Hot air rotary oven Full automatic microwave pumpkin seeds roaster machine can be used by Diesel, gas or electric heating as Shandong Leader Machinery Co.,ltd. energy formation hot air convection circulation, Heavy Duty industrial Commercial microwave oven reach the rotary chart (Rotating platform) inside making the temperature and air inside more even ,operate at high efficiency and regular circulation.Shandong Leader Machinery Co.,ltd. Special designed resistance, air circulation system and prevention of heat loss from chimney, reduce energy consumption and provide to achieve products as desired. Thanks to double-way plate-tube system, high pressure steam Full automatic microwave pumpkin seeds roaster machine is produced and each of the pans is adequately provided with the steam. The steam is prevented from being dispersed in the workshop thanks to the hood and Heavy Duty industrial Commercial microwave oven aspirator over the oven. Chassis, baking chamber and baking chamber cover Heavy Duty industrial Commercial microwave oven is fully made of stainless steel.Shandong Leader Machinery Co.,ltd. Rotary oven are suitable for uniform and perfect baking of various products like bread, buns, cakes and cookie. Widely popular among small to medium bakery businesses and is best suited for bakeries producing number of varieties.

Full automatic microwave pumpkin seeds

roaster machine

Detailed product description

1. High energy conversion efficiency, fast heating, low energy loss

2. Advanced craft, easy to control, fast heating, wonderful baking and puffing effect

3. Microwave baking and puffing simultaneously, along with bactericidal effect

4. Low-temperature baking and puffing, less nutrition loss, puffing without oil, better for health.

Main used area

Microwave industrial tunnel baking&puffing equipment are widely used in the peanut, sesame seeds, wheat, melon seeds, sunflower seeds, peanuts, corn, soybeans, walnuts, almonds, chestnuts, pistachios, cashews, filbert and dried fruit etc; and for leisure food, pachyrhizus chips, potato chips, dried shrimps, fish maw and so on. Compared with the traditional production methods, microwave baked foods are crispy and delicious, products particle puffed full, natural color, beautiful appearance, and has insecticidal sterilization effect.

Microwave roasting features

1. Energy conversion efficiency high, fast heating.

Microwave oven itself, but microwave energy fever, make the material through materials within polarity produced molecular friction between internal heat. Make the liquid inside processed materials instantaneous warming vaporization, boosting inflation; And depend on gas expansion force make component of macromolecule substance, and become a structural degeneration areolar tissue structure characteristics, finalize the design of microporous shape more than substance.

2. when microwave roasting ,sterilization effect at the same time.

Microwave sterilization is in the microwave heating and the dual role of non-thermal effect under the temperature sterilization, compared with conventional in lower temperature and very short time get satisfactory antiseptic effect. General sterilizing temperature around in 80 °C, the processing time in 3 ~ 5 minutes, and to the maximum maintain its nutrients.

3.The operation is convenient.

Microwave power and conveyor belt speed can adjust arbitrary, both thermal inertia, but do not exist, simple, easy to open namely stop control. Improve the production environment. Microwave equipment nirvikalpa radiation, no dust, no noise, no pollution, easy to realize the food hygiene inspection standard.

4. Puffed effect is obvious.

Microwave fast heating effect, make the material internal water molecules, achieve rapid vaporization ,reach to the puffed purpose.

5. Low temperature sterilization, nutrition loss less.

Microwave sterilization is in the microwave heating and the dual role of non-thermal effect under the temperature sterilization, compared with conventional in lower temperature and very short time get satisfactory antiseptic effect. General sterilizing temperature around in 80 °C, the processing time in 3 ~ 5 minutes, and to the maximum maintain its nutrients. The reserves of vitamin C conventional heat treatment fruits and vegetables is 46% ~ 50%, microwave, can reach 60 ~ 90; Keep to vitamin A conventional heat treatment is 58 percent, and microwave treatment is to 84%, and would not affect the original flavor, is the fruit and vegetable food processing, obtain the good means green food.

The features of machine design

1.Transmission System:

a. Speed of Conveying belt is adjustable.

In the transmission system, it applies frequency-converting control of speed, worm gear reducer.

b. The conveyor belt is Teflon Belt,special for microwave.

c. The deviation of belt is adjusted with Hand-movement.

2. The body of the Tunnel

a.The body of the microwave tunnel is made of Stainless Steel. In side there is one set of humidity extraction system to extract the humidity after heating.

b. To be safe, there is Automatic Power-off device while open the door of the machine.

c. The protecting case of Magnetic-pipe and transformer is made of stainless steel. On top there is one set of Heat extraction system to extract the heat energy generated by

working of machine.

d.The frame of machine is made of Stainless Steel pipe ,others is made of cold-rolled sheet painted.

e.One set of infrared thermometric is installed at the outlet of the tunnel to measure the temperature.

3.The controlling system

a. On the outside panel there are frequency converting speed controller, emergency stop button, Start, Stop buttons,

b. All the controlling components will be installed into one controlling box, which is at the entrance of the machine.

c.Ordinary button control system,.

d.The microwave power can be adjusted by choosing in the display text.

e. Every microwave source is an independent unit.If one is broken, the machine will not be prevented from running.

f. Every magnetron has an overheating protection device.

Technical parameter

Power supply | 380V±10% 50HZ±1% three-phase five-wire |

Microwave Output Frequency

| 2450±50MHz |

Microwave input apparent power | 28KVA |

Microwave output power | 20KW |

Microwave power adjustment range | 0-20KW(adjustable) |

Ambient temperature | -5-40°C |

Relative humidity | 80%, Surrounding environment:no corrosive gas, conductive dust and explosive gas |

Overall dimension(L*W*H) | 9400*1440*2050 mm |

Transmission speed | 0-10m/min(adjustable) |

Height of the inlet and outlet | 60 mm |

Microwave leak | accord with a country GB10436-89 standards(<5 mw/cm^2) |

Equipment safety | accord with GB-5226Electrical safety standard accord with a country GB16798-1997 Food machinery health securit index |

Pictures reference

NOTE:We can specially design the machine according to your production's features.

JINAN Microwave machinery equipment Co.,Ltd.

Shandong Leader Machinery Co.,ltd. Apply for baking of food and goods with chemical gas ,removal of the substrate,curing of the lnk and dryingoffilm and so on. Widely used in the precision baking,drying,tempering,preheating,stereotypes and processing of electronics, electrical, communications, plating, plactics, metal, chemicals, food, printing, pharmaceutical, PC board, power, dipping, spraying, glass, ceramic and building materials and so on.Shandong Leader Machinery Co.,ltd. is located in Jinan of China. We specialized in resource recovery crushing and food machinery Full automatic microwave pumpkin seeds roaster machine for 15 years. Our main products Heavy Duty industrial Commercial microwave oven are food cart, baked oven etc. which is widely used to home or industry.

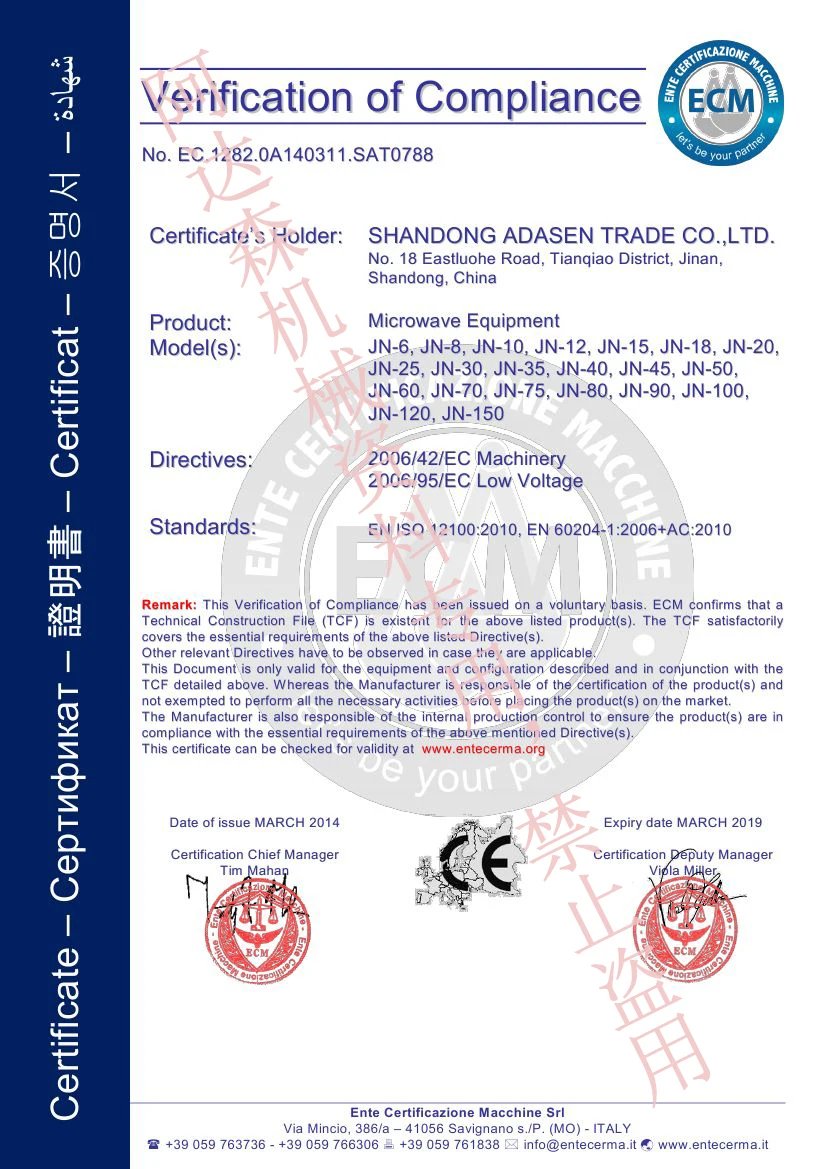

Our production Full automatic microwave pumpkin seeds roaster machine has the characteristics of simple operation, high safety factor and processing good components.Our production has applied for CE certification and has the inventive patent, new practical patent and appearance patent etc. Shandong Leader Machinery Co.,ltd. concept: high quality, complete service and continuous innovation.

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

Email:[email protected]

Whatsapp:+86 13064099546

Skype:leaderfoodmachine21

Contact:Mandy

NOTE:We can specially design the machine according to your production's features.