Shandong Leader Machinery Co.,ltd. has finished hundreds of successful projects over the years: peanut oil, soybean oil, rapeseed oil, cottonseed oil, sunflower oil, sesame oil, animal oil,grape seed oil, acer truncatum oil, peony seed oil, walnut oil, hemp seed oil, pine oil, tea seed oil, papaya oil, milk thistle seed, and other special type oil.We have independent import and export department. Our equipment has been successfully exported to more than 100 countries: Russia, Australia, India, Afghanistan, Cameroon,and so on.

Product Description:

According to customers on the type of oil, daily processing volume, oil standards and other conditions of the requirements of processing customization, size, refining the number of cans, product prices are different.

microwave oven/dehydrator food dryer

Product Description:

Model number |

BDMD- F-P-60 |

Description |

LD Microwave chilli drying machine |

| Microwave frequency (MHz) | 2450±50 |

| Input voltage | 380V, 50Hz |

| Microwave power(KW) | 60 |

Chamber material |

Stainless steel |

| Chamber color | Silver-white |

| Conveyor belt | PTFE |

| Dryer dimension(L*W*H)(mm) | 11.0x1.1x1.7 |

| Weight (KG) | 3500 |

| Microwave leakage limit(mW/cm2) | 1 mW/cm2 |

| Relative humidity(℃) | ≤85% |

| Ambient temperature(℃) | Normal temperature |

| Environment requirement | No excessive corrosive gas, no inflammable, explosive gas |

Usage:

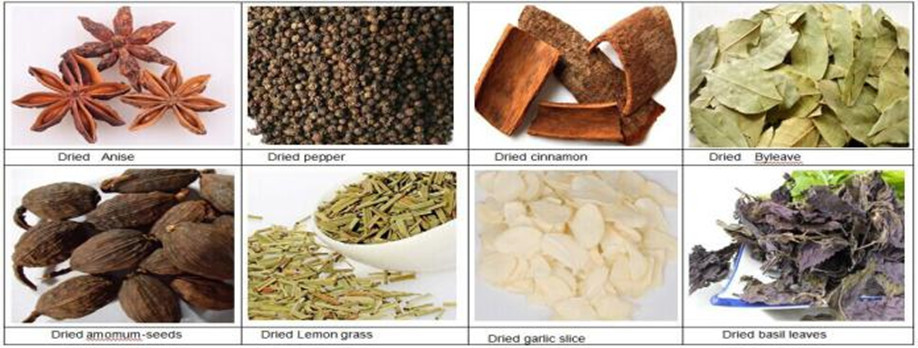

Microwave chilli drying machine is used for drying black pepper, white pepper, red chilli, chilli powder, turmeric, pepper, curry powder, ginger, garlic, scallion, onion, etc.

Advantage:

Microwave red chilli drying machine has a number of quantitative and qualitative advantages over conventional drying techniques that make its adoption a serious proposition. One main advantage is the place where the heat is generated, namely the product itself. Because of this, the effect of small heat conductivities or heat transfer coefficients does not play such an important role. Therefore, larger pieces can be heated in a shorter time and with a more even temperature distribution. These advantages often yield an increased production.

- Energy saving 30%-60%

- Drying speed 50% quicker

- Reduced CO2 emissions

- Increased manufacturing efficiency and throughput

- Drying temperature adjustable

- Suitable for drying spice and condiment powder, granules, and other shapes

Packing & Shipping:

Wooden packing for each set of whole chilli industrial microwave drying machine

Soft packing is supplied.

Our Services:

LD provides a full range of services and technical support for industrial microwave systems. The services include custom installations, preventive equipment maintenance, equipment upgrades and modifications and microwave system repa

Company Information

FAQ:

1. What is Microwave?

Microwaves are a form of electromagnetic energy with frequencies between 300 MHz and 300 GHz, generated by magnetrons under the combined force of an electric and a magnetic field perpendicular to each other.

2. What is the advantage of Microwave dryer compare to Conventional dryer?

Conventional dryer is a surface drying method, which is not only slow, but also non-uniform with the surfaces, edges and corners being much dried than the inside of the material. The imperfect drying will cause product rejections, waste energy and extend process time.

Microwave dryer is a direct method of drying. Energy is transferred through the material electro-magnetically, not as a thermal heat flux. Therefore, the rate of drying is not limited, the uniformity of heat distribution is greatly improved and drying time is reduced.

3. How about safety?

Using scientific structure and patented suppression system, LD industrial microwave dryer poses no threat of electromagnetic radiation to the health and safety of equipment operators.

4.What about maintenance?

In addition to downtime for cleaning and inspection, conventional dryers and heat exchangers need periodic servicing with an expensive inventory of parts and a highly trained labor force. For microwave dryer, the only part that requires maintenance is the magnetron. In the event of a malfunction or misuse through incorrect operation, this can easily be replaced in less than thirty minutes. Generally, LD recommends that the magnetron of industrial microwave dryer be replaced annually or after 8,000 hours of operation, whichever is sooner.

Bay leaf/myrcia/condiment/spice microwave dryer and sterilizer

Factory production equipment

WHY CHOOSE US

1:CHINA BIGGEST FACTORY .

2:Supply spare parts according to order quantity.

3:Technical support for your installation, operation and maintenance.

4: Lifetime warranty

5: Fast delivery

6:Provide with CCC CE ISO certificate

7: we can customize different dimension and Specification according to the requirements of customers.

If you are interested in our machine,please contact us for more information (such as catalogue,video,prices,etc).

microwave oven/dehydrator food dryer is an electromagnetic wave whose frequency is between 300MHZ~300GHZ and wavelength is between 1mm ~1m. the characteristics of microwave usually shows penetration, reflection and absorption . For glass, plastic and porcelain, microwave will penetrate it without being absorbed. For water and food, it will absorb microwave and heating by itself. For metal material, it will reflect the microwave.

AAA1

Microwave drying : Water molecule is polar molecule, it will change its polarity and friction motion caused by the effect of high speed change of high frequency electormagnetic field. Then the microwave electromagnetic filed energy can be converted into heat energy and achieve the purpose of drying. Due to the strong penetrability, microwave oven/dehydrator food dryer can heat up the material outside and inside simultaneously and evenly, so that won't appear the condition that the outsie dry but inside wet. The formation of body heat source state shortens the time of heat conduction and save a lot of drying time.

AAA2

Microwave sterilization:microwave oven/dehydrator food dryer temperature is from 70℃~105℃, period is from 90 seconds ~180 seconds. Microwave thermal effects can change the bacterial protein and make bacteria to die owing the loss of nutrients, reproduction and survival.Meanwhile, Microwave eletromagnetic field can make normal growth and stability of the genetic breeding of bacteria nucleic acid.

AAA3

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: [email protected]