Shandong Leader Machinery Co.,ltd. are a professional manufacturer of Conveyor belt continuous microwave drying sterilizing machine for rice for 20 years. Our main products includes Block making machine, concrete mixer, dry mortar mixer, charcoal machine, Coal briquette machine, Wood Crusher, Oil press machine, Biomass briquette machine, food machinery, etc.

With 20 years exporting experience, Shandong Leader Machinery Co.,ltd. are now the leading supplier in middle China now, our products has been exported to more than 100 countries in the world. Clients profits go first is our principle. We have good faith in working with you and we are sure Shandong Leader Machinery Co.,ltd. team is one of your Choices in China.

Conveyor belt continuous microwave drying

sterilizing machine for rice

Biref introduction

1, the drying and moulding quality is quite good and cannot be cracked.

2, Easy to control and operate. It can control the heating and drying time automatically.

3, Saving time and high production.

4, Energy consuming little

5, Production intensity and space is little

6, Saving labour and procedure, especially it's easy to connect automatically with before and after procedure. And reduce and carring time.

7, Clean and protecting environment. No pollution and cannot bring "three wastes" question

Application

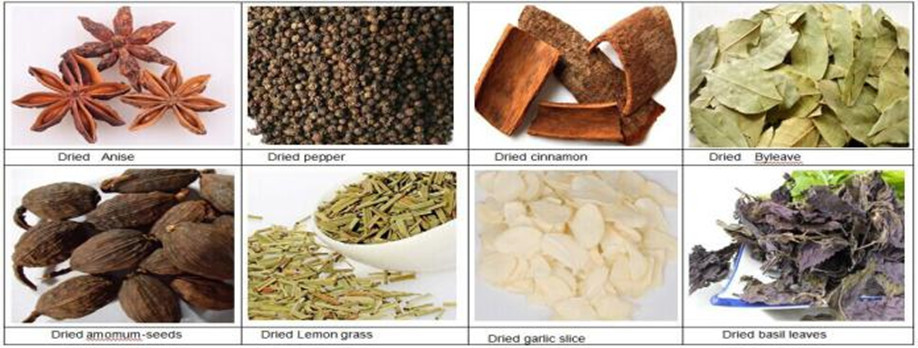

This equipment are widely used for drying and sterilizing powder, granular, flakes or colloidal form foods, nutritional health products, , agricultural and sideline products(rice, cornmeal), bamboo shoot, tea(wild chrysanthemum flower, broadleaf holly leaf, lotus leaf, green tea, black tea, puer tea), ginseng, mushroom, agaric, ganoderma, vegetables and fruits(spinach, carrot, parsley, onion, mango slice, apple slice, lemon slice, kiwi slice, banana slice etc.), preserved fruits, red jujube, non-fried(oil saving) instant noodles, noodles, cookie, biscuit, rice powder noodles, chicken jerky, beef jerky, preserved meat, dried fish, seafood(seaweed, sea cucumber, laver, kelp, sardine, shrimp, abalone etc.), pickles, spices(pepper powder, Chicken essence, beef essence, pork essence, yeast extract, seafood extract, seafood soup essence, seafood soup powder, spareribs soup pure, spareribs soup powder, spice, chili powder, ginger powder, garlic powder, aniseed, cinnamon, angelica, cumin, cassia bark, fennel etc.), egg yolk powder, jam, a variety of small packaging and pet food miLDw sterilization preservation.

The principle of microwave drying

Microwave is a sort of electromagnetic wave which frequency is 300MHz to 300GHz .The water molecule in medium materials is polar molecule,under the effect of the rapid change of electromagnetic field,its polarity orientation will alter with the changes of the external electric field with the high-speed,causing the movement and friction of molecule.so that the microwave field energy can be converted to heat energy in medium to rise the temperature of materials.accomplishing heating ,puffing and a series of physical and chemical processes ,and so ,microwave heating is achieved.

Microwave sterilization principle

Microwave sterilization equipment is to use the combination of microwave heating effect and biological effect.

Microwave effect on bacteria in the cross section of the membrane potential distribution around the cell membrane

electron and ion concentration, which change the membrane performance, fully bacteria so malnutrition, cannot

normal metabolism, growth hindered the death.

In addition, the microwave can make normal bacteria growth and stable genetic breeding of nucleic acid (RNA) and deoxyribonucleic acid (DNA), is by the number of hydrogen bonding is flabby, faults and restructuring, and thus

induce genetic mutations, or chromosome aberration and even rupture.

Technical parameter

Power supply |

380V±10% 50HZ±1% three-phase five-wire |

|

Microwave Output Frequency

|

2450±50MHz |

Microwave input apparent power |

42KVA |

Microwave output power |

30KW |

Microwave power adjustment range |

0-30KW(adjustable) |

Ambient temperature |

-5-40°C |

Dehydrate |

30-42kg/h |

Relative humidity |

80%, Surrounding environment:no corrosive gas, conductive dust and explosive gas |

Overall dimension(L*W*H) |

10500*1440*1750 mm, can be customized |

Transmission speed |

0-10m/min(adjustable) |

Height of the inlet and outlet |

60 mm |

Microwave leak |

accord with a country GB10436-89 standards( |

Equipment safety |

accord with GB-5226Electrical safety standard accord with a country GB16798-1997 Food machinery health security index |

We also can design a suitable model for you according your requirements.

Our guranteen and after-sales service

For the whole equipment, warranty is 12 months, within 12 months, if have equipment quality problems, we will

provide accessories freely. After the expiration of the warranty period, if have spare parts problem, we only receivethe cost of required replacement parts. We commit we will provide free technical support of equipment all whole

life.

Design for machine

1.Transmission System:

a. Speed of Conveying belt is adjustable.

In the transmission system, it applies frequency-converting control of speed, worm gear reducer.

b. The conveyor belt is Teflon Belt,special for microwave.

c. The deviation of belt is adjusted with Hand-movement.

2. The body of the Tunnel

a.The body of the microwave tunnel is made of Stainless Steel. In side there is one set of humidity extraction system to extract the humidity after heating.

b. To be safe, there is Automatic Power-off device while open the door of the machine.

c. The protecting case of Magnetic-pipe and transformer is made of stainless steel. On top there is one set of Heat extraction system to extract the heat energy generated by

working of machine.

d.The frame of machine is made of Stainless Steel pipe ,others is made of cold-rolled sheet painted.

e.One set of infrared thermometric is installed at the outlet of the tunnel to measure the temperature.

3.The controlling system

a. On the outside panel there are frequency converting speed controller, emergency stop button, Start, Stop buttons,

b. All the controlling components will be installed into one controlling box, which is at the entrance of the machine.

c.Ordinary button control system,.

d.The microwave power can be adjusted by choosing in the display text.

e. Every microwave source is an independent unit.If one is broken, the machine will not be prevented from running.

f. Every magnetron has an overheating protection device.

Picture

Conveyor belt continuous microwave drying sterilizing machine for rice, often colloquially shortened to microwave, is a kitchen appliance that heats food by bombarding it with electromagnetic radiation in the microwave dryer spectrum causing polarized molecules in the food to rotate and build up thermal energy in a process known as dielectric heating.Conveyor belt continuous microwave drying sterilizing machine for rice heat foods quickly and efficiently because excitation is fairly uniform in the outer 25–38 mm of a dense (high water content) food item; food is more evenly heated throughout (except in thick, dense objects) than generally occurs in other cooking techniques. Conveyor belt continuous microwave drying sterilizing machine for rice can Sterilize the food during the drying process by heat and the influence on the protein, RNA, DNA, cell membrane and so on.

AAA1

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: [email protected]