourselves to improving the total value of clients.

1)take photos(including raw material, semi-products, final products, and loading products)

1) Pre-check and accept products ahead of delivery.

2) Prepare all clearance documents, so that the customer clearance smoothly.

After-sale services:

Provide considerate services to minimize clientsâ worries.

1) Provide civil engineering drawings of the equipment.

2) Free training(including installation,maintenace) to every customer.

3) Install and debug the equipment, ensure the dryer running smoothly.

4) Examine the equipment regularly.

5) Take initiative to eliminate the troubles rapidly at site.

6) Distribute the guarantee fittings door-to-door.

7) Provide technical exchange and support.

8) Provide maintenance for big items.

9) The most preferential prices to provide customers the quick-wear parts.

Packaging & Shipping:

1).Packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film.Finaly pack them with wooden case.

2)Customer's requirement is available.

3).If you want to know the transportation cost: by air-please tell me your airport name; by express-please tell me your detailed address(including zip code,house number,street,city,country); by ship-pls tell me your delivery port.

For any further information, pls do not hesitate to contact us!!

Best regards!!

Good luck to you!!Related Products

Corn flakes making line

98.8% Response Rate

Puff snacks making line

99.5% Response Rate

Baby food making machine

99.1% Response Rate

Delivery:

Small machine, we support TNT, DHL, FedEx,UPS.

Big machine, we support delivery by ship.

We can also deliver the machine to your agent in china if you have.

Warranty

1. We guarantee the item is “Brand New”, never been used and in perfect working condition.Every item will be tested carefully before shipping out.

2. Sometimes due to the mishandling in transportation, some parts may loose, the machine will not work properly.In this case, please be patient, we will tell how to do it.

3. How to deal with product damage: if the package arrives in bad condition, please take packaging pictures before unpacking, and check the goods in front of the staff of shipping company, in case it is damaged in transportation due to rude handling. Contact us within 3 days if the product damaged, and please allow time for us to handle with the problems, we will try our best to solve it.

Our service:

1.Machine will be adjusted well before delivery

2.One year warranty:Free replacement of main parts during warranty period.

3.Sending you the user manual for machine installation and operation

4.Free traning and technical support

5.24 hours at your service

Welcome to enquiry!

Our company has engaged in producing and exporting Food processing industrial vacuum microwave fryer for many years, and until now, our machine has exported to overseas market, such as Brazil, India, Indonesia, Russia, Thailand and so on, and get the foreign customers' unanimous praise.

Shandong Leader Machinery Co.,ltd. equipment installation, commissioning of the date of the beginning, 12 months for the quality of warranty, life-long technical services. As the equipment is non-standard equipment, the above is for reference only, welcome new and old customers call us or visit our company directly to discuss cooperation.

We believe that you purchase Shandong Leader Machinery Co.,ltd. Food processing industrial vacuum microwave fryer is your best and sensible choice.

CONTACT:MISS ANNA

TEL: +86 0531 85064681

PHONE: +0086 15764119982(ALSO WHATSAPP & WECHAT)

EMAIL:[email protected]

SKYPE: LEADERFOODMACHINESALES6