Shandong Leader Machinery Co.,ltd. 2016 First level almond oil mill adopts the most advanced technology, high efficiency, its.Its strong maintain ability and high make this cotton seeds oil solvent extraction production line very popular aroud the world.Adopt stainless steel fixed grid plate and increase the horizontal grid plates, which can prevent the strong miscella from flowing back to the blanking case, so as to ensure good extraction effect;

Almond OiLDtailed Images

Almond oil mill Flow:

almond seedâÂÂMeteringâÂÂCleaningâÂÂStone separatorâÂÂCrusherâÂÂSofteningâÂÂFlakerâÂÂCookingâÂÂ

Pre-pressâÂÂ-Pressed cake goes to extraction t

â Crude oil filterâÂÂto the refining plant

Title goes here.

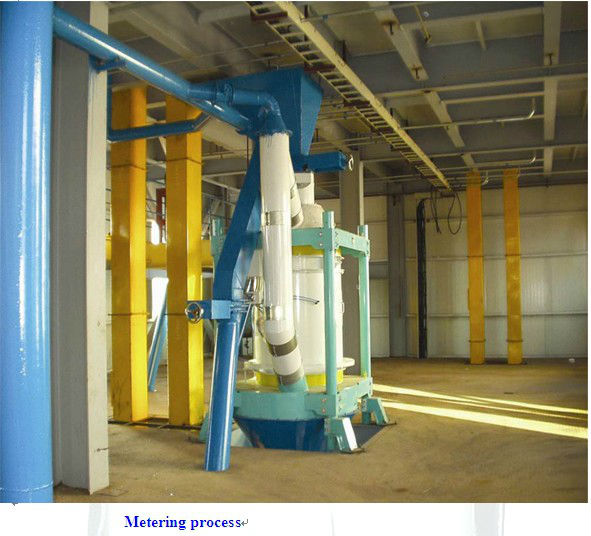

1.Metering process: with special equipment, the stable measuring scale is used to regulate the flow and measure total production. Moreover, it can achieve accumulated measurement, transient measurement and cost accounting, with accurate measurement and high precision.

1. Middle measuring equipment with High speed and high precision for powder and partical material

2.Automatic measuring and accumulative total, there is no need manual operation

Cleaning: In order to obtain high effective cleaning, ensure good work condition and production stability, high efficient vibration screen was used in the process to separate big and small impurity. Suction type gravity stoner removing machine was applied to remove the shouLDr stone and earth, and magnetic separation equipment without power and exhaust system were used to remove iron. Dust removing wind net is installed. The dedusting system uses single union cyclone and centrifugal fan to remove dust effectively, so as to to ensure workshop hygiene and clear light impurities.

Destoner:It was used to remove the stones which have the same size as s or high density impurities, and used to remove the light impurity in the material auxiliarily. It has two insert frame, and upper used to grading, and the bottom used to remove the stone, high capacity, high effect. The dip angle of the sifter could be adjusted, and the amount of air sucking could be adjusted. Screw spring support and rubber spring support, operate steadily, low consumption. Unique to guard against theft system,(patent number ZL201020577278.2), There is no material discharge when stop.

The key equipment of Almond oil mill

When oil press operating, the prepared materials enter the pressing chamber from the hopper and then move forwards by the rotating of pressing screw and is pressed under the high-pressure condition in the chamber, friction between material and chamber will be created, which also created friction and relative movement among material particles, on the other hand, root diameter of the pressing screw carries larger from one end to the other.

Steaming and frying refers to the green after wetting, heating, steam, fry stock, such as processing, become a medium grey process.The purpose of cooker: 1. Make oil condensation;2.Adjust the organization structure of billet material;3.Improving the quality of oil.

Packing & Delivery

Our Company

Our Company

LD Group:

LD and oil machinery co., LTD is a company specializing in the production of and oil machinery and equipment, scientific research, manufacturing, sales for the integration of large-scale private enterprises, the company with the mechanical design and research institute of LD province, LD university of technology (the former college of food) university-enterprise cooperation, carried out for a long time in oil machinery, preparing protein, lecithin extraction and other aspects of the research and development and application of new technology.

Company has oil machinery design institute, the ministry of oil press, large oil complete sets of equipment, international trade, machinery and equipment production.Business involves the small oil mill series, and oil engineering design, equipment manufacture and installation, project contracting, technical services, new product development, oil by-products deep processing, etc.

Company is located in the capital of LD province, LD national hi-tech industrial development zone, covers an area of 27000 square meters, has 12 standardization of heavy industrial production workshop, a variety of large and medium-sized gold processing, maohan, assembly equipment more than 100 sets, on-line more than 200 employees, among them with medium and senior title of professional management personnel and engineering and technical personnel more than 60 people.

Contact Information

Contact InformationSales Manager: Annie Lee

Tel: +86 15237168511

Whatisapp: +86 15237168511

Skype: goldpenguin9713

Wechat: muzi5279

2. 2016 First level almond oil mill is driven by rack, with unique rotor of balanced design, low rotating

speed, low power, smooth operation, no noise and quite low maintenance cost;

3. The feeding system can adjust the rotating speed of airlock and main engine according to the

feeding quantity and maintain a certain material level, which is beneficial to the micro negative

pressure inside the extractor and reduce the solvent leakage.;

AAA1

The advanced 2016 First level almond oil mill is designed to reduce the fresh solvent inputs,

reduce the residual oil in meal, improve the miscella concentration and save energy by reducing

the evaporation capacity;

The high material layer of the extractor helps to form immersion extraction, reduce the meal

quality in miscella, improve the quality of crude oil and reduce the evaporation system scaling;

Specially suitable for the extraction of various pre-pressed meals.

AAA2

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: [email protected]