The quick wear part of Oil Fractionation Equipment use good quality steel which processing by cementation heat treatment. So this treatment can extend working life, reduce use-cost and maintenance time.Shandong Leader Machinery Co.,ltd. palm oil fractionation equipment vegetable oil solvent extraction plant adopt new type big modulus helical gear transmission, can boost transmission efficiency, reduce energy consumption.Extended barrel of palm oil fractionation equipment vegetable oil solvent extraction plant make the squeezed time longer, boost the efficiency of oil.Shandong Leader Machinery Co.,ltd. 20 years of production experience, 18 years of overseas service system installation. Robust Oil Mill and Oil Refinery Machines designed for minimum Wear and Tear.Oil Fractionation Equipment Totally Steel Fabricated machinery.vegetable oil solvent extraction plant Low Maintenance oil mill machines with high oil productivity.Low Space occupancy of our machines Oil Fractionation Equipment.Continuous Research Development in order to provide best performance vegetable oil solvent extraction plant.Shandong Leader Machinery Co.,ltd. possess a team of experts who source products of international standard to keep abreast with the global markets.Shandong Leader Machinery Co.,ltd. endeavor to provide the best has been acknowledged by our clients both in domestic and international arena.We know vegetable oil solvent extraction plant industry. We know technology. We know how to enhance your success.

Product Description

Company profiles:

LD and oil machinery co., LTD,a leader with 33 years experience ,is a company specializing in the production of and oil machinery and equipment, scientific research, manufacturing, sales for the integration of large-scale private enterprises, the company with the mechanical design and research institute of Shandong province, Shandong university of technology (the former college of food) university-enterprise cooperation, carried out for a long time in oil machinery, preparing protein, lecithin extraction and other aspects of the research and development and application of new technology.

LD and oil machinery co., LTD,a leader with 33 years experience ,is a company specializing in the production of and oil machinery and equipment, scientific research, manufacturing, sales for the integration of large-scale private enterprises, the company with the mechanical design and research institute of Shandong province, Shandong university of technology (the former college of food) university-enterprise cooperation, carried out for a long time in oil machinery, preparing protein, lecithin extraction and other aspects of the research and development and application of new technology.

Detailed Images

Detailed Images

Machine Parts

Name: Pretreatment Plant

Brand: LD

Original: China

Rice bran extrusion flow chart:

Rice branâMagnetic separationâCleaning âExtrusion Puffing âCounter-current dryingâTo leaching plant

Main Features

Name: Cleaning process

Brand: LD

Original: China

Adopt the magnetic separation removing iron miscellaneous and vibration sieve removing broken clear, rice Xi, etc.

Machine Parts

Name: Extrusion process:

Brand: LD

Original: China

Adopting the bulking machine can both improve the yield of rice bran oil and reduce the consumption. The extrusion puffing, on the one hand, can make solution lipase in the rice bran passivated under high temperature and high pressure condition,then prevent the rice bran oil rancidity; On the other hand, the extrusion puffing can make rice bran be porous mateial , and increases the materials bulk density, then improve the permeability and leaching rate which solvent reacts to the material.

Main Features

Name: Drying process

Brand: LD

Original: China

The puffed rice bran contains about 12% water, and the best moisture for leaching process is 7-9%, therefore, there must be effective drying means to achieve the best leaching moisture.Adopting counter-current dryer can make water and temperature meet with follow-up process requirements, and improve the oil yield, as well as oil quality.

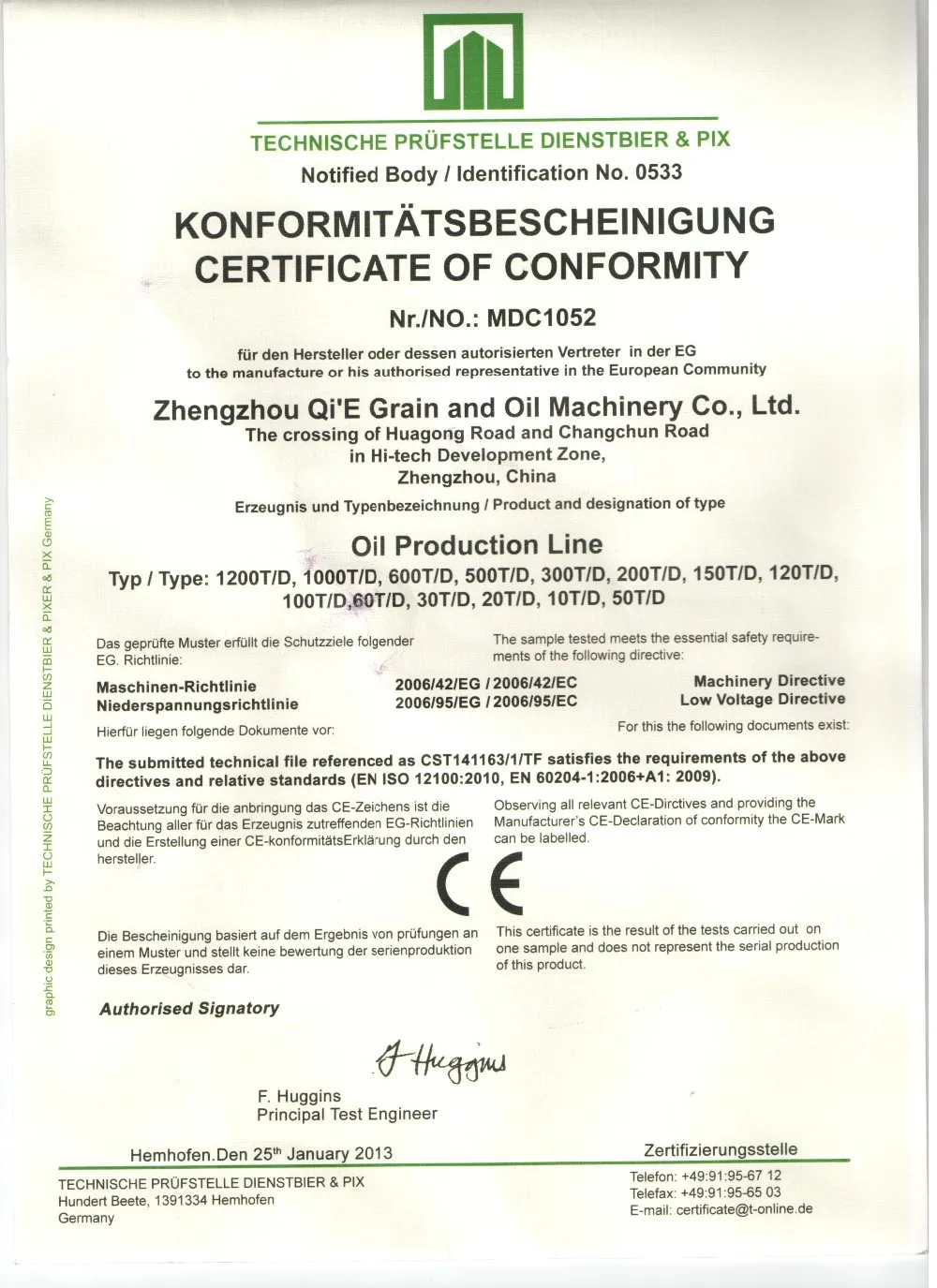

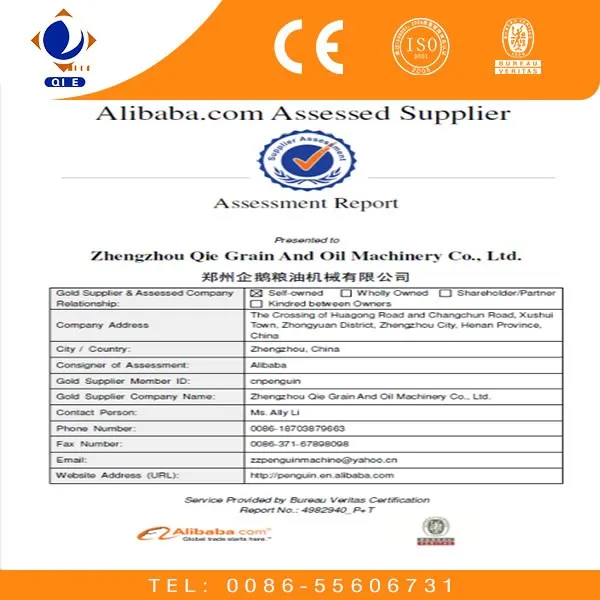

Certifications

Certifications

Our Service

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing amp; Delivery

Packing amp; Delivery

| Packaging | |

| Size | 123 (L) * 456 (W) * 789 (D) |

| Weight | 1.2 T |

| Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

| Packaging | |

| Size | 123 (L) * 456 (W) * 789 (D) |

| Weight | 1.2 T |

| Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Contact Us

Please send the inquiry to me, waiting for your coming to China and visit our plant.

Shandong Leader Machinery Co.,ltd. the crude oil is output by the oil feed pump from the Oil Fractionation Equipment oil tank, and next enters the crude oil heat exchanger to recover part of heat after metering and then is heated to the required temperature by the heater. After that, vegetable oil solvent extraction plant the oil is mixed with the metered phosphoric acid or citric acid from phosphate tank in the gas mixture (M401), and vegetable oil solvent extraction plant then enters the conditioning tank (R401) to make the non-hydratable phospholipids in oil change into the hydratable phospholipids. Shandong Leader Machinery Co.,ltd. Add the alkali for neutralization, and the alkali quantity and alkali solution concentration depend on the quality of the crude oil. Through the heater, Oil Fractionation Equipment the neutralized oil is heated to the temperature (90°C) suitable for centrifugal separation to remove the phospholipids, FFA and other impurities in the crude oil. Then the Oil Fractionation Equipment oil goes to the washing process.Oil Fractionation Equipment there is still about 500ppm soap in the neutralized oil from the separator. To remove the remaining soap, vegetable oil solvent extraction plant add into the oil about 5~8% hot water, with water temperature 3~5 °C higher than the oil generally. To achieve more stable washing effect, add phosphoric acid or citric acid when washing. Shandong Leader Machinery Co.,ltd. The re-mixed oil and water in the mixer is heated to 90-95°C by the heater, and then enters the wash separator to separate the remaining soap and most water. The water with soap and oil enters vegetable oil solvent extraction plant into oil separator to separate out oil in the water. Further catch the oil outside, and the waste water Shandong Leader Machinery Co.,ltd. is discharged to the sewage treatment station.

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

Email:[email protected]

Whatsapp:+86 13064099546

Skype:leaderfoodmachine21

Contact:Mandy

NOTE:We can specially design the machine according to your production's features.