Industrial microwave dryer Spices Machinery/Paprika Processing Machine/Microwave Chili Powder Drying Machine is used for drying and sterilizing various kinds of food---snack food, agricultural products, fish slice, slice dried meat, bean products, instant noodles, fast food, dried fruit, tea, herbs, karaoke powder, fruit and vegetable in the form of powder, granules, slice, etc.It maximizes the preservation for Shandong Leader Machinery Co.,ltd. activity of materials and vitamins, color & nutrition of food. Spices Microwave Dryer Sterilizer makes the goods drying and sterilizing at the same time.Microwave heating Spices Machinery/Paprika Processing Machine/Microwave Chili Powder Drying Machine is completely different with traditional heating mode. Shandong Leader Machinery Co.,ltd. makes heating medium become heater,Spices Machinery/Paprika Processing Machine/Microwave Chili Powder Drying Machine do not need heat transfer process. Although thermal conductivity is poor materials, also can achieve heating temperature in a very short time.No matter how shape of each part of the body Spices Machinery/Paprika Processing Machine/Microwave Chili Powder Drying Machine, microwave heating all can make the object and evenly infiltration and electromagnetic wave list to produce the heat. So heating good uniformity,Spices Microwave Dryer Sterilizer won't appear the endogenous phenomenon focal.

Spices Machinery/Paprika Processing Machine/Microwave Chili Powder Drying Machine

FEATURE:

1Heating Rapidly and Uniformity

2Energy Saving and Efficient

3.Technology Advanced

Main Features: 1. homogeneous and quick heating

microwave has penetrability and changes with the frequency,the depth of penetration normally from several mm to tens of cm,both the outside and inside of the material can be heated at the same time,therefore avoiding the phenomenon of overheating of the outside while the inside uncooked.Microwave heating changes the heated object to be the heating object,no heat conduction will be necessary.It takes short time for the poor heat conductivity material to reach the heating temperature.The efficiency will be increased greatly by using the microwave,and also the productivity and the quality.

2. Power saving and high efficiency

Material containing water can easily absorb the microwave and be heated,thereby there is almost no loss except the loss during the transporation,therefore high heating effect with low power consumption.

3. Mold proofing,sterilization and freshness keeping

Microwave heating has both heat effect and biological effect,can sterilize and proof mold in lower temperature.Because of the quicking heating within short time,microwave heating can mostly save the activity,color and nutritious parts of the material.

4. Advanced technology with auto-control

The heating and the termination can be realized by the control of the powder of the microwave,there will be no thermal lag.It can be automatically controlled by PLC and human-machine interface.

5. Safety and harmless,the improvement of working environment

The microwave can be controlled in the heat conducting room made of metal and waveguide tubes,so there will almost be no leakage of microwave,no the harm of radition and the disposal of harmful gas,no waste heat and dust,thus greatly improving the working environment and intensity of labour.

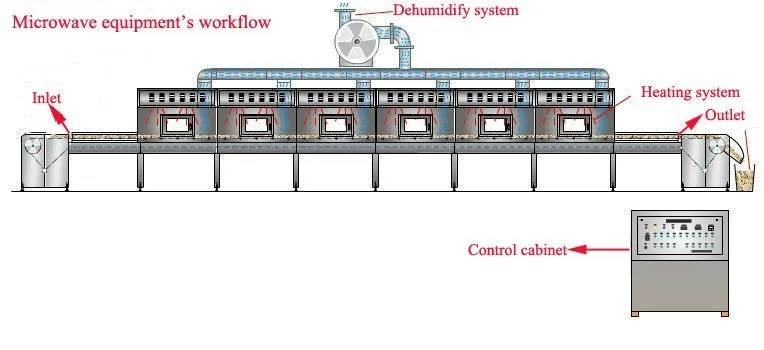

Structure:

The whole machine consists of stainless steel, and it adopts the combined and removable assembly module in several parts:

A.The main body frame;

B.Conveying part;

C.Microwave generator parts;

D.Microwave heating cabinet parts;

E.Microwave preventing leakage parts etc.

The picture of microwave chili powder drying sterilization machine:

Spices Machinery/Paprika Processing Machine/Microwave Chili Powder Drying Machine

Equipment Spices Machinery/Paprika Processing Machine/Microwave Chili Powder Drying Machine warranty period of one year, in addition to human factors failure one year period, the free on-site repair or replacement of parts and the receipt of notice from demand side, supply-side technical maintenance staff will promptly arrived at the scene.Shandong Leader Machinery Co.,ltd. Supplier guide installation, debugging equipment Spices Machinery/Paprika Processing Machine/Microwave Chili Powder Drying Machine to normal operation on site .The supplier free training buyer's operating and maintenance personnel, life-long free to accept the buyer's technical consultation.Life of high quality, low price to provide equipment parts and Spices Microwave Dryer Sterilizer other spare parts.cocoa powder microwave sterilizer Spices Machinery/Paprika Processing Machine/Microwave Chili Powder Drying Machine set up separate total control cabinet, PLC programmable control, human-machine interface display.In the heater outlet equipped with infrared radiation temperature measuring probe, Shandong Leader Machinery Co.,ltd. measuring surface temperature of the material, through the thermometer display material temperature in time, to monitor this case point temperature materials in a timely manner, and can set any temperature, according to the Spices Microwave Dryer Sterilizer required temperature, lower limit setting can automatically adjust the heating tempe.

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

Email:[email protected]

Whatsapp:+86 13064099546

Skype:leaderfoodmachine21

Contact:Mandy

NOTE:We can specially design the machine according to your production's features.