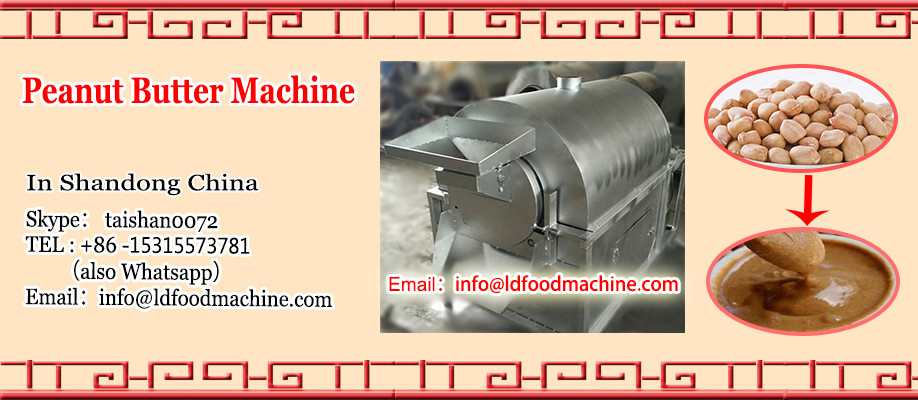

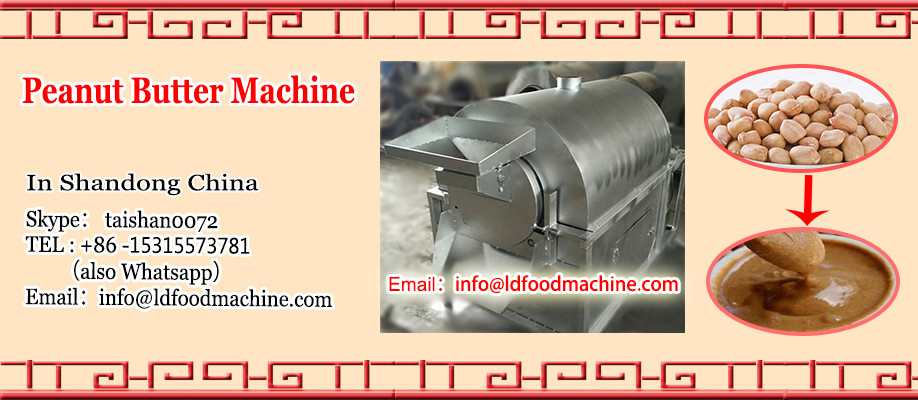

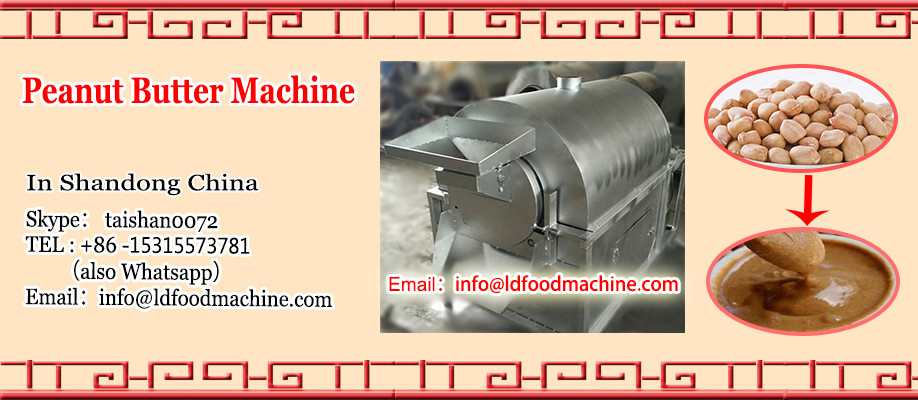

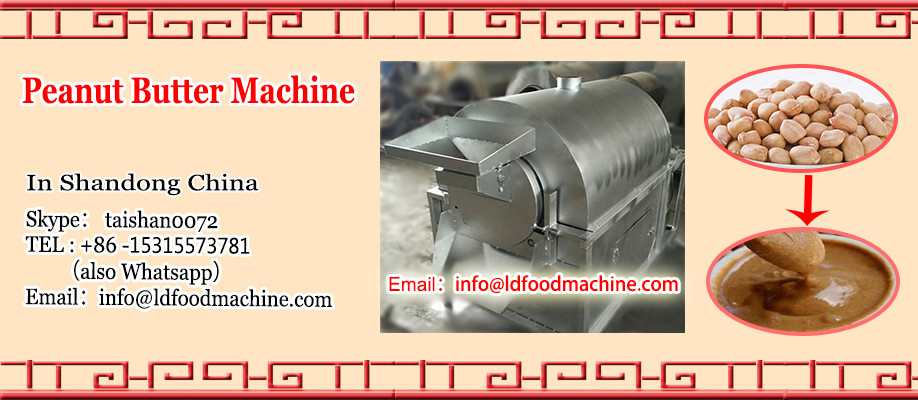

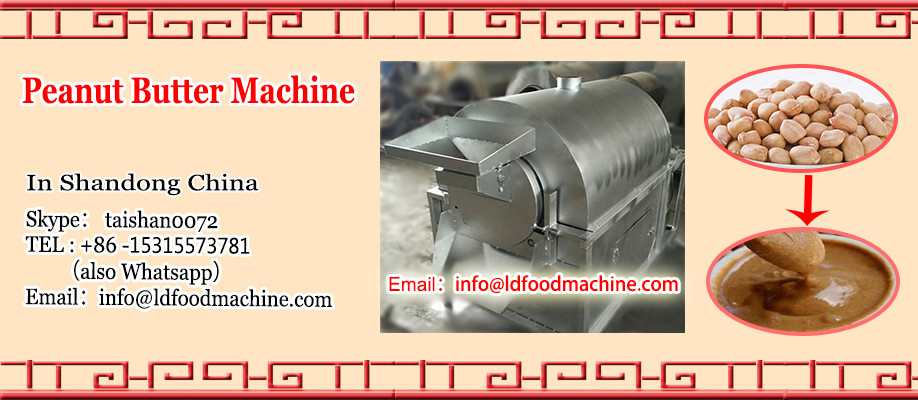

Peanut Butter Maker machinery

1. Peanut Butter Maker machinery is a fine-fluid materials processing .

The machinery is well desityed,stability performance,simple operation,easy maintained.

2.Applications

a.Food industry: Aloe vera,Pollen,pine pie,sesame,fruit tea,ice cream,moon cake stuffing,butter,jam,fruit juice,soybeans,soybean,Paste,red bean,peanut milk,protein milk,soy milk,dairy, Products,wheat milk essence,flavor,Variety of drinks,chicken,Mud,pig and other animal hides.

b.Chemical industry: Paints,pigments,LDes,paints,lubricants,grease,diesel,petroleum catalyst,emulsified althalt,adhesives,detergents,plastics,explosives,glass,steel,leather,Emulsion explosives.

c. Daily Chemical: Toothpaste,detergent,shampoo,shoe polish,cosmetics,Bath essence,soap,balsam etc..

d. Pharmaceutical industry: All kinds of syrup,nutrition,medicinal paste Pharmaceutical,biological products,cod liver oil,pollen,royal Jelly,vaccines,various creams,a Variety of oral, injection,Intravenous fluid, pancreatic enable preparations, emulsions,etc..

3.Usage of the Peanut Butter Maker machinery:

When install the machinery well and connect the power,operate the machinery according the following process:

1. Check weather the blots are screwed up. (The blots for tight the rotor should be M12 L-bodys)

2. Counter-clockwise rotation two fixed link.(Loosen the locLD fixed link)

3. The adjustment ring to the counterclockwise rotation of not less than 90 ° (the stator and rotor clearance Adjust)

4. Rotating rotor with a special wrench to check whether the stuck rotor phenomenon. If the case is not allowed to boot.

5.Open the switch)

1/check the rotor ratating diretion,should be same as the direction on the machinery(Clockwise)

notes: the direction mistake will cause the rotor fastening body loose or drop down,more seriouLLD,will damage the machinery.

2/check the machinery operating situation: whether there is vibration or noise,if yes,should check at once,settle the trouble and start the machinery

6.According to the cooling water sity,connect the water. The cooling water tube can use plastic tube diameter φ10mm

4.Notes:

1/the equipment can not process dry solid material,only process wet material.

2/ the input material size should be less than 3mm,before material

Is put into equipment,should remove the unwanted things,not allowed iron particle or smal stone come into the machinery in case to damage the machinery

3/according to the material characteristics and finesse requirement,can process the material for one time or many times.

5.Equipment Washing:

The adjustment ring counterclockwise rotation of not less than 90 ° (the gap Adjust the stator and rotor).Add water.Note: equipment cleaning should be carried out under the machinery running conditions.

6.if you can not use the machinery in the short time,should clean the inside in case of corrision,and blow it dry with high pressure air. When cleaning should choose suitable cleaning agent according to different raw material,make sure not damage the Seals(Sealing material NBR)

Main Technical Parameter of:

Model |

LG-50 |

LG-80 |

LG-110 |

LG-130 |

LG-180 |

LG-240 |

LG-300 |

Final size of products |

2-50 |

|

Capacity ( t/h)

|

0.005-0.03 |

0.1-0.5 |

0.3-1.2 |

0.4-2.0 |

0.8-6.0 |

4.0-12 |

6.0-25 |

Main power KW |

1.5/1.1 |

4 |

7.5 |

11/15 |

18.5/22 |

37/45 |

75/90 |

Dimension |

Length mm |

520 |

685 |

700 |

975 |

981 |

1319 |

1440 |

Width mm |

250 |

335 |

430 |

456 |

476 |

500 |

630 |

Height mm |

555 |

928 |

1000 |

1054 |

1124 |

1276 |

1420 |

Weight (kg) |

70 |

210 |

300 |

400 |

420 |

1000 |

1600 |

Note: usually is the standard motor,if the client need special requirements should note in the contract.

Detailed pictures of Peanut Butter make machinery:

![]()

![]()

![]()

![]()

Certifications![]()

![]()

Company Information![]()

Contact Us Yoursatisyaction is our biggest goal.

![]()