This equipment tunnel type microwave drying machine / dryer used for green tea are widely used for drying and sterilizing powder, granular, flakes or colloidal form foods, nutritional health products, grain, agricultural and sideline products(rice, cornmeal), food, vegetables, and fruits, seafood, pickles,spices ( chilli powder, ginger powder, garlic powder, aniseed, cinnamon, angelica, cassia bark, fennel etc) , jam, Shandong Leader Machinery Co.,ltd. variety of small packaging and pet food mildew sterilization preservation.Shandong Leader Machinery Co.,ltd. is a company specialized in producing twin-screw food extruder, single screw extruder tunnel type microwave drying machine / dryer used for green tea, microwave roasting and tunnel type microwave drying machine / dryer used for green tea sterilization equipments, etc. While based upon domestic market, the company Shandong Leader Machinery Co.,ltd. opens and exploits market Tea Microwave Dryer Sterilizer abroad positively. Until now, our products have been exported many counties and regions, including Russia, Europe, Africa, Korea, Indonesia, UZ (Uzbekistan) and the market share increases gradually year by year. Shandong Leader Machinery Co.,ltd. will continue to be aggressive, creative and make a contribution to our country’s food industry Tea Microwave Dryer Sterilizer development with peers home and abroad.

tunnel type microwave drying machine / dryer used for green tea

1. What is microwave ?

Microwave refers to the frequency of electromagnetic wave 0.3GHz~300GHz, is a band limited radio abbreviation. It has penetrate, reflection, absorption of these three characteristics.

For glass, plastic or porcelain, microwave is almost through without being absorbed. And the self heating for water and food will absorb microwave. And on the metal stuff, it will reflect the microwave.

2. Advantage of microwave used in tea leaf drying

(a) Low temeprature heating , nearly no color change,no nutrition lost ,keep good taste of the tea leaves.

(b) Sterilization. Microwave not only can kill most of the bacteria in the leaf , but also can kill the insect .

(c) Cleaning production,no environment pollution,no dust,no noise pollution.

(d) Save cost .Very fast speed ,only need 2-10 mins , heating the tea leaves throughly and uniformly .Compared with the far infrared heating methods,microwave can save 1/3 of the cost.

(e) Big capacity.The machine is tunnel type ,can meet with continuous production.

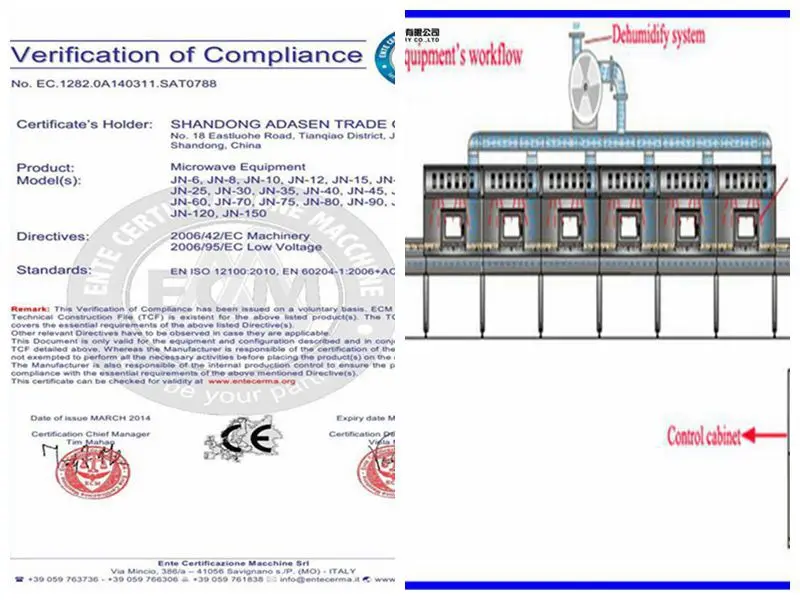

(f) Easy to operate . The control button is installed in the control cabinet, 1-3 people is enough to control it.

3. The experimental comparison of several different drying methods

Table 1 appearance changes of Moringa leaves during different drying processes

(the capacity is 1kg,moisture content is from 65% to 8%)

Drying method | Drying time | Power consumption | Color changes |

Microwave drying | 2min | 0.114kw | Keep green |

Infrared drying | 1h | 3kw | A little yellow |

Freeze drying | 6h | 114kw | Keep green |

Hot air drying | 40min | 23.760kw | A little yellow |

1.From this table we can see that different drying methods has a little effect for the color of the leaves.

2.But the microwave is the shortest drying time and lowest energy consumption drying method (This is mainly because microwave can penetrate through the leaves, and the water can evaporate from the surface and internal of the leaves at the same time . )

3.For freeze drying ,the temperature is ten degrees in the drying process, so also can maintain the color of the leaves,but time is longest and energy consumption is largest,not very practical in the industrial production.

Table2 the nutrients of Moringa leaves by different drying methods

Test item | Microwave | Infrared | Freeze drying | Hot air |

Calcium(%) | 0.67 | 0.64 | 0.71 | 0.65 |

Magnesium(%) | 0.26 | 0.27 | 0.25 | 0.28 |

Iron(mg/kg) | 258 | 150 | 115 | 185 |

copper(mg/kg) | 7.51 | 5.39 | 6.59 | 5.58 |

zinc(mg/kg) | 36.6 | 30.1 | 31.6 | 37.2 |

protein(%) | 21.8 | 22.3 | 20.7 | 23.1 |

fat(%) | 4.15 | 4.87 | 4.92 | 5.25 |

VC(mg/100g) | 355 | 447 | 193 | 192 |

VE(mg/100g) | 14.3 | 11.6 | 7.3 | 7.2 |

VA(mg/100g) | 2.8 | 2 | 2.1 | 2.2 |

1.The effects of different drying methods on metal elements content is not big.

2.But for VC, VE, VA. The microwave drying and infrared drying, for the destruction of the two is the least of them.

3.For the protein and fat,the microwave is the most suitable method.Because now high protein, low fat products are most popular.

4.But time of the infrared drying is longer than microwave drying.And consumption is larger than microwave drying method too.

5.So from these experiments and analysis,we can see the microwave drying machine is the most suitable method for moringa.

4.The machine can be designed according to your requirement.

5. Packaging picture ,use standarding wooden box , Be fumigated

6. Shipping

Transportation : By vessel

Delivery port : Qingdao

Our Services

Warranty : While delivering machine,we will provide 2 sets spare parts freely. For the whole equipment,warranty is 12 months,within 12 months,if have equipment quality problems , we will provide accessories freely.After expiration of the warranty period,if have spare parts problem, we only receive the cost of required replacement parts.We commit we will provide free technical support of the equipment all whole life .

Company Information7. Why you choose ADASEN Microwave Dryer :

Microwave company is a hi-tech enterprise that is emgaged in professional developing ,producing and selling on microwave energy applying equipment,which is one of the biggest sclae microwave energy equipments manufacturer in China now.

In line with Microwave sprit of science ,factualistic ,prestigious and sincere,gathering the local and foreign top--grade talented person and elite ,depending on strong technique strength,completed examination means,science management and good quality-protecting system,our special brand--"ADASEN" microwave equipment are very famous in China with its superior quality ,also been exported to Europe,America,Middle East,Southeast Asian etc countries and regions.

FAQ

1.The machine forbid to be opened when the heating box has no material in it .

2.The metal and sealing articles cannot be heating in the microwave.Because metal has reflection effect on magnetron , the sealing articles easy to cause explosion when the temperature rising.

3.Cleaning equipment regularly .

4.Regularly check whether the observation window has bump phenomenon , because this phenomenon easy cuase microwave leakage .

8. Our customers

Microwave tea leaf dryer ,makes the leaf nearly no color change ,no nutrition lost . fast speed ,save cost ,your best choice , please don't hesitate to click the below dialog box and send message to me for more details!!!

This tea drying machine tunnel type microwave drying machine / dryer used for green tea for sale is widely used for the heating and dehumidification of raw materials and Shandong Leader Machinery Co.,ltd. product in pharmaceutical,chemical, foodstuff, light and heavy industries. Especially for the fruit and vegetable food processing.such as leaf vegetables, cabbage,onions,carrot, apples,

lemons,orange,pulms,bananas,pineapples,etc.Use hot air circulation blower to dry the material , Fan wheel rotates, the outside air into the oven,After heater, Tea Microwave Dryer Sterilizer hot air is formed,Then enter the working chamber through the air distribution plate gap , A lot of hot air Tea Microwave Dryer Sterilizer inside the circulating flow, Continue to enter new air inlet supplement.After the recycled exhaust moisture from the exhaust port.Whole cycle, so that the material is heated uniformly, and the purpose of drying.

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

Email:[email protected]

Whatsapp:+86 13064099546

Skype:leaderfoodmachine21

Contact:Mandy

NOTE:We can specially design the machine according to your production's features.