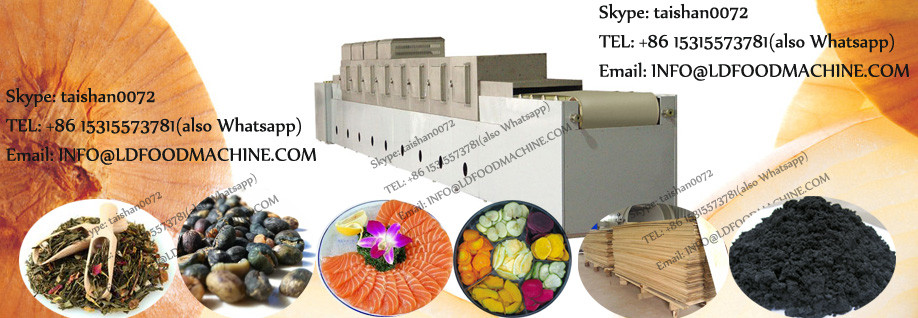

rotary kiln dryer

Introduction of rotary dryer:

Rotary dryer is a drying device, widely used in mining equipment. It can be divided into two categories, direct and indirect heat transfer drum dryers.

Structure of rotary dryer:

In order to increase the material evenly distributed in the rotor parts of the cross section in good contact with the drying medium, in the cylinder body installation raise plates. There are several types of raise plate.

1). lifting type: For large or easy to bond the material in the tube wall.

2).Four formats type: Suitable for big density, not crisp or not easily scattered materials. The raise plate will be divided into four panes, and were mutually connected fan-shaped workout room, Materials and the contact surface of the hot gas than large of the lifting type, and also can increase of the filling material rate and reduce material landing height and reduce dust quantity loss and so on.

3).Cross-shaped or frame-shaped: applicable to brittle and easy dispersion small pieces of material, make the material can be evenly dispersed in cylinder whole section.

4).Sleeve type: For double entry Heat transfer for the double (or half the diameter heating) rotary drum dryer raise plate.

5).Separate format (fan): For very fine particles and the material prone to flying powder. materials accumulate on grid board when it into, then cylinder rotates, the material is turning and continue contacts with the hot gases, at the same time, the decrease of height landing, reducing the dry material being gas away possibility.

Advantages of rotary dryer:

The dryer has advantages of reasonable structure, high efficiency, low energy consumption and convenient transportation.

Application of rotary dryer:

Rotary dryer is used to dry slag, clay, limestone; it is mainly used for cement, chemical, metallurgical, building materials industries

Working principle of rotary dryer:

The auto-combustion device provides heat resource for our rotary dryer, which adopts down-flow heating method. When the mineral materials are fed into the cylinder, it flows down as a result of gravity. Meanwhile, they are repetitively scattered in the air so that they are in full contact with the hot air. The material is thus dried gradually.

|

Capacity(t/h) |

Main motor |

Main gear box |

Weight(t) |

||

Power(kw) |

Model |

Model |

Speed reduction ratio |

|||

ø1.2*10 |

2.5 |

7.5 |

Y160M-R3 |

ZL50-16-I |

----- |

13.5 |

ø1.5*12 |

3.3-4.9 |

10 |

Y160L-6-B3 |

JZQ500-III-2F |

----- |

18.9 |

ø1.5*15 |

4-6 |

18.5 |

Y200L1-6 |

JZQ500-III-2F |

----- |

21 |

ø1.8*12 |

4-6 |

18.5 |

Y160L-6 |

ZQ50-16II-2 |

16.46 |

22.83 |

ø2.2*12 |

7-12 |

18.5 |

Y200L7-6 |

JZQ650-III |

31.5 |

37.6 |

ø2.2*14 |

7-12 |

22 |

Y200L7-6 |

JZQ650-III |

31.5 |

40 |

ø2.2*16 |

12 |

30 |

Y225M-6 |

JZQ750-III |

31.5 |

45 |

ø2.4*14 |

12 |

30 |

Y250M-6 |

JZQ750-III |

31.5 |

51 |

ø2.4*18 |

10-13 |

37 |

Y250M-6 |

ZL85-13-I |

27.16 |

54 |

ø2.4*20 |

10-14 |

37 |

Y250N-6 |

ZL85-13-I |

27.16 |

54.14 |

ø3*20 |

25 |

55 |

Y250M-4 |

ZL100-16-I |

41.52 |

78 |

ø3*25 |

32-36 |

75 |

YR280M-4 |

ZL100-16-I |

41.52 |

104.9 |

| Application of rotary dryer: |

Rotary dryer is used to dry slag, clay, limestone; it is mainly used for cement, |

| Working principle of rotary dryer: |

The auto-combustion device provides heat resource for our rotary dryer, which adopts down-flow heating method. When the mineral materials are fed into the cylinder, it flows down as a result of gravity. Meanwhile, they are repetitively scattered in the air so that they are in full contact with the hot air. The material is thus dried gradually. |

|

Established in the 1970s, Henan Yuhui Mining Machinery Co., Ltd. has developed into a famous manufacturer through 40 years' struggling and progressing, specialized in producing mineral dressing equipment, compound fertilizer equipment, cement equipment, as well as sand making equipment. |

A Company You Can Trust: |

|

Henan Yuhui Mining Machinery Co, Ltd. is located in Zhengzhou City in central plains, which adjoins to ancient millennium Shaolin Temple (Kongfu Origin) to the south, and Yellow River to the north. With Lianhuo highway and Longhai railway, it owns convenient transportation and pleasant scenery. |

Quality and Safety: |

|

Our company is devoted to providing advanced and economical technical devices with modern enterprise management mechanism, first-class processing equipment, perfect test means, high quality research experts and high quality follow-up services. Our company has been honored as "Advanced Quality Management Corporation" and "high Reputation Corporation". Our products have been selected as "premium brand" products. |

Q1.Is your company a manufacturing company and do you have a company certificate? |

|

A: Yes, our company is a manufacturing company and we are specialized in mining machine for more than 40 years with two factories. Our company has owned the certificate of ISO9001:2000. |

Q2. Where are your products mainly exported? |

|

A: Our products are distributed throughout the world, being involved in more than Asia, Africa and South America countries and regions. And our products win the good reputation of our foreign customers. |

Q3. What’s the additional features of your company? |

|

A: We have our own laboratory in the company, so the clients can take some samples to perform experiments on the spot. And our engineers will provide the best advice and choice for our clients. |

Q4. Welcome to our company: |

A: We have stone production line, sand-making production line and so on. The clients can visit our production site. |

Q5. How do you guarantee your after service? |

|

A: Our company guarantees repair, replacement and refund and it is warrantable to the complete machine for 12 months. And we can design the site for free and provide basic materials, assembly drawings and equipment installation technical services. At the same time, we provide a connected sequence services with directing civil engineering on spot, installing and debugging the equipment, training technical and operating people broad. Also, our engineers are assured be sent to work broad for a long period. Our company supplies accessories for a long period, and lifetime warranty |